Polyamide injection molding is a groundbreaking production technique. This system is widely used to create strong, durable parts for many industries. Because of its unique properties, polyamide is preferred for everything from automobiles to electronics. We’ll explain the nylon injection molding process , its benefits, and why it’s a game-changer for organizations.

What is Polyamide Injection Molding?

Polyamide injection molding is a method where polyamide, commonly called nylon, is melted and appropriately injected into a mold. This mold shapes the cloth into a popular product. Polyamide is a form of high-performance thermoplastics , which means it turns soft while heated and solidifies at the same time as cool. The approach starts with feeding polyamide pellets into a heated barrel.

The warmth melts the plastic, then injects it into a mold below excessive stress. The mold is opened once the material cools and solidifies, and the finished aspect is removed. This method is green, particular, and best for making complex parts in large quantities . Polyamide’s power, flexibility, and resistance to heat and chemicals make it best for injection molding. Products made using this technique are dependable and prolonged-lasting.

Benefits of Our Polyamide Injection Molding Service

Our polyamide injection molding provider offers many advantages.

First, we are conscious of handing over the best parts. Every product is made with precision to satisfy your particular requirements. Whether you want small parts or huge, complex components, our provider guarantees steady consequences.

Another gain is charge efficiency. Injection molding permits mass manufacturing with minimal waste. This reduces the industrial polymer manufacturing fee, making the price range pleasant for agencies.

Durability is likewise a key benefit, as is polyamide’s robust nature, which ensures its products can resist harsh conditions. This is especially important for the automotive industry, where parts must withstand excessive pressure.

Additionally, our issuer offers flexibility. Polyamide can be molded into complex shapes, providing endless design opportunities. From gears to casings, our method can handle everything. Lastly, we prioritize sustainability. Polyamide is recyclable, and our method minimizes material waste. With this technique, you get inexperienced merchandise without compromising quality.

Polyamide Plastic Molds and Polyamide molded parts.

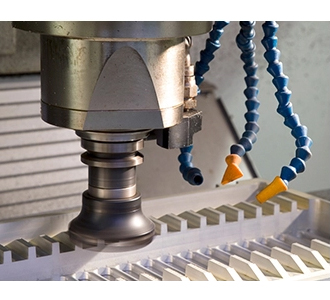

Polyamide molds are the tools used to shape molten polyamide into precise designs. These molds are generally made from hardened metallic or aluminum. They are designed with brilliant care to ensure accuracy and durability. Molded parts made out of polyamide are recognized for their excessive performance.

For example, polyamide is used in the car industry to make engine parts and fuel traces. These parts should take care of excessive temperatures and strain, which polyamide gives you. In electronics, polyamide molded components are used for connectors and casings. The fabric’s insulating homes make it perfect for the one’s applications.

Similarly, polyamide is discovered in products like kitchen utensils, sports activities, and sports devices in patron goods because of its electricity and lightweight nature. Polyamide-molded elements also are immune to chemical substances and abrasion. This makes them suitable for industrial applications, conveyor belts, and system components.

Polyamide Injection Molding Process Highlight

The polyamide injection molding procedure stands out for its performance and precision. Here is a step-by-step process of the technique:

Material Preparation

The way begins with the steering of polyamide injection molding materials, commonly within the shape of small pellets. These pellets are dried thoroughly to remove any moisture, as moisture can negatively affect the first-class and electricity of the final product.

Melting the Polyamide

The dried pellets are fed into the hopper of an injection molding system. From there, they circulate through a heated barrel, where they are melted. The temperature inside the barrel is cautiously managed to ensure the polyamide reaches the proper viscosity for molding.

Injection into the Mold

Once the polyamide is in the molten United States of America, it’s injected into a custom-designed mold hollow area. The mold is crafted to fit the favored form of the final product. High pressure pressures the molten polyamide into each mold corner, ensuring specific statistics and uniformity.

Cooling and Solidification

After the mold is filled, the cloth is permitted to relax. The cooling degree is crucial as it solidifies the polyamide into the exact form of the mold cavity. The cooling time can vary depending on the dimensions and complexity of the object.

Ejection of the Part

Once the polyamide has virtually solidified, the mildew opens, and the completed component is ejected. Ejector pins or distinctive mechanisms are frequently used to make sure the detail is removed without harm.

Post-processing (if needed)

Automotive plastic components might also require extra finishing steps, such as trimming more excellent fabric (flash) or using floor remedies like sprucing or painting. These steps ensure that the final product meets specs and aesthetic requirements.

Quality Control

Each element undergoes excellent management assessments to ensure it meets the desired standards. These assessments include reading dimensions, strength, and surface stop. Any faulty factors are recognized and discarded or recycled.

This way is incredibly automated, considering steady high-quality and excessive production velocity. Modern machines with advanced controls precisely control temperature, pressure, and timing, decreasing mistakes and improving overall performance. Polyamide’s precise homes, which include power, flexibility, and resistance to warmth and put on, make it an ideal fabric for injection molding.

The Best Polyamide Injection Molding Service in China

When it involves polyamide injection molding services in China, EX MOULD CO. can be the top choice. With years of expertise, present-day technology, and a determination to achieve high quality, EX MOULD has extraordinary consequences for various industries. Our modern facilities and superior gadgets ensure precision and overall performance in each undertaking. We create durable, extremely good polyamide molded components that meet the needs of automobile, electronics, and client items sectors.

EX MOULD is dedicated to customer satisfaction. Our professionals work carefully with clients to develop and implement custom plastic molding solutions that meet their requirements. We also prioritize sustainability, using green practices and materials wherever possible. Choosing the EX MOULD approach means partnering with a reliable carrier company that values excellence, innovation, and client success.