Nylon plastic injection molding is a vital procedure in international production. It produces long-lasting, lightweight, and flexible factors used in numerous industries. From car components to normal customer merchandise, nylon injection molding plays an important function in meeting present-day production dreams. Learn what nylon is, where Injection molded nylon components are used, and what have to you know about nylon plastic injection moulding.

What is Nylon?

Nylon is a kind of artificial polymer, furthermore known as polyamide, first added in the Thirties. It is well-known for its energy, flexibility, and resistance to vicinity on and tear. Nylon is broadly used rather for metal in hundreds of packages because of its exquisite universal performance and rate-effectiveness.

Nylon has specific houses that make it best for high-performance nylon polymers. It has an excessive melting point, and low friction, and can face up to exposure to chemical substances and abrasion. These abilities make nylon a sincerely perfect material for making unique and reliable additives.

Where is Nylon Plastic Injection Moulding Used?

Custom nylon injection molding services are applied in a sizable variety of industries. Its programs consist of:

- Car Industry: Nylon parts are utilized for motor parts, pinion wheels, and clasps because of the reality they’ll have the option to oppose extreme temperatures and deal with low erosion.

- Electronics: Nylon’s electrical protection homes make it top-notch for connectors, switches, and housings.

- Consumer Goods: Products like toothbrushes, sports devices, and kitchen utensils often function as nylon components due to their durability and mild-weight nature.

- Industrial Equipment: Nylon is carried out in conveyor belts, bearings, and pulleys for its sturdiness and potential to address pressure.

- Medical Devices: Nylon’s biocompatibility makes it a choice fabric for splendid clinical tools and gadgets.

These industries depend on applications of nylon injection molding for developing products that want to be precise, robust, and value-inexperienced.

What Other Advantages Does Nylon Plastic Injection Moulding Offer?

Nylon material properties for molding offer many advantages, making it a famous preference for producers. Here are a number of its key advantages:

- Strength and Durability: Nylon is difficult, impact-resistant, and can manage heavy loads without breaking.

- Heat Resistance: Its immoderate melting factor makes it appropriate for packages exposed to warm temperatures.

- Chemical Resistance: Nylon can face up to exposure to oils, solvents, and one-of-a-kind harsh chemicals, making it best for commercial and automobile elements.

- Low Friction: Its smooth ground and coffee friction make it notable for moving factors like gears and bearings.

- Lightweight: Nylon is plenty lighter than metallic, reducing product weight at the same time as preserving electricity.

- Design Flexibility: Nylon can be molded into complicated shapes with precision, permitting manufacturers to create intricate designs.

- Cost-Effective: Compared to metals and different materials, nylon gives exquisite universal performance at a decreased fee, mainly for massive production runs.

These benefits of nylon in injection molding are a green solution for generating outstanding factors.

Best Types of Plastic Injection Mold

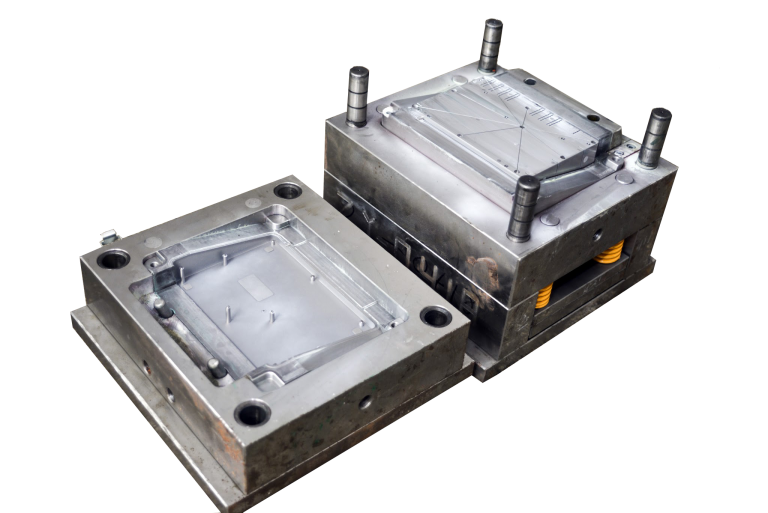

Plastic injection molds are important for generating a selection of merchandise with precision, performance, and sturdiness. Below are several best kinds of plastic injection molds for precise products:

Plastic Buckets Injection Mold

Plastic buckets are substantially applied in households, production, and business applications. The injection molds for buckets are designed for big, sturdy, and realistic designs. These molds make certain uniform thicknesses, easy edges, and durability. They allow for customization in duration, shape, or even the addition of organization logos or patterns. With excessive efficiency, the molds can produce buckets in bulk at the same time keeping regular pleasant.

Plastic Shoe Polishing Injection Mold

Shoe polish packing containers require precision molds to create compact and purposeful designs. These molds produce items like polish tins, squeeze bottles, and caps. The key attention is on reaching first-class sealing and ease of use. Plastic shoe polishing injection molds ensure the containers are mild-weight, long-lasting, and visually attractive. They are great for producers looking for mass manufacturing with accuracy and consistency.

Plastic Oil Caps Injection Mold

Oil caps are critical in vehicle and commercial programs, requiring a comfy form and leak-evidence design. Plastic oil caps injection molds are built to create immoderate-precision products with tight tolerances. These molds produce caps with threading or snap-fit designs, making sure of reliable standard performance in sealing packing containers. The materials used are often resistant to warm temperatures and chemical materials, consisting of their practicality.

Who is the Best Nylon Injection Molded Parts Wholesale in China?

If you’re looking for incredible nylon injection molded elements, EX MOULD CO. is the best choice in China. The agency has massive experience in nylon injection molding, mildew making, and designing custom additives. Their organization works carefully with customers to ensure the first-rate requirements of precision and performance.

EX MOULD CO. offers:

Custom Solutions: They talk about each consumer’s desires and offer tailored solutions for the nylon injection molding system.

Competitive Pricing: Their Nylon plastic manufacturing process is low cost, making them a rate-effective associate for companies.

Advanced Techniques: With rich enjoyment and cutting-edge generation, they deliver unique mildew production and inexperienced manufacturing.

Wide Range of Products: From small additives to massive, complicated designs, EX MOULD CO. can cope with any assignment.

In the End

Nylon plastic injection moulding is a versatile and green method for creating amazing factors utilized in diverse industries. Nylon’s energy, sturdiness, and flexibility make it an outstanding material for products that require precision and standard overall performance. If you’re considering nylon injection moulding, partnering with specialists like EX MOULD CO. guarantees you’ll accumulate top-notch results tailored to your desires.

With their enjoy, superior techniques, and energy of will to excellence, EX MOULD CO.is the ideal partner for your nylon injection moulding duties. Whether you’re inside the car, clinical, or customer gadgets location, nylon injection moulding offers a reliable manner for your manufacturing needs.

FAQs

What is the melting point of nylon used in injection moulding?

The melting element of nylon generally degrees between 220°C and 275°C, depending on the kind. This excessive melting difficulty makes it appropriate for heat-resistant programs.

Can nylon injection moulding create complicated shapes?

Yes, nylon injection moulding is best for producing difficult and specific designs. It allows producers to create complicated shapes efficiently.