Plastic injection molding is a way to make plastic things. First, the plastic is heated and melts like water. Then, the melted plastic is pushed into a mold. The mold shapes the plastic into anything you want. After it cools, it hardens and keeps its shape. This process is fast and can make a lot of things at once, like toys or bottles.

Key Steps in the Plastic Injection Molding

Plastic injection-molding is a simple way to make plastic parts. First, plastic is small and hard. It is put into a machine called the injection molding machine. The machine heats the plastic until it melts. Then, the melted plastic is pushed into a mold. The mold gives the plastic its shape. After that, the plastic cools. The part comes out. The mold is closed again, and the process starts over. The machine can make many parts quickly. Each part looks the same.

How Plastic Injection Molding Can Be Used for Mass Production of Parts

Injection molding is great for making lots of parts. After the mould is made, the machine can use it again and again. This means the machine can make thousands of parts without stopping. All the parts will be the same. The process is fast. It saves time and money. Plastic molding is suitable for making large numbers of parts, like toys, bottles, or car parts. The more parts you make, the cheaper each part gets.

How Does Plastic Injection Molding Ensure Consistency?

Injection molding makes parts that are all the same. The machine is exact. It ensures that the right amount of plastic is used each time. The mold stays the same, so each part looks the same. The plastic is always heated the same way. The mold shapes the plastic the same way. This makes sure all parts are the same size and shape. Whether you make one part or a thousand, they will all be the same. This is very important for products like toys, car parts, or medicine.

Best Plastic Materials for Injection Molding

There are many kinds of plastic for injection molding. Some are strong, some are light. ABS is strong and easy to mould. It is used to make toys and car parts. Polypropylene (PP) is light and can bend. It is used for containers and car parts. Nylon is robust and can handle heat. It is used for gears and parts that last a long time. Polycarbonate (PC) is clear and strict. It is used for glasses and phone parts. The best plastic depends on the part you need to make. Each plastic has different strengths.

Optimize the Plastic Injection Molding Process for Efficiency

To make injection molding faster and better, we can do a few things. First, we can make the mold better. A better mold means faster parts. We also want to use the right amount of plastic. This helps save material. Keep the injection molding machine clean and well-maintained. If the machine breaks or gets dirty, it can slow down. By doing these things, we can make parts faster and cheaper.

Get the Best Service for Plastic Injection-Molding

For good plastic molding services, check out Ex Mould Co., Ltd. They are experts in making injection molds. They can help you design and make parts for many things. They work fast and make sure the parts are high quality. To learn more, visit their website at Ex Mould Co., Ltd.

Different Applications of Plastic Injection-Molding

Injection molding is used everywhere! In cars, it makes parts like bumpers and dashboards. In medicine, it makes things like syringes and pill bottles. In toys, it makes parts for action figures and dolls. It’s also used to make parts for phones and computers. Because it’s fast and can make many parts, injection molding is used in almost every industry.

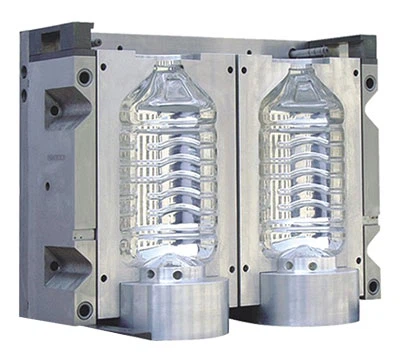

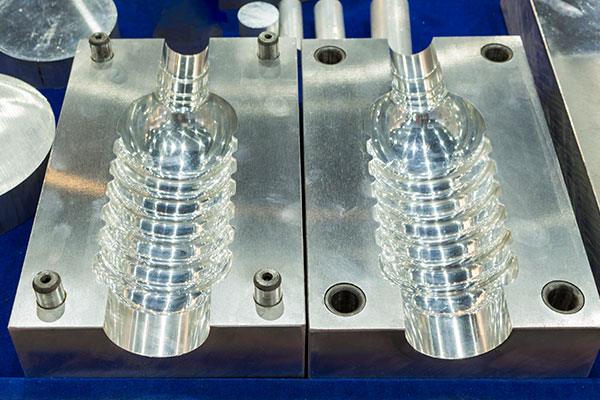

Does the Complexity of a Mold Affect the Injection Molding?

The mold makes the part. Simple molds are quick and cheap to make. But if you need a part with details, you need a more complex mold. Complex molds take longer to make and cost more. But they can make parts with more details. The more complicated the mold, the longer the process takes. But it’s worth it for parts with more features. Simple moulds make simple parts, but complex moulds make detailed parts.

Understanding these steps helps you see how plastic molding works. It’s a quick and easy way to make many parts. Whether you need a toy or a car part, injection molding can help. By picking the right plastic, making a suitable mould, and keeping the machine running well, you can make significant parts quickly.

It is a quick way to make things. The plastic melts and then cools in a mold. It can be used to make toys, bottles, and more. This method is fast and makes lots of things at once. It helps make many items we use every day.