Polyimide injection molding is essential for making strong and reliable additives for unique industries. We’ll explain the way it works, the industries that use it, its advantages, and the challenges it faces. You can even examine a leading employer, Plasticinjiectionmould, that gives high-performance plastics manufacturing.

What Is Polyimide Injection Molding and How Does It Work?

Thermoplastic injection molding is a methodology for making added substances using a stand-out plastic called polyimide. This material is strong, opposes warm temperatures, and doesn’t harm effectively, making it incredibly great for making components that need to oppose intense circumstances.

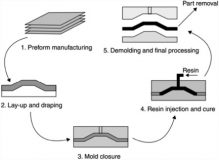

This is the secret: First, polyimide is warmed until it softens. Then, at that point, the softened polyimide is crashed into a mold.

The mold is fashioned just like the component you need to create. Once internal, the polyimide cools and hardens into the mold’s form. After cooling, people look at the part to ensure it’s ideal. This manner ensures that each piece is equal and works well.

What Industries Commonly Use Polyimide Injection Molding?

Polyimide injection molding is used in many industries because it makes strong and reliable elements.

Polyimide is used in the aerospace enterprise to make elements like airplane seals and insulators. These parts must withstand high heat and stress, and polyimide works well.

The automotive industry also uses polyimide. Polyimide-made car components like gaskets and sensors can last a long time, even in warm or greasy places.

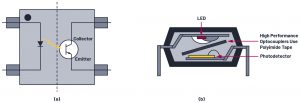

Polyimide is ideal for making circuit boards and wiring in electronics. It resists warmth and energy, keeping gadgets safe and running correctly.

Doctors and hospitals use polyimide in the medical enterprise for equipment like surgical contraptions and catheters. These gear must be strong and unique, and polyimide meets those wishes.

Polyimide components, such as gears and bearings, are also used in factories and machines. These elements experience a lot of motion and friction, but polyimide keeps them operating smoothly. In telecommunications, polyimide allows the manufacture of fiber optic components, which might be important for fast net connections.

Key Benefits of Using Polyimide in Injection Molding

Heat-resistant molded materials has many first-rate capabilities, making it a fantastic injection molding preference.

First, it can handle very excessive temperatures without melting or breaking. This makes it best for warm environments, like engines or electronics. Second, polyimide resists chemical substances like oils and acids. This means it doesn’t break without problems, even in harsh situations.

Another advantage is that polyimide could be very strong. It can bring heavy loads and live appropriately in the long term. This reduces the want for repairs or replacements. It also resists wear and tear, which helps parts last longer.

Custom polyimide components is also an excellent insulator. It prevents heat and energy from passing through, which is vital in electronics. Some forms of polyimide are self-lubricating, which means they lessen friction on their own. This is excellent for transferring elements like gears.

Challenges Are Associated With Polyimide Injection Molding

While polyimide is top-notch, its use in injection molding comes with challenges.

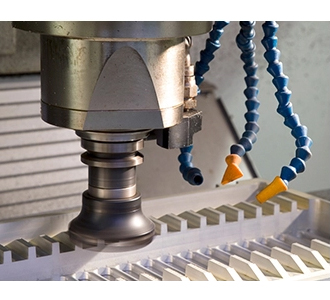

First, polyimide needs very excessive warmth to soften. This means special machines and educated workers are essential. These more needs can make the method more highly-priced.

Second, designing molds for polyimide components takes a lot of work. The molds must be concrete, especially for small or complicated components. This takes extra time and money.

Another mission is the cost of polyimide itself. It is more expensive than many other plastics. Because of this, a few groups would possibly hesitate to use it, although it’s the fine cloth for their needs. Finally, retaining excessive quality is a mission. Workers ought to carefully test every component to ensure it meets strict requirements.

How Does Polyimide Compare to Other Materials Used in Injection Molding?

Polyimide is a lot more grounded and more intensity-safe than most different plastics. For example, ABS plastic is more affordable, yet it might deal with something other than over-the-top temperatures or unforgiving synthetic mixtures at any point, as polyimide can.

Nylon is every other commonplace plastic. It is strong and resists heat. However, it still falls quickly in comparison to polyimide’s potential to handle excessive environments. Polypropylene is a famous, low-value plastic; however, it doesn’t remain as lengthy or sturdy under strain. While those materials are accurate for regular items, polyimide is the first-rate desire for components that must be painted in challenging conditions.

Consider When Choosing a Manufacturer for Polyimide Injection Molding

Choosing the proper business enterprise to make precision plastic molding services may be critical. First, look for a company with experience. Companies that have worked with polyimide before understand how to deal with its challenges.

Next, check if the corporation has the desirable best management. They need to check out each element carefully to ensure it works well. A top producer may even offer custom designs. This is vital because each industry has unique desires.

Finally, consider the price. Polyimide molding process can be expensive, so you need an agency that offers truthful charges without sacrificing quality. A proper producer balances price and quality.

Popular Manufacturer of Polyimide Injection Molding Services

One of the most businesses for Industrial polyimide applications is Plasticinjiectionmould. They have years of revel in and use advanced machines to create outstanding elements.

They offers many products, including custom mold layouts and mass manufacturing of polyimide elements. They additionally test each product carefully to ensure it meets high requirements.

This employer is known for supplying remarkable service at aggressive costs. They can assist you with small, precise, or big, sturdy components. Businesses from all over the world consider them for their polyimide injection molding needs.

FAQs

Why is polyimide so popular for injection molding?

Polyimide is robust, resists heat, and lasts long, making it best for demanding jobs.

Can polyimide be recycled?

Polyimide is only sometimes easily recycled. However, its lengthy lifespan reduces waste.

What industries use polyimide the most?

Industries like aerospace, automotive, electronics, and remedy use polyimide, which works well in intense conditions.

Polyimide injection molding is a clever way to make strong and reliable parts for many industries. From airplanes to scientific equipment, polyimide components are everywhere. With the proper producer, like Plasticinjiectionmould, you may create outstanding elements that meet all your desires.