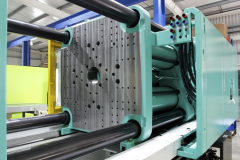

Injection moulding is a popular process used to make plastic products. It involves melting plastic and injecting it into a mould. The plastic cools and takes the shape of the mould. Many different plastics are used in injection moulding. Each type of plastic has unique properties that make it suitable for different applications. In this article, we will explore what plastic is used in injection moulding and why they are important.

What Is Injection Moulding?

Injection moulding is an assembling interaction used to deliver plastic parts. It is used to make numerous items, from toys to vehicle parts. The cycle includes a few stages:

- Dissolving the Plastic: Plastic pellets are warmed until they soften.

- Infusing the Dissolved Plastic: The softened plastic is infused into a form.

- Cooling the Plastic: The plastic cools and solidifies inside the shape.

- Eliminating the Part: The strong plastic part is taken out from the shape.

This interaction takes into account the development of numerous indistinguishable parts rapidly and productively.

Types of Plastics Used in Injection Moulding

Different kinds of plastics are used in Infusion shaping. Each type has its resources and weaknesses. Here are irrefutably the most ordinary plastics used in this cycle:

Polypropylene (PP)

Polypropylene is an adaptable plastic that is comprehensively used in Infusion shaping. It is known for its versatility, strength, and assurance from fabricated materials. PP is a significant part of the time used to make packaging, vehicle parts, and family things.

Properties of Polypropylene

- Lightweight: PP is lighter than various plastics, making it ideal for applications where weight is a concern.

- Solid: It is impenetrable to mileage, which makes it reliable.

- Compound Safe: PP doesn’t answer with various artificial materials, making it sensible for holders and various things that come into contact with artificial materials.

Acrylonitrile Butadiene Styrene (ABS)

ABS is one more famous plastic used in Injection shaping. It is known for its solidarity and effective opposition. ABS is ordinarily used to make toys, electronic lodgings, and auto parts.

Properties of ABS

- Solid and Extreme: ABS can endure effects and stress without breaking.

- Great Appearance: It has a smooth, sparkling surface that makes it outwardly engaging.

- Heat Safe: ABS can endure high temperatures, making it reasonable for items that need to get through the heat.

Polyethylene (PE)

Polyethylene is perhaps of the most generally involved plastic on the planet. It comes in various structures, including high-thickness polyethylene (HDPE) and low-thickness polyethylene (LDPE). PE is used to make jugs, packs, and compartments.

Properties of Polyethylene

- Flexible: PE can be used in various applications because of its adaptability.

- Water Safe: It doesn’t ingest water, making it ideal for compartments and bundling.

- Minimal expense: PE is economical, and settling on it is a savvy decision for some items.

Polyethylene Terephthalate (PET)

PET is regularly used to make jugs and compartments for drinks and food. It is known for its solidarity and straightforwardness.

Properties of PET

- Clear and Straightforward: PET is frequently used for items that should be transparent.

- Solid: It can hold fluids without breaking.

- Recyclable: PET is effectively recyclable, making it harmless to the ecosystem choice.

Polystyrene (PS)

Polystyrene is used to make various items, including dispensable cutlery, Albumcases, and bundling materials. It is known for its unbending nature and clearness.

Properties of Polystyrene

- Unbending and Solid: PS is hard and keeps its shape well.

- Clear: It is frequently used for items that should be straightforward.

- Lightweight: PS isn’t weighty, making it simple to deal with and transport.

Polyvinyl Chloride (PVC)

PVC is used in many applications, from lines to clinical gadgets. It is known for its sturdiness and protection from ecological elements.

Properties of PVC

- Tough: PVC can endure a ton of mileage.

- Climate Safe: It doesn’t corrupt effectively when exposed to daylight and downpours.

- Adaptable: PVC can be made both inflexible and adaptable, contingent upon the application.

Choosing the Right Plastic for Injection Moulding

Picking the right plastic for Injection shaping relies upon a few elements. Here are a few hints to assist you with pursuing the best decision:

Understand Your Needs

Ponder why you want the plastic. Do you want areas of strength for something tough? Or then again do you want something adaptable? Understanding your necessities will assist you with picking the right sort of plastic.

Consider the Cost

Various plastics have various expenses. Set a spending plan and search for choices inside that reach. Keep in mind, at times it merits paying a smidgen something else for better caliber.

Look at the Properties

Each sort of plastic has interesting properties. Take a gander at the properties of every plastic to see which one meets your necessities. Consider factors like strength, adaptability, and substance obstruction.

Consult with Experts

If you don’t know which plastic to pick, talk with specialists. They can give significant guidance and assist you with settling on the best choice.

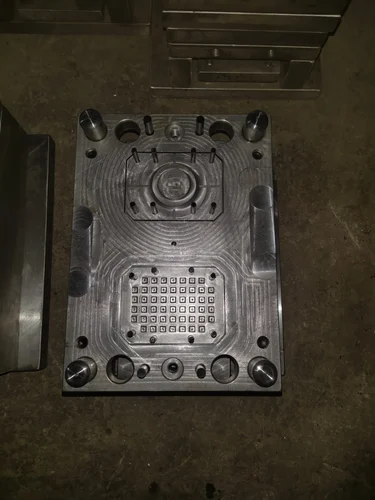

Where to buy the best injection moulding tool?

Assuming you’re searching for the best Injection shaping instruments, EX MOULD Co., LIMITED is the top decision. They give excellent Injection shaping devices that are solid and exact. EX MOULD Co. has a great many devices to suit various requirements, making them ideal for different businesses.

Purchasing from EX MOULD Co. is simple and helpful. You can visit their site to investigate their broad choice. Definite item depictions and pictures assist you with tracking down the ideal apparatus for your venture. Their costs are serious, guaranteeing you get astounding worth.

Besides, EX MOULD Co., LIMITED offers remarkable client assistance. Their proficient group is generally prepared to assist with any different kinds of feedback. They guarantee you have a smooth and fulfilling buying experience.

Final Thoughts

Injection moulding is an adaptable communication used to convey a considerable number of plastic things. Different types of plastics are used in this cycle, each with surprising properties that make them sensible for various applications. Understanding the properties of every sort of plastic can help you pick the right material for your necessities.