Resin plastic injection molding is used to create substantial, lightweight plastic parts. Many industries use this method to produce high-quality products at a low cost. Businesses, from automotive to healthcare, rely on this technology to manufacture durable and precise parts. We’ll explore what Resin plastic injection moulding is, its benefits, and the industries that use it.

What is Resin Plastic Injection Molding?

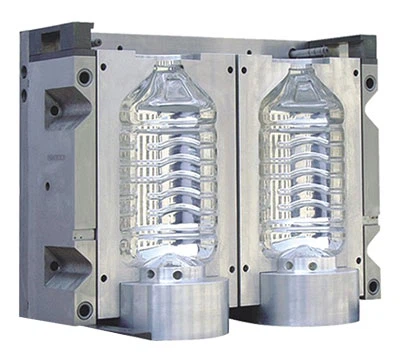

Resin plastic injection moulding is a manufacturing system that shapes plastic into stable gadgets. It works with the valuable resource of injecting melted plastic resin properly right into a mould below excessive pressure. Once the plastic cools, it hardens into the preferred form. This method allows manufacturers to create products in massive quantities with regular best. The technique is, in truth, eco-friendly, speedy, and cost-effective.

Benefits of Using Resin Plastic Injection Molding

The preferred production method is resin plastic injection molding due to its numerous benefits. First, it offers high levels of precision and consistency. Since moulds are designed with specific specs, each piece is identical, ensuring fantastic management.

Another benefit is fee performance. Once the mould is made, producing massive portions is reasonably priced. The device also reduces waste because unused plastic can be recycled and reused.

Durability is another key gain. Many resins are immune to impact, chemical compounds, and severe temperatures, making them ideal for demanding environments. Lastly, Resin Mold Manufacturing velocity is speedy. Once the mould is about, additives can be synthetic quickly, meeting excessive calls for correction.

What Industries Use Resin Plastic Injection Molding?

Many industries use custom Plastic Molding to supply critical components and products. Some of the primary sectors that benefit from this technology include:

Automotive Industry

BAutomobile manufacturers use resin injection moulding to make bumpers, dashboards, door panels, and other indoor components. This process involves many additives, sensors, and connectors underneath the hood.

Medical Industry

The scientific area upfield excellent plastic additives for devices. Industrial Plastic Manufacturing manufactures syringes, IV additives, surgical units, and synthetic joints. These injection molding materials must be sterile, long-lasting, and have resistant trances, making plastic an ideal choice.

Electronics Industry

Plastic is widely used in electronics, such as connector sternal additives. Resin injection moulding produces smartphone shells, distance-off controls, and computer components. The mantis method ensures precision and protects electronic additives from damage and environmental elements.

Consumer Goods Industry

Plastic injection molding is typically used for household products, kitchenware, and toys. This method effectively produces items such as bar containers, meal packaging, and plastic cutlery; its ability to create distinct designs and brilliant hues makes it a desired choice for client products.

Aerospace Industry

The aerospace industry uses plastic injection molding to manufacture lightweight, strong aircraft components. Plastic resins make interior panels, seat additives, and numerous structural additives. Buoyant plastics’ durability and warmth resistance help preserve protection and overall performance in aviation.

Construction Industry

Plastic injection moulding performs a massive role in producing substances and fasteners. These products want to resist harsh products that need stress, making long-lasting plastic resins.

Packaging Industry

Resin plastic injection moulding creates various packaging varieties, including bottles, caps, and packing containers. The food and beverage industry relies on this procedure to deliver secure, lightweight, clean packaging to move and store.

Some Resin Molds and Resin Molded Parts Available Online

Wide resin moulds and additives varieties may be determined online, catering to specific industries. Some famous classes consist of:

Automotive parts: These embody dashboards, trims, and shielding covers.

Medical additives include syringe elements, surgical equipment, and tablet boxes.

Electronic enclosures: Custom instances for gadgets, battery covers, and circuit board housings.

Household products: Kitchen boxes, water bottles, and ornamental items.

Industrial components: Gears, machine components, and safety devices.

Various websites and marketplaces provide custom resin moulds and moulded components. Businesses can choose from designs, materials, and colours to meet their precise wishes.

Resin Molded Products Supplier and manufacturer

Finding the proper dealer is crucial if you want the best resin-moulded products. One of the best producers in China is EX MOULD CO. This industry specialises in producing plastic components for numerous industries.

EX MOULD CO offers custom-designed moulding that permits companies to create specific, specialised parts. Their superior Plastic Injection Molding Process ensures accuracy, sturdiness, and cost-effective production. EX MOULD CO provides dependable answers tailored to your needs, whether you want medical additives, car elements, or digital casings.

They use terrific resin to ensure their High-Precision Molded Parts meet industry standards. With a robust reputation for excellence, EX MOULD CO is a trusted provider for businesses globally seeking the best resin-moulded products.

Key Takeaways

In many industries, thermoplastic Injection Molding is a vital production method. It provides a fee-effective way to supply long-lasting and precise plastic elements from motors to clinical devices, electronics to packaging. The technique’s benefits, which incorporate consistency, cost savings, and layout flexibility, make it vital.

Many resin moulds and moulded products will be available online, catering to numerous needs. If you are looking for a reliable supplier, EX MOULD CO in China is one of the quality options for brilliant resin moulded products. Their records guarantee top-quality production, making them a trusted partner for international companies.

With the development of plastic components, resin injection molding will play a key role in contemporary manufacturing. By choosing the proper provider, unmaterial materials agencies create exceptional products effectively and cheaply.