Plastic bottles are everywhere. They hold water, soda, shampoo, remedies, and more. But have you ever ever wondered how they may be made? The method behind their creation is known as plastic bottle molding. This process shapes plastic into bottles and is completed in remarkable industries. Injection Molding for Bottles is essential in modern lifestyles, from meal packaging to healthcare. We discuss what plastic bottle molding is, its types, and which industries rely upon it.

What is Plastic Bottle Molding?

Plastic bottle molding is a manufacturing device that shapes plastic into hole bottles. The method involves heating plastic till it turns smooth after molding it. Once cooled, the plastic hardens into the famous bottle shape. This plastic bottle manufacturing provides bottles for drinks, family products, and medicinal drugs. Plastic bottle molding allows mass manufacturing at a low fee. It moreover guarantees that bottles are lightweight, great, and reusable.

What Industries Use Plastic Bottle Molding?

Many industries depend on plastic bottle molding to create constant and available packaging. The beverage industry is considered one of the most essential clients of plastic bottles. Companies use them to package drinks such as water, juice, soda, and sports activities. PET Bottle Molding is best in this vicinity because they are lightweight, strong, and easy to recycle.

Moreover, the meal industry is based on plastic bottles. These bottles hold cooking oil, sauces, and condiments. They help keep food sparkling and protect it from contamination. They also help keep drug treatments regular from moisture and contamination. They are also shatter-proof, making them stronger than glass.

In non-public care and cosmetics, shampoo, lotion, hand sanitiser, and ordinary products are available in plastic bottles. These bottles are designed to be smooth and are proof of resistance to leaks. Many beauty agencies choose plastic packaging as it’s more assertive and decisive.

What Are the Types of Plastic Bottle Molding?

There are many styles of plastic bottle molding. Each kind has its advantages and is used for specific programs. The blow molding process is the most unusual to making plastic bottles. It entails blowing air properly into a heated plastic tube with a mold. The air expands the plastic, forming the shape of the bottle.

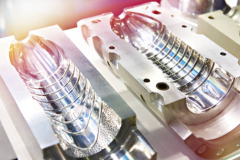

Injection molding consists of injecting melted plastic right into mold. The plastic is then cooled and solidified to form the bottle. This plastic Bottle Production is often used to create strong and unique bottle shapes, and it is very powerful for small plastic bins and caps.

Stretch blow molding combines injection and blows molding. First, the plastic is properly injection-molded into a small shape called a preform. Then, it is reheated and stretched to the interior of a blow mould to form a bottle. This method makes PET bottles, soda bottles, and water bottles.

Extrusion blow molding is a not unusual technique. It consists of compacting melted plastic through a tube, which is then inflated in a mildew to form the bottle. This device makes massive bottles for cleansing products and motor oil.

Why is PET Commonly Used for Plastic Bottles?

PET (Polyethylene Terephthalate) is one of the maximum not unusual plastics for bottle molding. It is appreciably used for packaging beverages, meals, and personal care merchandise. PET is usually used because it’s light-weight and best. It does not spoil without trouble, making it consistent for everyday use. It is likewise apparent, allowing customers to see the product indoors. PET bottles are recyclable and may become new clothing and products. PET is secure for food contact, making it a top choice for packaging drinks and great consumables.

Is Plastic Bottle Molding Environmentally Friendly?

Plastic bottle molding has every blessing and demanding situation regarding the environment. While plastic bottles are reachable and lightweight, they also contribute to pollution. However, efforts are being made to make plastic bottle manufacturing extra green. Recycling applications help lessen waste by reusing PET bottles. Many nations and agencies encourage recycling to limit plastic pollutants. Biodegradable plastics are superior to creating bottles that break down over time.

Reusable bottles are every other solution. Some producers now offer refillable plastic bottles to reduce single-use plastic waste. Manufacturers also use strength-green production techniques. They use much less energy and assets to supply plastic bottles, lowering their carbon footprint.

Custom Injection Molding Service Provider in China

If you are searching for satisfactory custom Bottle Molding services in China, EX MOULD Co is preferred. They focus on generating plastic bottle molds with precision and sturdiness. Their expertise in injection molding ensures clients receive quality, exceptional products at aggressive prices.

EX MOULD Co – The Industry-Leading Supplier of Custom Injection Molding from China!

EX MOULD has installed itself as a pacesetter in the plastic molding company. They provide custom injection molding offerings for a wide variety of industries, together with meal packaging, prescribed drugs, and personal care. Their advanced generation guarantees the best Molding Equipment for Plastic Bottles. They offer custom answers tailor-made to client desires. Competitive pricing makes them a preferred choice for international agencies. Fast shipping ensures short manufacturing and delivery, reducing wait instances for customers. Their strict best manipulation ensures durable and unique molds.

EX MOULD Co. is your go-to company in China if you want dependable and efficient plastic molding services.