2024.3.1

Welcome to our detailed guide to blow molding. This guide will discuss the common types of blow molding processes. And one of the standard blow molding processes is injection blow molding. Injection blow molding may be considered some form of ‘magic.’ It is for the manufacture of plastic objects like bottles and containers. It is a very vital process for the plastics industry. This technique is popular since we can fabricate everything from it. Such processing flexibility makes it possible for users to develop everything using plastic. It is all why it’s a common approach for people to make hollow plastic items.

This process is used to make hollow plastic things. First, making plastic pellets into a liquid requires melting them. After that, this liquid turns into a parison, which is a hollow tube. A mold gets filled with parsley and blown away by the air. It leads to the plastic changing the mold’s design. The new plastic part is removed, and the mold opens once it has cooled. Car parts, bottles, and containers are created with this method. Making lots of similar parts quickly and correctly can be done with blow molding. Also, it’s simple to use when creating strong yet light goods. Blow molding is vital in many industries, like packaging and automobiles. Making many of the same parts at once makes it a common choice for mass manufacturing. Its adaptability to different materials and forms makes it useful in all situations. Blow molding has a few drawbacks despite its benefits. Still, current advances in technology are refining it. So, blow molding remains a vital part of the plastics sector.

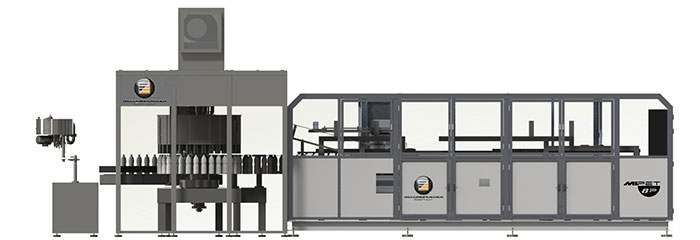

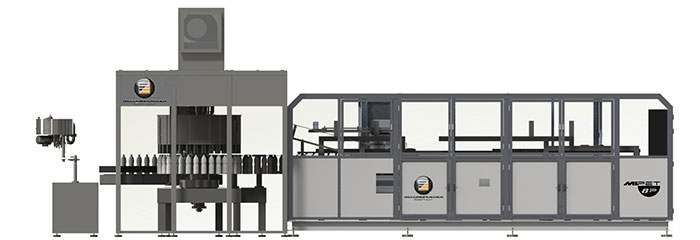

One standard process for making plastic items is Injection blow molding. It is like a magic trick that turns plastic into bottles and jars. First, we make a mini version of the bottle called a preform. It looks like a plastic tube with a unique top. Then, we heat it and blow air into it. It makes the plastic grow and fill a mold shaped like the final bottle. This process is unique because it makes perfect bottles every time. And it does it without wasting any plastic. It’s great for making all sorts of bottles, like for drinks, lotions, and medicines. Even though the machines for this are big and expensive, they help make lots of bottles quickly. It’s a fantastic way to make the containers we use every day! It offers an honest and sensible choice for a range of items. Many industries choose it for its ability to quickly and safely make the same parts in large numbers.

If you’re seeking a great place to make things with blow molding, EX MOULD Co., Ltd. is fantastic! They are good at making all sorts of plastic items. They work smartly to create stuff like bottles and containers. They use awesome machines and know a lot about producing high-quality products. To see what they can do, check out their EX MOULD Co., Ltd website. It’s a place where they show how they make things and how they can help with any project. It is a friendly website. So, if you need anything about blow molding, visit this site.

Usually, it can work with other materials, like certain types of glass.

It’s better for simple shapes. Complicated ones need a different way of molding.

Yes! It can use many kinds of plastic to make all sorts of items.

It can be if we recycle the items we make and are smart about using materials.

This way is better for making smaller, more detailed items quickly. And this way is more effective and better than other ways.

The most common way to make plastic things like bottles is injection blow molding. It’s a unique method where they blow air into hot plastic to shape it. People like using it because it can make lots of different things. It creates everything from the small bottles we use daily to big barrels. It’s a process that shows how creative and valuable making things with plastic can be! And it is the most advanced and standard blow molding process in the world of plastics.