Injection molding is a popular manufacturing process. It involves injecting molten plastic into a mold to create various shapes and products. But have you ever wondered what kind of plastic is most commonly used in this process? Let’s find out the most common injection molded plastic!

Understanding Injection Molding

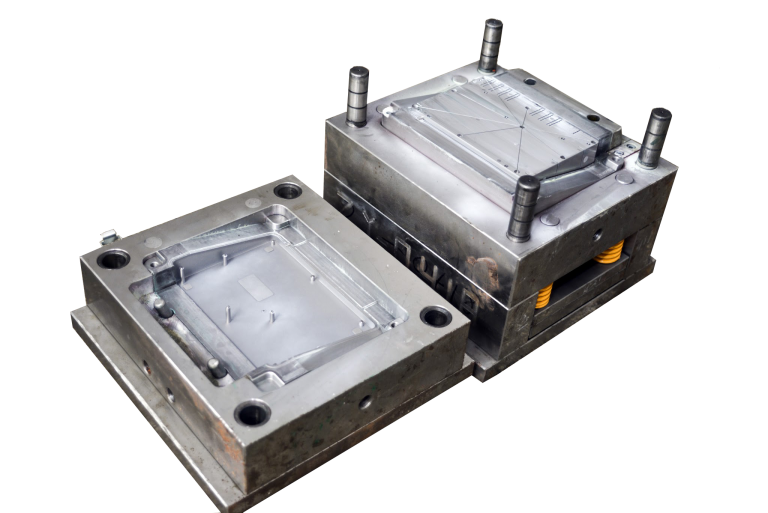

Before we investigate the most widely recognized plastic, we should comprehend injection molding a piece better. This strategy is used to deliver numerous things we use consistently. These things incorporate toys, vehicle parts, and, surprisingly, clinical gadgets. The interaction includes warming plastic until it becomes fluid. Then, at that point, the fluid plastic is infused into a mold. When it chills off, it solidifies into the state of the form.

Why Choose Injection Molding?

Injection molding is well known because of multiple factors. In the first place, it can create enormous amounts of items rapidly. Second, the things made are exceptionally precise and can have complex molds. In conclusion, it diminishes squander since the abundance of plastic can be reused and used once more.

Types of Plastics Used in Injection Molding

Many types of plastics are used in injection molding. Some of the common ones include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyvinyl Chloride (PVC)

The Most Common Injection Molded Plastic: Polypropylene (PP)

Polypropylene, or PP for short, is the most common plastic used in Injection molding. We should become familiar with this adaptable material.

What is Polypropylene?

Polypropylene is a kind of plastic produced using the polymerization of propylene gas. It was first polymerized in 1951 and has since become extremely well known. It is a thermoplastic, and that implies it turns out to be delicate when warmed and hard when cooled. This property makes it ideal for Injection molding.

Why is Polypropylene So Popular?

There are a few justifications for why polypropylene is the top decision for Injection molding:

- Flexibility: PP can be used for a large number of items. These incorporate packaging, car parts, family things, and clinical gadgets.

- Strength: It is impervious to weakness, and that implies it tends to be bowed and flexed without breaking.

- Compound Opposition: PP is impervious to numerous synthetic substances, making it appropriate for compartments and lines.

- Minimal expense: It is less expensive compared with different plastics, making it efficient for large-scale manufacturing.

- Lightweight: PP is lighter than numerous different plastics, which is helpful in enterprises like cars where it is critical to diminish weight.

Common Uses of Polypropylene

Presently, how about we investigate a few normal items produced using polypropylene:

- Packaging: PP is broadly used in packaging. You can find it in food holders, bottle covers, and, surprisingly, in the film used to wrap items.

- Auto Parts: Numerous vehicle parts are produced using PP. These incorporate guards, dashboards, and other inside parts.

- Family Things: PP is used in making different family things like capacity boxes, furniture, and toys.

- Clinical Gadgets: In the clinical field, PP is used to make needles, pill compartments, and, surprisingly, clinical inserts.

- Materials: PP is used to make strands for floor coverings, ropes, and even dresses.

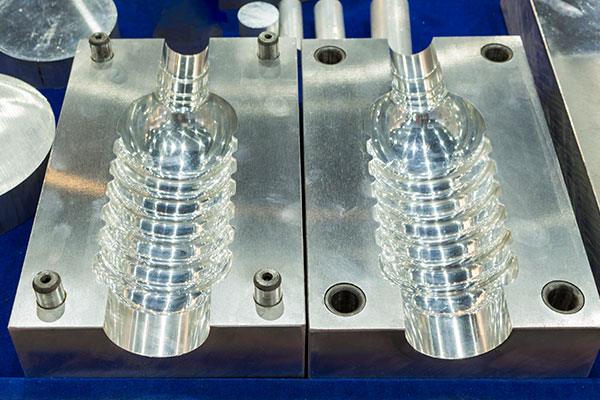

How is Polypropylene Processed in Injection Molding?

Handling polypropylene in Injection molding includes a few stages:

- Warming: PP pellets are warmed until they liquefy.

- Injection: The liquid PP is infused into a mold.

- Cooling: The form is cooled so the PP can solidify into the ideal mold.

- Launch: The solidified plastic is catapulted from the mold.

- Managing: Any abundance plastic is cut back.

Benefits of using Polypropylene

Involving polypropylene in Injection molding has many advantages:

Savvy: PP is reasonable, which keeps creation costs low.

High Efficiency: The Injection molding interaction is quick, considering high creation rates.

Quality: Items produced using PP are excellent, with exact aspects and smooth completions.

Recyclable: PP is recyclable, which means it a harmless to the ecosystem decision.

Challenges with Polypropylene

While PP is an extraordinary material, it has a few difficulties:

Temperature Responsiveness: PP can become fragile at exceptionally low temperatures.

UV Debasement: It can corrupt when presented with UV light for significant stretches.

Combustibility: PP is combustible and can be consumed whenever presented to a fire.

Despite these difficulties, the advantages of PP make it the most widely recognized plastic used in Injection molding.

Comparing Polypropylene with Other Plastics

We should contrast PP and a few other regularly used plastics:

- Polyethylene (PE): PE is likewise generally used yet isn’t quite a major area of strength for so strong as PP. It is frequently used for plastic sacks and containers.

- Polystyrene (PS): PS is fragile and can break without any problem. It is used for dispensable things like cutlery and bundling peanuts.

- Acrylonitrile Butadiene Styrene (ABS): ABS is solid and intense however more costly than PP. It is used for things like LEGO blocks and electronic lodgings.

- Polyvinyl Chloride (PVC): PVC is used for lines and links however is heavier and less adaptable than PP.

Final Words

Polypropylene is the most common plastic used in Injection molding for good reasons. Its flexibility, strength, and cost-viability make it ideal for a large number of items. While it has a few difficulties, progressing developments are making PP far superior. As innovation progresses, we can hope to see significantly more purposes for this astounding material.