At present, the two-color mold (double shot injection mold) is becoming more and more popular in the market. This process can make the appearance of the product more beautiful, and it is easy to change the color without spraying, but the cost is expensive, the technical requirements are high. There is also overmold that can meet each other. The quality products of the two molds are quite different. So what’s the difference between the two-color mold and overmold? Which one to choose? Blow is the relation to overmolding and double shot injection molding.

What Is Two-Color Injection Molding

Two-color mold or ‘two-shot’ injection moulding consists of processing two different polymers (or two different colors of one polymer) into an end product by means of one injection moulding process. This technology enables several functions to be integrated into an injection moulded product.

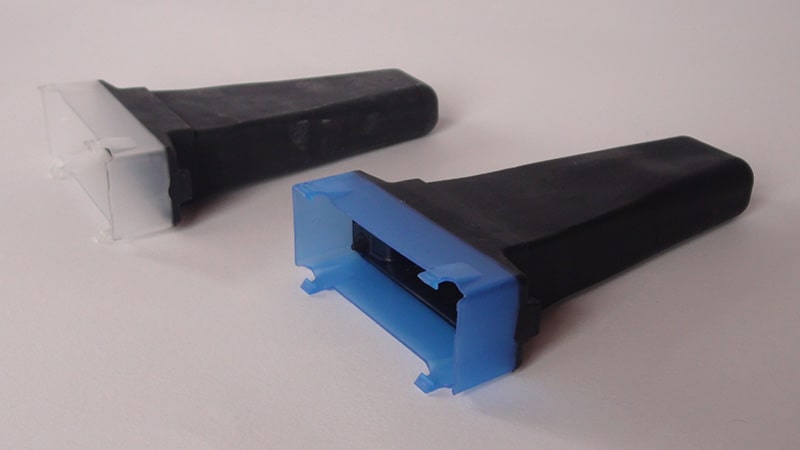

Two kinds of plastic materials are injection-molded on the same injection molding machine, and are divided into two molding, But the product only comes out of the mold once. Generally, this kind of molding process is also called double shot injection molding, which is usually completed by a set of molds and requires a special two-color injection molding machine. The process is relatively simple: one material is injected into a mold in order to make the initial piece of the product, followed by a second injection of another material that is compatible with the initial injection molded piece. The two plastic resins then form a molecular bond and the multi-resin molded part is cooled and ejected.

Advantages Of Two-Color Injection Molding

1. The two-color injection molded parts are not only increase friction, antiskid and elastic resin materials, making them more ergonomic and feel better.

2. The parts are strongly fitted and molded thus components or rather end products become more durable.

3. Two shot injection molding parts have high quality stability, easy to control, short molding cycle and high productivity. The production cost of two shot molded products can be less than 20%.

4. The appearance in terms of aesthetic value or beauty is high since many colours can be blended in the molding stages.

Two-Color Injection Mold Applications:

Product function requirements: power switch, mobile phone button

Improve hand feel: some hand-held products, such as electric tools, toothbrush handle, thermal cup

Increase the aesthetic feeling, such as the logo, which is beautiful and will not be rubbed off

What Is Overmolding (Over Mold)

Overmolding is an operation in which two or more mediums (substances) are merged to form an ending molded product, over-molding needs to make two separate molds, one is substrate (first mold), the second mold is called over mold, if the substrate is metal parts or brass parts, this type of overmolding we normally call insert molding, and insert molding only need one mold to finish the process. The over molding materials majorly used are thermoplastics and rubber. During overmolding, the activity that happens is either mechanical or chemical which leaves the two substances bonded.

Two kinds of plastic materials are injection-molded on different injection molding machine, and are divided into two molding. After taking out the mold from one set of mold, the product is then placed into another set of mold for overmolding. Therefore, the general molding process is usually completed by two sets of molds, without special two-color injection molding machine.

Advantages Of Overmolding

1. Compare to two shot injection molding, overmolding is more easy to make, you can use a normal injection molding machine to make 2 or 3 different colors in one molded part, or make two or three different materials in one ending part.

2. The plastic molding components are more reliable because there is no bonding at the manufacturing stage.

3. Reduced secondary operations; assembly and labor costs.

4. The parts have a high level of stability and constitution since after being left to mechanically inter-lock they become one.

What’s The Difference Between Overmold & Double Shot Mold, Which One To Choose?

The difficulty as like as double injection mold is to make two identical moulds. To achieve this result, the mold and equipment should be guaranteed. It needs to be higher than the mold in the processing and machining accuracy of the mold. When one of the parts needs to be modified, both back molds need to be modified at the same time.

However, this problem does not exist in the over mold. The over mold is to make a plastic part with color on the first monochrome injection molding machine, and then manually put this product into the second mold for molding. Because of manual placement, the accuracy is insufficient, which is easy to cause surface quality problems such as blister, strain and fracture after the product comes out, so the scrap quantity will be very large. Therefore, you can choose to use two-color injection mold to manufacture high-quality products, if you want to save costs and not too strict requirements for products, you can choose to use overmolding for production.

Are you looking for over molding or two shot injection molding service?

EX MOULD Co., Ltd is one of the best injection moulding manufacturers in China. Have more than 12 years of experiences providing plastic mold design & custom mold services. With high-quality mould and high-quality service, EX MOULD has won the trust of all customers. The company has excellent technical personnel team and advanced scientific and technological equipment to ensure that we design perfect plastic molds products for customers. We will offer you the most affordable price at high-quality plastic tooling and plastic injection molding parts for the long-term business relationship. We will also suggest you which is the best injection molding process for your products.