If you’ve ever wondered how the plastic bottles you use daily are made, the answer lies in the plastic bottle manufacturing machine. These machines are vital in shaping plastic into bottles in homes, shops, and offices. But which moulding gadget is used to make bottles? In this article, we’re able to find out the number one form of molding device used for bottle production: automated blow molding systems.

What is Blow Molding?

Blow molding is the maximum, not unusual, approach for making plastic bottles. This method properly shapes heated plastic into a hollow shape by inflating it with air. The save you cease, save you give up stop result is the acquainted shape of bottles that we see spherical us. Blow moulding is eminently used as it’s fast, compelling, and remarkable for large-scale manufacturing.

There are three fundamental types of blow molding: extrusion, injection, and stretch. Each kind serves a wonderful purpose, but all are critical to PET bottle production worldwide.

Types of Blow Molding Machines

Let’s look at each blow molding device utilised in making bottles.

Extrusion Blow Molding (EBM) Machine

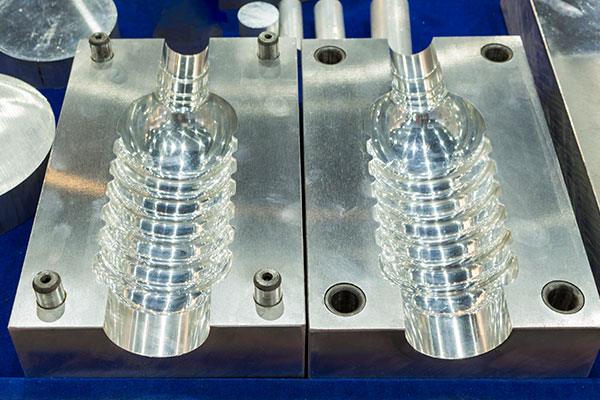

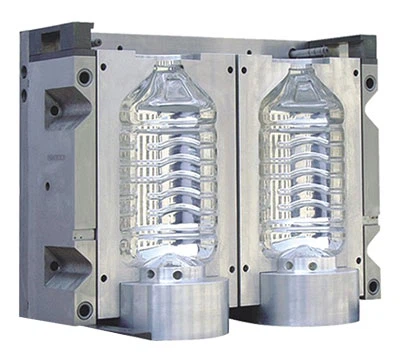

In the extrusion blow moulding, plastic is first softened and typically used to frame a cylinder called a “parison.” This parison is cinched in a mold, and the air is blown into it. The air pushes the plastic towards the mold walls, fostering the state of the jug. The buildup opens after cooling, and the jug is sent off.

Advantages of extrusion blow molding:

- It is exceptional for making significant and complicated bottles.

- It allows for a wide variety of sizes and styles.

- The method can cope with specific varieties of plastic.

Injection Blow Molding (IBM) Machine

Injection blow molding begins offevolved by the usage of using way of injecting melted plastic proper right appropriate into a preform mold to create a strong carryout. This preform is then transferred to a blow mildew in which air is injected. The air pressure causes the preform to boom into the bottle shape.

Advantages of injection blow molding:

- It is proper for smaller, more uniform bottles.

- It produces bottles with clean, beautiful finishes.

- This approach works efficaciously with substances like PET (polyethene terephthalate) frequently applied in water and soda bottles.

Stretch Blow Molding (SBM) Machine

Stretch blow molding is a two-step method. First, plastic is properly injection-molded into a preform, much like the IBM technique. Then, the preform is reheated, and air is blown into it simultaneously because the plastic is stretched. This stretching complements the electricity and clarity of the bottle.

Advantages of stretch blow molding:

- It creates moderate-weight and robust bottles.

- It’s extremely good for extraordinary merchandise like water and soda bottles.

- Stretching the plastic offers it a more prominent and shinier appearance.

Which Molding Machine is Best for Making Bottles?

Choosing the suitable molding device is based on the bottle shape you want. An extrusion blow molding system is ideal for large and further complex bottles. If you need smaller, excessive-precision bottles, injection blow molding is an excellent choice. On the other hand, if you’re aiming for mild-weight and crystal-easy bottles, stretch blow molding machines are top-notch.

Each device has exceptionally non-public strengths, and manufacturers choose the excellent brilliant that suits their product requirements. For ordinary plastic bottles, stretch blow molding is the most unusual method because of its everyday widespread ordinary performance and the first-rate bottles it produces.

Injection molding equipment Used in Bottle Production

Different plastics are used for making bottles. Some of the most commonplace embody:

- PET (Polyethylene Terephthalate) is a durable, moderate-weight, smooth plastic Used for water and soft drink bottles.

- HDPE (High-Density Polyethylene): Found in milk containers and cleanser bottles. HDPE is robust and durable.

- LDPE (Low-Density Polyethylene): Used for press bottles. LDPE is adaptable and clean.

The cloth chosen is based entirely on the bottle’s use. For example, a drinking water bottle desires to be clean and lightweight, so PET is a terrific choice.

How Does the Bottle Production Process Work?

- Melting the Plastic: The plastic fabric, in the shape of pellets, is heated until it melts.

- Shaping the Plastic: The molten plastic is modern proper right right right right into a preform or parison, counting on the shape of blow molding.

- Blowing the Bottle: The preform or parison is placed in a mould, and air is blown into it to shape the mildew.

- Cooling: Once the bottle has taken shape, it is cooled to harden.

- Finishing Touches: The bottle is eliminated from the mildew, trimmed, and prepared for use.

China’s Top Plastic Injection Mold Manufacturer?

When searching out China’s best plastic injection mould producer, EX MOULD Co is a leader in the industry. They are known for producing extraordinary injection molds implemented in several sectors, including automobile, electronics, and circle of relatives merchandise. With an advanced generation and a professional employer, EX MOULD Co ensures precise molds that meet global necessities.

Their information in mould format and production makes them the go with the flow-to organisation for companies searching out reliable and robust plastic molds. Whether you need a clean layout or a complicated mould, EX MOULD Co guarantees on time with tremendous consequences.

The Final Words

The stretch blow molding technology of growing bottles is fascinating and pretty inexperienced. Blow molding machines—in particular extrusion, injection, and stretch blow molding machines—play an essential role in developing the bottles we use each day. Depending on the form of bottle desired, producers select the right tool to offer the right surrender result.

FAQs

What is the most commonplace device used to make plastic bottles?

The most unusual tool is the stretch blow molding machine, which makes PET bottles for drinks like water and soda.

What materials are carried out in bottle-making machines?

Normal substances incorporate PET for water bottles, HDPE for milk jugs, and LDPE for crushed bottles. Each cloth has a lovable domestic, depending on the bottle’s use.

Why is blow molding used to make bottles?

Blow molding is rapid, inexperienced, and remarkable for making holes, as well as mild-weight gadgets like bottles. It furthermore permits mass manufacturing at a discounted rate.