Introduction

Making hollow plastic goods through the industrial method known as blow molding is very common. It is a productive and economical way to make a variety of products, from toys and automobile parts to bottles and containers. We shall go into the specifics of blow molding in this essay, looking at its method, varieties, uses, benefits, and drawbacks.

What is Blow Molding?

In the manufacturing process known as blow molding, a heated plastic tube, or parison, is inflated inside a mold until it assumes the shape of the desired product. It is a flexible process that enables the fabrication of objects in a variety of shapes and sizes, making a wide range of applications possible.

The Process of Blow Molding

The blow molding process involves several key steps:

Extrusion: An extruder is used to melt the plastic material, which is often in the form of pellets or granules, and shape it into a continuous tube known as a parison.

Mold Clamping: The parison is sandwiched between two mold pieces before being clamped together.

Inflation: The parison expands as compressed air is fed into it, giving it the shape of the mold cavity.

Cooling and Solidification: Different techniques, such flowing water or air, are used to chill the freshly produced plastic object.

Mold Release: The finished item is ejected when the mold’s two parts are split.

Extrusion Blow Molding

The most popular type of blow molding is extrusion. The parison is extruded in this method vertically downward before being clamped in a mold. The finished item is removed from the mold after cooling and the mold is opened. Drums, containers, and bottles can be produced on a massive scale using extrusion blow molding.

Injection Blow Molding

The principles of injection molding and blow molding are combined in injection blow molding. A preform is created by injecting molten plastic into a mold cavity at the start of the procedure. The final product is formed by inflating and cooling the preform in a blow mold after it has been transferred there. Single-serve bottles and other small, intricate objects like medical equipment are frequently produced using injection blow molding.

Stretch Blow Molding

Several benefits of stretch blow molding include fine control over bottle dimensions, exceptional clarity and transparency, and high manufacturing efficiency. For the production of bottles for beverages, personal care items, and household chemicals, it is frequently used in the packaging sector.

Comparison of Blow Molding Types

Each style of blow molding has distinct qualities and benefits of its own. While injection blow molding is appropriate for small and complicated goods, extrusion blow molding is best for mass production of simple-shaped containers. On the other hand, stretch blow molding is ideal for creating bottles with exceptional clarity and dimensional accuracy.

Applications of Blow Molding

Blow molding finds extensive applications across various industries, including:

- Packaging: Bottles, containers, and jars for food, drink, cosmetics, and home goods are frequently made using the blow molding technique.

- Automotive: It is used to make parts for automobiles such reservoirs, ducting, and fuel tanks.

- Toys and Recreational Products: Toys, athletic goods, and other leisure goods are made using blow molding..

- Industrial and Agricultural Products: Toys, athletic equipment, and other recreational products are made using blow molding.

Advantages of Blow Molding

Blow molding offers several advantages that contribute to its widespread usage:

- Cost-Effective: Due to the process’ great efficiency, plastic products can be produced in large quantities at a lower cost than using conventional manufacturing techniques.

- Design Flexibility: To satisfy particular needs, blow molding permits the fabrication of intricate shapes and specialized designs.

- Lightweight and Durable: The end products are strong and impact-resistant while being lightweight, making them simple to handle, carry, and store.

- Material Variety: The selection of materials is flexible with blow molding because it works with a variety of thermoplastics.

Limitations of Blow Molding

While blow molding has numerous benefits, it also has some limitations:

- Design Constraints: Complex geometries or solid things are less suitable for the procedure, which is better suited for symmetrical and hollow structures.

- Wall Thickness Variation: It can be difficult to maintain uniform wall thickness throughout the molded product, which could result in differences in strength and structural integrity.

- Tooling Costs: Initiation costs for developing molds and tools can be substantial, especially for intricate designs or limited production runs.

Blow Molding vs. Injection Molding

Both the widely used plastic manufacturing techniques of blow molding and injection molding have unique applications. While injection molding is better suited for solid things, blow molding is typically utilized to create hollow ones. Every technique has advantages of its own, and the best one is chosen based on the particular needs of the product.

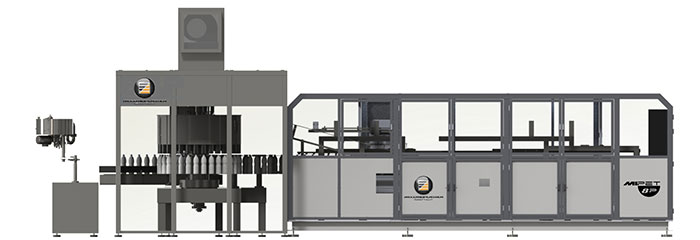

Blow Molding Machinery

Machines for blow molding are essential to the manufacturing process. They might be simple, single-station machines or big, fully automated systems that can produce a lot of stuff. Modern blow molding equipment uses cutting-edge technologies to increase productivity, efficiency, and accuracy.

Future Trends in Blow Molding

The field of blow molding continues to evolve, driven by technological advancements and market demands. Some emerging trends include:

- Sustainable Solutions: To reduce blow molding’s negative environmental effects, the industry is concentrating on producing eco-friendly materials and procedures.

- Advanced Automation: Systems for blow molding are being automated and robotically operated to increase productivity, shorten cycle times, and strengthen quality assurance.

Customization and Personalization: More customizable blow molding processes are being developed in response to consumers’ growing desire for bespoke goods.