Making mold tools is a critical step in the manufacturing process. It entails making precise tools that are used in a variety of industries, including the automotive, aerospace, and consumer products industries. We will go into great detail about mould tool manufacture in this blog post, including its definition, method, benefits, and uses.

What is Mould Tool Making?

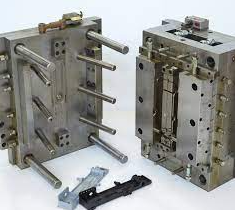

Making mold tools is the process of creating tools with exact shapes and dimensions that are used to make plastic or metal components. These devices, also referred to as moulds, are essential for mass manufacturing in fields that need precise and consistent parts.

The Process of Mould Tool Making

Design: Making a thorough design is the first step in the creation of a molding tool. This entails creating a 3D model of the desired component and the associated mold using computer-aided design (CAD) software.

Material Selection: The right material for the mold is selected after the design is finished. This stage involves taking into account elements like the necessary durability, temperature resistance, and compatibility with the production process.

Machining: During the machining stage, the mould is shaped using sophisticated equipment like CNC milling machines or lathes in accordance with the design. Precision and accuracy are ensured in the final result thanks to this process.

Heat Treatment: Some molds go through heat treatment procedures to increase their durability and hardness. This stage entails carefully regulating the heating and cooling cycles that are applied to the mold.

Surface Finishing: The surface of the mold is polished and completed after machining and heat treatment to ensure smoothness and lower friction throughout the manufacturing process.

Testing and Validation: To make sure the finished mould satisfies the necessary requirements, it is put through rigorous testing. This involves looking at things like functionality, durability, and dimensional precision.

Benefits of Mould Tool Making

Precision and Accuracy: Making mold tools enables the fabrication of components with a high degree of accuracy and precision, guaranteeing a constant level of quality throughout the manufacturing process.

Cost Efficiency: Making an investment in the creation of molding tools can result in long-term cost savings because mass-producing components lower production costs per unit.

Faster Production: Manufacturers can enhance efficiency and speed up turnaround times by employing moulds to optimize their production processes.

Applications of Mould Tool Making

Mould tool making finds application in various industries, including:

Automotive: Automobile elements including bumpers, dashboards, and interior trimmings must be produced using molds.

Aerospace: Wings, fuselages, and engine sections can only be produced using airplane components, which is why molds are so important.

Consumer Goods: A vast variety of consumer goods, including toys, appliances, and packaging materials, are made using mold tools.

FAQs

Q: What materials are commonly used for mould tool making?

A: Common materials include steel, aluminum, and various alloys based on the specific requirements of the mould.

Q: How long does the mould tool making process typically take?

A: The duration depends on the complexity of the mould, but it can range from several days to several weeks.

Q: Can moulds be reused?

A: Yes, moulds can be reused multiple times, depending on their design and durability. Proper maintenance and care can extend their lifespan and enable cost-effective production.

Q: Are there any limitations to mould tool making?

A: Mould tool making is a highly versatile process, but it does have limitations. Complex designs or intricate shapes may require specialized moulding techniques, which can increase the complexity and cost of the process.

Q: How can I ensure the quality of mould tool making?

A: To ensure quality, it is essential to work with experienced toolmakers who have expertise in mould tool making. Regular inspections, testing, and adherence to industry standards can further enhance the quality of the moulds.

Conclusion

Making mold tools is a crucial step in contemporary production. It makes it possible to create accurate, high-quality components that are used in numerous sectors. Manufacturers may optimize their production processes, cut costs, and provide excellent goods by understanding the mould tool producing process, its advantages, and its uses.

In this blog post, we looked at the complex processes involved in creating mould tools, from the original design stage to the validation stage. We talked about the benefits it provides, like accuracy, cost-effectiveness, and quicker production. We also emphasized its uses in the consumer products, aerospace, and automobile industries.

This thorough tutorial has given you insightful information, whether you’re a manufacturer trying to simplify your production or an enthusiast inquisitive about the world of mould tool building. Embrace the power of producing mould tools to open up a world of manufacturing opportunities.

Always keep in mind that creating high-quality mould tools starts with qualified personnel and cutting-edge machinery. Spend your money wisely, give precision first priority, and watch your production process flourish.

Now that you have a firm understanding of the process of generating mould tools, investigate the limitless opportunities it presents for producing accurate components of the highest caliber.