18

2025.4

All About Insert Injection Molding: Considerations, Applications

Insert injection molding is a smart way to make strong plastic parts. It mixes plastic with other solid materials like metal. This method is used in many industries, such as cars, electronics, and even medical tools. If you sell or use molded products, understanding metal inserts in injection molding can help you make better choices. We’ll talk about what insert injection molding is, how it works, and where it’s used. We will also explore the process, important th......

18

2025.4

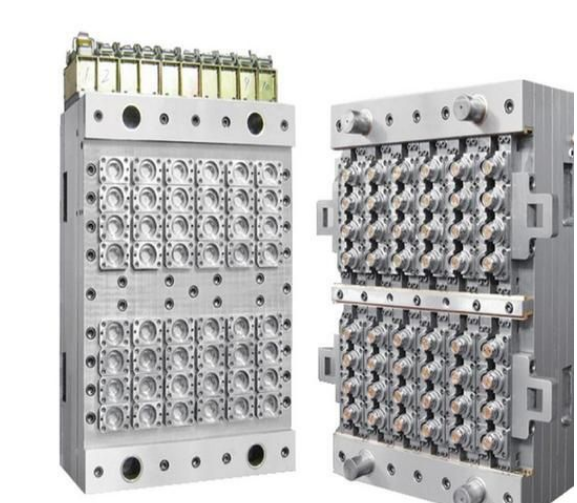

How Do I Choose the Right Injection Blow Molding Partner

Choosing the right Injection Blow Molding partner is a big decision. The Injection blow molding company you pick will shape your product’s quality, delivery time, and cost. Whether you’re making bottles, jars, or small plastic containers, the professional blow mold manufacturer can help your business grow. But how do you find a company you can trust? This guide will help you learn what to look for in an Injection Blow Molding company. We’ll also introduce yo......

11

2025.4

Can Silicone Mold Manufacturers Create Custom Designs

Silicone molds are tools made from soft but strong materials. These molds help shape different items in many industries. You can find them in factories, homes, and even in kitchens. But what if you want a mold made just for your product? Can silicone mold manufacturers create custom designs? Yes, they can! We’ll explain how this works, who uses these molds, and how to choose the right custom silicone mold maker. We’ll also highlight a top company in China—EX MOULD......

11

2025.4

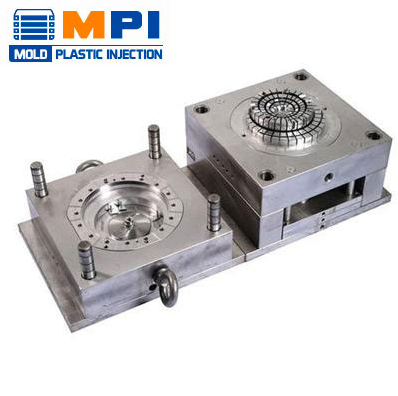

Resin Plastic Injection Molding: Types, Advantages, Applications

Have you ever wondered how plastic toys, phone cases, or car parts are made? Most of them come from a smart method called resin plastic injection molding. This method is fast, powerful, and used all around the world. It helps create strong, neat, and useful plastic items we use every day. Learn what resin plastic injection molding is, what types of resins are used, why this method is popular, and what kinds of products it helps create. What is Resin Plastic Inject......

4

2025.4

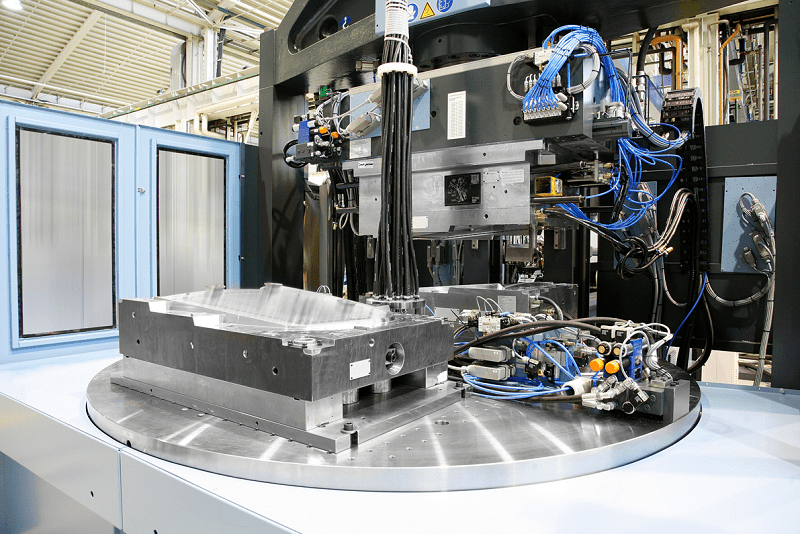

Where Are Hot Runner Plastic Injection Molds Used

Plastic injection molding plays a major role in manufacturing. Many industries use this process to create particular and durable plastic parts. One of the maximum superior hot runner systems in plastic injection molding is the ultra-modern runner system. It improves ordinary overall performance and reduces waste. But where exactly are heat runner plastic injection molds used? We’ll explore their applications, benefits, materials, and where to buy them. What is a H......