Soft plastic molding is a sport-changer in the production world. It offers flexibility, precision, and performance, particularly for growing custom merchandise and prototypes. This approach is ideal whether you want a one-of-a-kind design or a take-a-look-at version. Let’s explore why gentle plastic molding offerings are perfect and how they gain numerous industries.

What is Soft Plastic Molding?

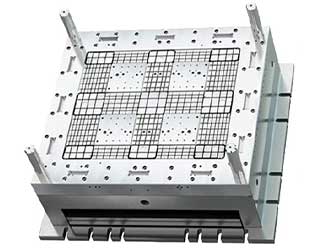

Soft plastic molding is a process in which liquid plastic is formed into molds. These molds create products with exact designs, soft finishes, and excessive accuracy. Custom plastic molding solutions, like silicone or thermoplastics, are used. These materials are bendy, long-lasting, and clean to work with.

Why Choose Soft Plastic Molding for Custom Products?

Precise Designs

Flexible plastic manufacturing is great for making specific shapes and complex information. The molds can produce sharp edges, small components, and unique patterns, essential for industries like clinical devices, toys, and electronics.

Quick Turnaround Time

Custom merchandise frequently wants to be made quickly. Soft plastic molding is speedy. Once the mildew is ready, manufacturers can produce many items rapidly. This helps corporations meet tight time limits.

Cost-Effective

Custom objects may be expensive, but tender plastic molding facilitates lower expenses. The molds are reusable, and the method calls for less material waste, making it a financially pleasant preference for small and large businesses.

Flexible Options

Silicone molding for prototypes works with unique substances, hues, and finishes. This flexibility allows you to create merchandise that ideally shapes your imagination and is prescient. From soft grips to clean cases, the opportunities are endless.

Why is Soft Plastic Molding Ideal for Prototypes?

Test and Improve

Prototypes are trial variations of products. They help businesses evaluate designs before mass production. Soft plastic molding makes it easy to create prototypes quickly. If changes are desired, the mildew can be adjusted.

Low Risk

soft plastic molding makes producing a prototype less risky. The procedure uses fewer assets and is affordable, so you can test your idea without worrying about losing money.

Realistic Results

Prototypes made with Injection molding services look and feel like the final product. This is important when providing designs to customers or traders. A sensible prototype allows for building consideration and confidence.

Industries Benefiting from Soft Plastic Molding

Healthcare

Plastic prototyping techniques is used to make clinical gadgets such as syringes, tubing, and prosthetics. Its precision guarantees safety and excellence.

Automotive

Car manufacturers use this approach for gaskets, seals, and interior components. The durability of tender plastics is a massive advantage.

Consumer Goods

From cellphone cases to kitchen gear, tender plastic molding is everywhere. Its versatility allows for innovative and purposeful designs.

Toys

Toys require vivid hues, specific shapes, and toddler-secure substances. Durable thermoplastic molding effectively meets some of these wishes.

How to Choose the Right Soft Plastic Molding Service

- Check Experience: Look for an employer with an excellent song record. Experienced vendors recognize the manner and might manage demanding situations.

- Review Materials: Make sure they provide the proper substances for your venture. Different plastics are better for particular designs and uses.

- Ask About Customization: Choose a carrier that permits unique customization. You want your product or prototype to stand out.

- Consider Cost and Speed: Ask approximately production time and pricing. The right provider will deliver great without breaking your price range.

The Future of Soft Plastic Molding

Soft plastic molding continues to adjust to new advances. High-level strategies like 3D printing and biodegradable plastics make the interaction more effective and eco-accommodating. Businesses that spend money on gentle plastic molding benefit from an aggressive aspect in creating modern and sustainable products.

Who is the Best Soft Plastic Molding Services Provider in China?

If you’re looking for first-rate soft plastic molding services in China, EX MOULD Co. is the top choice. They specialize in creating outstanding custom merchandise and prototypes. Their team uses superior technology and sturdy substances to deliver specific outcomes. Whether you need soft plastic elements for clinical, automotive, or client goods, EX MOULD Co. has you covered.

What sets them aside is their dedication to purchaser pride. They offer rapid turnaround instances and bendy solutions tailor-made to your wishes. Their eco-friendly method ensures minimum waste, making them an extraordinary preference for sustainable production.

FAQs

What varieties of plastics are utilized in soft plastic molding?

Soft plastic molding frequently utilizes silicone, thermoplastics, and elastomers, which are bendy, strong, and adaptable.

Is soft plastic molding suitable for small agencies?

Yes, it’s miles. The procedure is fee-effective perfect for startups and small corporations seeking custom products.

How long does it take to supply a prototype with tender plastic molding?

The time depends on the complexity of the design. However, soft plastic molding is quicker than many different methods. Most prototypes are ready in days or weeks.

In Wrap up the Soft Plastic Molding Service

Soft plastic molding services are the proper desire for custom products and prototypes. They offer precision, speed, and affordability. Whether you’re in healthcare, toys, or a car, this approach gives limitless opportunities. By selecting the right provider, you can readily deliver your thoughts to life.

Precision plastic molding process is shaping the destiny of manufacturing. Now is the time to discover its potential for your subsequent project.