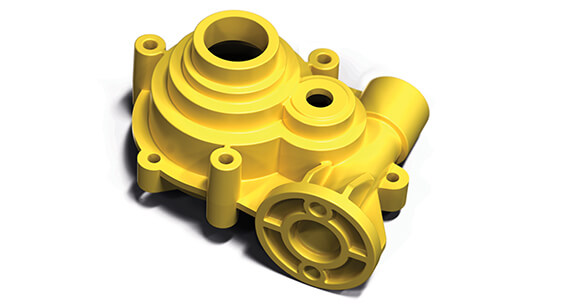

The shape accuracy of injection molded parts should meet the strict dimensional tolerance, geometric tolerance and surface roughness. In order to carry out precision injection molding, there must be many related conditions, and the most essential factors are injection mold design, injection molding process and general production. Read on the article and get to know more details.

How To Control The Dimensions Of Injection Mold Products?

Mold Design Control

● First of all, we need to fully understand the technical requirements for the mold structure, material, hardness, precision, etc., including whether the shrinkage rate of the plastic material is correct, whether the 3D size modeling of the product is complete, and reasonable processing and analysis.

● The appearance of the injection molding products such as shrinkage cavity, flow mark, dip angle, weld line and crack should be fully considered.

● On the premise of not hindering the product function and pattern formation of injection molded parts, the processing method of mold should be simplified as far as possible.

● Whether the parting surface is suitable or not, the die processing, forming appearance and deburring of formed parts should be carefully selected.

● Whether the pushing method is appropriate, whether the push rod, discharge plate, pushing sleeve and other methods are adopted, and whether the position of the push rod and discharge plate is appropriate.

● Whether the side core pulling mechanism is suitable, the action is flexible and reliable, and there should be no jamming.

● What kind of temperature control method is more suitable for plastic products, which structure is used for temperature control oil, temperature control water and coolant, and whether the size, number and location of coolant holes are appropriate.

● The gate form, the size of the material channel and the feeding gate, and whether the gate location and size are appropriate.

● The effect of heat treatment deformation of various modules and die cores and the selection of standard parts are appropriate.

● Whether the injection quantity, injection pressure and clamping force of injection molding machine are sufficient, whether the nozzle R and gate sleeve aperture match properly.

Injection Molding Manufacturing Process Control

Although it has been fully considered and arranged in the design stage, there will be many problems and difficulties in the actual production. We should try our best to meet the original intention of the design in the production, and find out the more effective, more economic and reasonable process means in the actual processing.

1. Choose economical and suitable machine tools and make 2D and 3D processing plans.

2. It can also consider appropriate fixture for auxiliary preparation in production, rational use of cutting tools, prevent deformation of product parts, prevent fluctuation of shrinkage rate of product parts, prevent demoulding deformation of product parts, improve the accuracy of mold manufacturing, reduce errors, prevent changes in mold accuracy, etc., a series of production process requirements and solutions.

3. Here are the reasons for the dimensional error and the corresponding proportion, drafted by the British Plastics Federation (BPF):

– Mould manufacturing tolerance is about 1 / 3.

– Tolerance caused by mold tear is 1 / 6.

– The error caused by the uneven shrinkage rate of the molded part is about 1 / 3.

– the error caused by the difference between the preset shrinkage rate and the actual shrinkage rate is about 1 / 6.

Therefore, it can be seen that the manufacturing tolerance of the mold should be less than 1 / 3 of the dimensional tolerance of the molded part, otherwise it is difficult for the mold to ensure the geometric dimension of the formed part.

Injection Molding Production Control

It is a common problem that the geometric dimension of plastic parts fluctuates after injection molding.

1.Control of material temperature and mold temperature

The control of material temperature and mold temperature requires different temperature requirements for different grades of plastics. The poor fluidity of plastic materials and the use of more than two kinds of mixtures will have different situations. The plastic materials should be controlled within the optimal flow value range, which is usually easy to achieve, but the control of mold temperature is more complex. Different geometry, size and wall thickness ratio of the molded parts have certain requirements for the cooling system, and the mold temperature controls the cooling time to a great extent.

Therefore, the mold should be kept at the allowable low temperature as far as possible, so as to shorten the injection cycle and improve the production efficiency. If the mold temperature changes, the shrinkage rate will also change. If the mold temperature remains stable, the dimensional accuracy will be stable, so as to prevent the deformation, poor gloss, cooling spots and other defects of the molded parts, and make the physical properties of the plastic in the best state.

2. Adjustment And Control Of Pressure And Exhaust

The proper injection pressure and the matching of clamping force should be determined when the mold is debugged. The air in the gap between the mold cavity and the core and the gas generated by the plastic must be discharged from the exhaust groove. If the exhaust is not smooth, there will be insufficient filling, weld lines or burns.

These three kinds of forming defects sometimes appear in the same part occasionally. If there is a thick wall around the thin-wall part of the shape part, the shrinkage mark will appear when the mold temperature is too low, and the burn phenomenon will occur when the mold temperature is too high. Usually, weld marks will appear at the burned part at the same time, and the exhaust groove is often ignored, which is generally in a small state. Therefore, as long as there is no burr, the depth of the exhaust shoulder should be as deep as possible, and a large ventilation groove should be set at the back of the shoulder, so that the gas passing through the shoulder can be quickly discharged out of the mold.

3. Compensation control of injection molding part dimension

Due to the different shape and size of some plastic parts, with the change of temperature and pressure loss after demoulding, deformation and warpage will occur in different situations. At this time, some auxiliary fixtures can be adjusted, and remedial measures can be taken promptly after the molded parts are taken out of the mold. Good correction and adjustment effect can be achieved after the natural cooling and setting. If strict management is ensured in the whole injection molding process, the size of injection molded parts will be very ideal control.

Summary

Under the combined action of these, different plastics have different polymer morphology and rheological properties. All factors affecting the above will affect the physical and mechanical properties, size & dimension, shape, precision and appearance quality of plastic products. In this way, the internal relationship between process factors and polymer properties, structural morphology and plastic products will be shown through plastic products. High pressure or ultra-high pressure injection and high-speed injection are often used to obtain small molding shrinkag.