2024.12.18

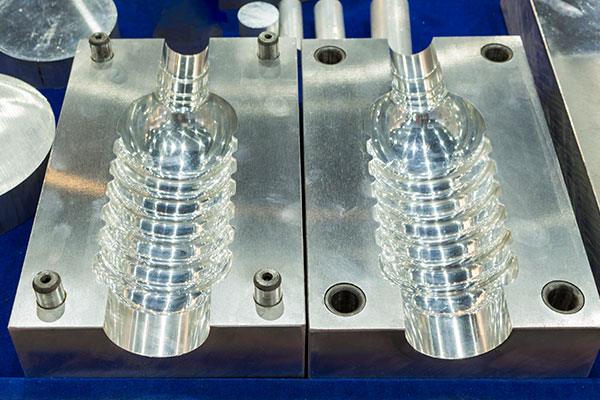

Injection molding is one of the most versatile and widely used manufacturing processes for producing plastic components. However, choosing the right plastic material is critical to achieving optimal performance, cost-efficiency, and durability. With a vast array of plastics available, each suited to specific applications, it’s essential to understand the properties, advantages, and limitations of different options.

In this blog, we’ll explore some of the most common plastic materials used in injection molding and how to choose the best one for your project.

Before diving into specific materials, let’s look at the primary factors to consider when selecting the ideal plastic:

ABS is a popular choice for injection molding due to its excellent balance of strength, impact resistance, and affordability. It is commonly used for consumer goods, automotive parts, and electronic housings.

Polypropylene is lightweight, flexible, and resistant to many chemicals, making it ideal for packaging, medical devices, and automotive components.

Polycarbonate is known for its exceptional impact resistance and transparency, making it suitable for safety equipment, lighting fixtures, and lenses.

Polyethylene, available in various densities (LDPE, HDPE), is valued for its flexibility, chemical resistance, and affordability.

Nylon is widely used for its strength, toughness, and resistance to wear, making it ideal for gears, bearings, and industrial components.

Polystyrene is a low-cost material often used for disposable items, toys, and packaging.

TPE offers the flexibility of rubber and the processability of thermoplastics, making it suitable for soft-touch components, grips, and seals.

The “best” plastic for injection molding depends entirely on the specific requirements of your project. Here’s how you can narrow it down:

Selecting the right plastic for injection molding is a critical decision that impacts the success of your project. Whether you need the durability of nylon, the transparency of polycarbonate, or the chemical resistance of polypropylene, understanding the strengths and limitations of each material is essential.

By carefully evaluating the application’s needs and consulting with material experts or injection molding professionals, you can ensure a cost-effective, high-performance solution tailored to your specific requirements.

Injection molding offers unmatched versatility, and with the right material, your product can achieve optimal functionality, aesthetics, and longevity.

Plastic Injection Mold Material Guide – Advantages & Applications Of 20 Common Injection Molding Materials

Plastic Injection Mold Material Guide – Advantages & Applications Of 20 Common Injection Molding Materials  10 Plastic Injection Processes – Advantages, Disadvantages, And Applications Of Plastic Injection

10 Plastic Injection Processes – Advantages, Disadvantages, And Applications Of Plastic Injection  Plastic Injection Mold vs. Other Molding Techniques: Which is Best

Plastic Injection Mold vs. Other Molding Techniques: Which is Best  Injection Molding Machines – Types, Costs, How To Choose The Best Machine For Plastic Injection Mold Manufacturing

Injection Molding Machines – Types, Costs, How To Choose The Best Machine For Plastic Injection Mold Manufacturing