In this piece, we’ll cover all kinds of plastic that can be applied to that process. We will talk about plastics like ABS, which is shiny and strong. Polypropylene is chemically and light-inert and has zero reaction. Akin to a rubber strap, polyethylene can be strong and malleable. Polycarbonate is also as solid and clear as glass. Every plastic has unique features that render it suitable for specific uses. The tough ones might be used, for example, for creating helmets. Also, bottles that need simple tapping could be modified with elastic ones. This manual will be helpful for you if you’re curious or seeking to create cool stuff. You will know the unique features of each kind of plastic and why these are used in various goods. Let’s discuss plastic and its impact on the things we use daily!

What is injection molding?

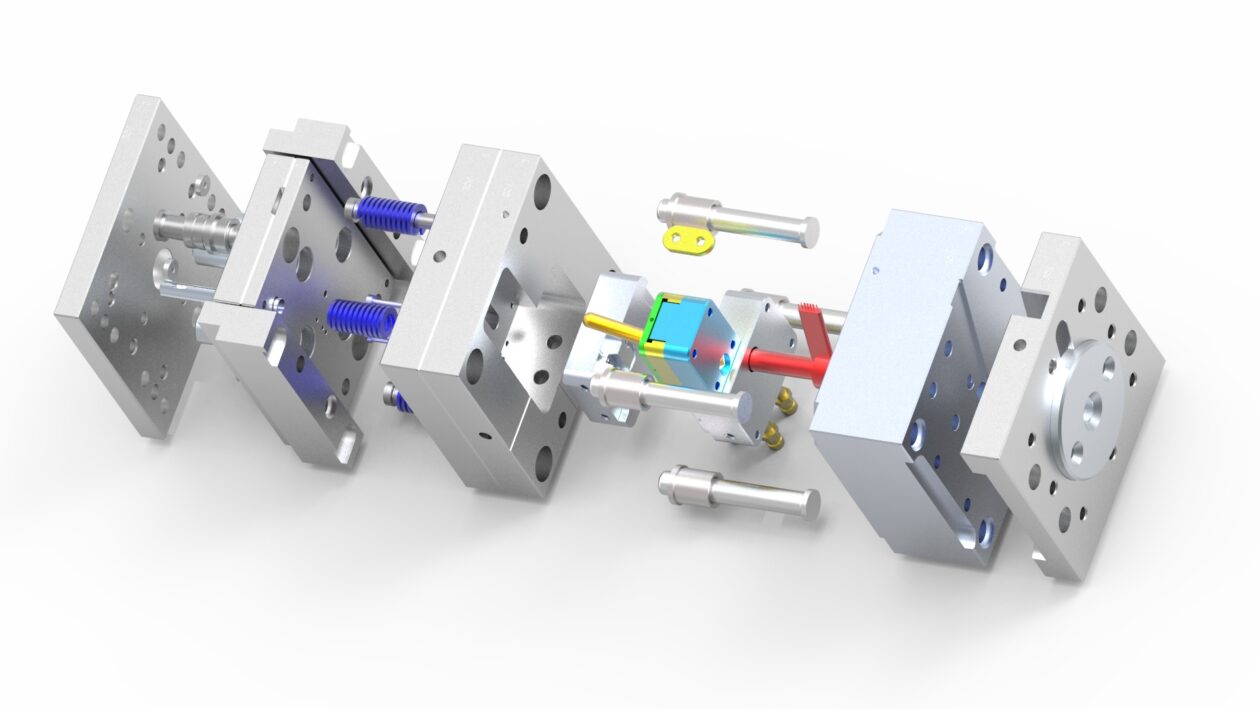

Making items using injection molding is genuinely excellent! Picture of putting sticky plastic into an exact mold. Next, let it be set up into the precise shape you need. That’s the basic process of injection molding. First, the plastic melts until it turns into a thick syrup. After that, it goes into a mold like a classy ice cube tray. The form of the item you plan to build, such as a toy or mobile case, is created on the mold. The plastic sets and takes on the form of an object after it cools. Many things we use daily are made with it, like toys, cups, and auto bits! It is a vital way of producing because it is quick, precise, and able to make a great deal of items quickly.

What plastic is used in injection molding?

- Polyethylene (PE): PE is a valuable and common polymer for its rigidity, agility, and pricing. It exists in various items, like bottles, pipes, and plastic bags.

- Polypropylene (PP): It is a solid, volatile material. With many other uses, it gets used in toys, parts for cars, and packaging.

- Polystyrene (PS): It’s stiff yet light. It can be found in packing, waste cutlery, and CD cases.

- Acrylonitrile butadiene styrene (ABS): It is strong enough to deal with force. And it can do it without breaking. Electronics, vehicle parts, and LEGO pieces are some of the products that include ABS.

- Polyvinyl Chloride (PVC): This strong product comes in soft and hard. It exists in pipes, surfaces, glazing, and wires, among other things.

- Polycarbonate (PC): This visible, strong plastic is used in safety eyewear. And it is used in parts of cars.

- Nylon, or polyamide: It is a sturdy material utilized in clothes, shafts, and gears.

- PET, or polyethylene terephthalate: It is simple, strong stuff. Meal boxes, drinks, and fabrics all carry it.

There are variants of these materials. Also, they are helpful for an array of everyday tasks.

Which is the most advanced place for injection molding?

Its main feature is the power of this method to make plenty of intricate plastic parts. This strategy is beneficial. With great clarity, building things from huge car parts to tiny toy parts is perfect. It’s great since it makes use of many plastic types. So, there is a plastic that must be highly elastic, firm, or heatproof! Are you curious about reading more about this, or do you need help with injection molding? Take a peek at EX MOULD Co., Ltd. They will help you with your tasks and have plenty of expertise. Find out what EX MOULD Co., Ltd. can do by browsing their web page!

FAQs

Which plastics work best for what?

ABS for toys, PVC for pipes, for example.

What makes plastic different?

Hardness, flexibility, and cost vary.

Can we use recycled plastics?

Yes, to reduce waste and help the environment.

How does plastic choice affect cost?

Some are pricier due to performance or uniqueness.

Are there any green concerns?

Think about recyclability and toxicity.

Can we mix stuff with plastic?

Yes, for colors, strength, and safety.

Are some plastics harmful to our health?

Check for chemicals and fumes.

What’s new in plastic technology?

Better materials for more vital, safer products.

Conclusion

In a nutshell, the plastic used for injection molding is vital. Start picking ones that are solid, flexible, or heat-proof from the many types that exist. You can use many common materials. You want the result to have and work like really crucial. It also depends on the price it incurs and if it hurts nature. Using the injection molding process and using the correct plastic is vital. We can use it to make an array of unique gifts that match it and look great!