Extrusion Blow Molding (EBM) makes plastic bottles and containers. It’s a simple procedure. The plastic will melt more easily if it is heated first. The plastic melts and forms into a tube. After that, the air is released into the tube. The tube expands to assume the shape of a bottle after air is injected into it. When plastic cools, it solidifies. Everything is set up to suit the container. This is simple and easy to do. EBM is used by several businesses that work with plastics . EBM facilitates cost and time savings. Jars, bottles, and other storage containers are among its often-used applications.

What is Extrusion Blow Molding, and How Does it Work?

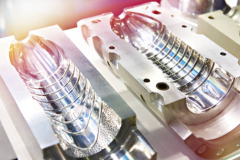

Do you want to know what is a blow mold (EBM) is? Using EBM is one method for creating things made of inert plastic. First, heat the plastic. The plastic becomes a tube as it cools. This is the proper name for that newly tube. As air is injected into the tube, its diameter increases. Plastic takes on a form as it fills a mold. Plastic solidifies as it cools. The formed shape, ready to be removed from the mold, may look like a bottle or container.

Differences of Extrusion Blow Molding & Injection Molding

Think about blow molding as an alternative. During the injection blow molding process, plastic is poured into a mold. It is for creating rigid pieces. Some of these elements are authentic. Forming the plastic into a tube is the first stage of extrusion molding. When air is pumped into it, it empties like a bottle. EBM might be used to create hollow objects. However, injection blow molding is designated for large objects only.

The Key Steps in Extrusion Blow Molding

Just follow these few lines of advice. Heating the plastic is the first step. Next, the plastic will be shaped into a tube. The tube is then made larger by forcing air into it. The mold is penetrated by this substance. The plastic takes on its own form after the mold is closed. The plastic solidifies as it cools. When the finished product opens, it comes out of the mold. Creating distinctive shapes is achievable with custom blow molding.

Products Are Made Using Extrusion Molding

Many different things rely on EBM. This process makes plastic bottles containing liquids like milk and water. It contributed to the creation of impossibly large items. Large containers and gasoline tanks may also be produced using machine blow molding. Stretch blow molding is used to make toys and filthy bottle cleaners, among other items. Because they are hollow within, they are easy to use and transport.

The Site you should visit for the best Blow Molding

Where blow molding is done will depend on your specific requirements. With custom blow molding, a wide variety of shapes may be created. For small bottles, injecting blow molding works well. Extrusion molding produces enormous cases. To make bottles or cups, it cuts the plastic. Blow shaping by machine blow molding is rapid and simple. EBM blow molding is the method used to create hollow objects. Bottles that are stretch blow molding are robust. For cocktails, this is useful. There are several types of molding used to create shapes. Ex Mold Co., Ltd. is a company you need to work with. They have perfect tools and expertise. They consistently provide top-notch goods. Their website is simple to use. Kindly stop by and explore the space.

Why is Extrusion Blow Molding vital in Making Plastic?

It is significant because it gives items a bold, light appearance. This method makes it simple to produce a wide variety of things. Because less plastic is used, the ecosystem gains more. Products that are produced using extrusion molding are widely used worldwide. This method creates containers as well as jars, bottles and gas tanks. This would make something out of plastic more expensive and more accessible.

Advantages of Using EBM for Packaging

The best method for creating packaging is extrusion molding. It could produce a range of shaped and sized boxes. There are many shapes and sizes of jars and bottles. Moving is simple because of the boxes’ little weight. The box, despite its negligible weight , is sturdy. Its contents are protected inside. Enhancing a product’s blow-molded shape makes it more distinctive. This expedites the process and is less expensive.

Industries That Rely on Extrusion Molding

SBM and EBM blow molding are used in a wide range of industries. This facilitates their production procedure. The food company makes water, juice, and soda bottles. It is used in the production of vehicle components like fuel tanks. The cleaning industry uses it to produce soap and detergent bottles. In the medical sector, it is used to support claims made by doctors. Since extrusion molding offers robust, light, and safe items. These industries rely on it.

In the end,

EBM, is the last method used to make plastic products. The plastic will begin to soften more quickly if it is cooked. When it’s done, it’s rolled into a ” parison tube.” The tube inflates when air is forced into it. When placed within a mold, it adopts the form of the mold. It cools and becomes more complex. When it’s ready, the mold opens instantaneously. The item has been removed. We use EBM to make cases and glass. The process is short and easy to follow. Many of the things we use daily contain that chemical.