Plastic bottles are all around us. We use them every day for drinks, cleaning products, and many other things. But have you ever wondered how these bottles are made? The answer is molding. This article will explain the different types of molding used to make plastic bottles. We will also learn about the process and why it is important.

What is Molding?

Molding is a process used to shape materials into different forms. When it comes to plastic bottles, molding is the method used to create their shape. There are different types of molding, but not all are used for making plastic bottles. The most common types are injection molding and blow molding. Let’s dive into these methods.

Common Types of Molding is Used to Make Plastic Bottles

Injection Molding

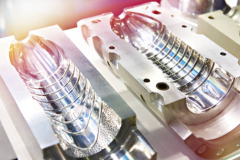

Injection molding is a popular method for making many plastic items. However, it is not the main method for making plastic bottles. Instead, it is used to make the preforms. Preforms are small plastic tubes that will later become plastic bottles. Here is how the process works:

- Melting the Plastic: The process starts by melting plastic pellets. These pellets are small pieces of plastic.

- Injecting the Plastic: The melted plastic is then injected into a mold. This mold shapes the plastic into a preform.

- Cooling Down: The preform cools down and hardens.

- Ejecting the Preform: Once the preform is hard, it is ejected from the mold.

The preforms look like test tubes with thick walls. They are then sent to the next stage to become full-sized plastic bottles.

Blow Molding

Blow molding is the main process used to make plastic bottles. There are two main types of blow molding: extrusion blow molding and injection blow molding.

Extrusion Blow Molding

- Extrusion blow molding is used for making larger plastic bottles. Here is how it works:

- Extruding the Plastic: First, plastic is melted and extruded into a tube, called a parison.

- Clamping the Mold: The parison is placed between two halves of a mold. The mold then closes around the parison.

- Blowing Air: Air is blown into the parison, which makes it expand and take the shape of the mold.

- Cooling Down: The plastic cools down and hardens into the shape of a bottle.

- Ejecting the Bottle: The mold opens, and the new plastic bottle is ejected.

This method is perfect for making large plastic bottles, such as those used for detergents and shampoos.

Injection Blow Molding

Injection blow molding is used to make smaller bottles. This method combines injection molding and blow molding. Here’s how it works:

- Making the Preform: First, a preform is made using injection molding, just like we discussed earlier.

- Heating the Preform: The preform is heated to make it soft.

- Blowing Air: The soft preform is placed in a bottle-shaped mold. Air is blown into it, making it expand to fit the mold.

- Cooling Down: The plastic cools down and hardens into the shape of the bottle.

- Ejecting the Bottle: The mold opens, and the new plastic bottle is ejected.

This method is great for making small bottles, like those used for water, soda, and other drinks.

Why is Molding Important?

Molding is important because it allows manufacturers to make plastic bottles quickly and efficiently. It also ensures that each bottle is the same size and shape. This consistency is crucial for packaging and transporting the bottles.

Using molding also reduces waste. The plastic that is not used in one bottle can be melted down and used again. This makes the process more environmentally friendly.

The Benefits of Plastic Bottles

Plastic bottles have many benefits. They are lightweight, which makes them easy to carry. They are also strong and durable, which means they do not break easily. This makes them perfect for storing liquids.

Plastic bottles are also recyclable. After we use them, they can be melted down and made into new bottles. This helps reduce waste and protect the environment.

Final Thoughts

Molding is the key process used to make plastic bottles. Injection molding and blow molding are the main methods used. Injection molding creates preforms, which are then shaped into bottles using blow molding. Extrusion blow molding and injection blow molding are the two main types of blow molding.

FAQs about Molding for Plastic Bottles

What is the difference between extrusion blow molding and injection blow molding?

Extrusion blow molding is used for making larger bottles and involves extruding plastic into a tube and blowing air to shape it. Injection blow molding is used for smaller bottles and combines injection molding to create a preform, which is then blown into the final bottle shape.

Why is molding important for making plastic bottles?

Molding is important because it allows manufacturers to produce plastic bottles quickly and efficiently, ensuring each bottle is the same size and shape. This process also helps reduce waste by allowing unused plastic to be recycled and used again.