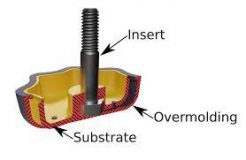

What is Insert Molding? Insert molding is a manufacturing process that uses a mold to create a part from a single piece of material. The insert molding process is often used to create plastic parts, but it can also be used to create metal parts.

What is Insert Molding– how to create a perfect insert molding job, and some of the common pitfalls to avoid:

When it comes to creating perfect insert molding jobs, there are a few key techniques that must be followed. First, it is important to create a detailed design of the insert molding that you wish to create. This will help to ensure that the insert molding is accurate in size and shape and that any seams or corners are properly formed. Next, it is important to create a full-size, accurate model of the insert molding in wax or clay.

This will help to ensure that the insert molding is correctly placed in the mold and that any cavities or protrusions are properly filled. Finally, it is important to use the correct molding compound and heat settings in the molding machine to ensure a perfect result. By following these simple tips, anyone can create perfect insert molding jobs.

Click here to read Part 1

What is Insert molding? Best 5 Tips:

The best way to get the most out of your insert molding tools and equipment is to take the time to learn how to properly use them. Here are a few tips to help get you started:

- Follow the manufacturer’s specifications for the tool you’re using. If you’re not using the manufacturer’s recommended tool, you may not get the best results.

- Keep your insert molding tools and equipment clean. Mold and dust can build up over time, which can negatively impact your tool’s performance.

- Be sure to adjust your insert molding tools and equipment to the right height and width. Improperly adjusted tools can cause problems with the molding process.

- Use a light touch when molding. Too much pressure can damage your insert molding tools and equipment.

- Make sure your insert molding tools and equipment are properly aligned before starting the molding process. Incorrect alignment can cause problems.

Insert molding tutorials – step-by-step guides on how to create a variety of insert molding projects, from simple to complex:

In today’s world, it is more important than ever to be able to create beautiful and intricate pieces of furniture. One way to achieve this is through the use of insert molding. Insert molding is a type of molding that is inserted into a piece of furniture to give it a more intricate and detailed look. There are a number of different tutorials that can help you learn how to create insert molding projects. In this article, we will provide a step-by-step guide on how to create a simple insert molding project. Before getting started, you will need the following supplies: -Insert molding -Plywood -Tape measure -Circular saw -High-grit sandpaper -Ruler or a straight edge -Cordless drill -1 inch hole saw 1-inch hole saw bit -Paint or a sealant 1. Begin by cutting the

Creative ideas for inserting molded parts into your designs, from simple shapes to more complex designs:

In the world of 3D printing, there are endless possibilities when it comes to creating intricate designs. But even if you’re not a 3D printing guru, there are still a number of ways to insert molded parts into your designs. Here are seven creative ideas for inserting molded parts into your designs: 1. use simple, geometric shapes to add visual interest to your designs; 2. create 3D models of objects and use them as a basis for inserting molded parts; 3. use recycled or upcycled materials to create interesting and unique designs; 4. experiment with different colors and patterns to create a unique look; 5. use laser cutting or 3D printing to create intricate details and patterns; 6. create sculptures or objects out of flexible materials; 7. use 3D printing to create functional objects, such as prosthetic limbs or glasses.

Insert molding projects – some of

your favorite I love molding projects because they are so versatile. I have a few favorite molding projects that I enjoy working on. One of my favorite projects is to create a mosaic wall using different types of tiles. I also really enjoy creating custom molding for cabinets and other furniture.

What is the conclusion of insertion molding:

The use of insert molding can improve the aesthetics of a product by adding new features or altering the shape of an existing part. It is a versatile manufacturing process that allows for the quick and easy production of custom products.

This is just a partial overview of insert molding and over molding. Are they the right solutions for you? Not sure how to apply them to your next project? Just contact our technical experts and we can offer helpful advice about how to get the best results from both processes.

10 Plastic Injection Processes – Advantages, Disadvantages, And Applications Of Plastic Injection

10 Plastic Injection Processes – Advantages, Disadvantages, And Applications Of Plastic Injection  Plastic Injection Mold Material Guide – Advantages & Applications Of 20 Common Injection Molding Materials

Plastic Injection Mold Material Guide – Advantages & Applications Of 20 Common Injection Molding Materials  What is Insert Molding – How it works: Part 1

What is Insert Molding – How it works: Part 1  Blow Molding Vs Injection Molding – What’s The Difference Between Blow Molding & Injection Molding

Blow Molding Vs Injection Molding – What’s The Difference Between Blow Molding & Injection Molding