When it comes to sourcing high-quality injection molding services, proximity matters. Whether you’re a product designer, engineer, or business owner, finding the right local partner can streamline communication, reduce lead times, and save on shipping costs. But how do you identify the best injection molding companies near you? Let’s explore key factors to consider and what makes a company stand out in this competitive industry.

1. What to Look for in an Injection Molding Company

1.1. Expertise and Experience

A company’s experience is a strong indicator of its capability. Look for firms that specialize in your industry or have a proven track record in producing similar products. Key areas to assess include:

- Material expertise: Can they work with the specific plastics you need (e.g., ABS, Polycarbonate, Nylon)?

- Part complexity: Have they handled intricate designs or tight tolerances before?

- Production volume: Can they handle both small batch and mass production?

1.2. Technology and Equipment

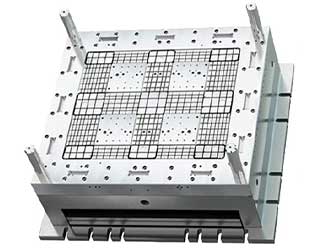

Top injection molding companies invest in advanced machinery and technology, including:

- Multi-cavity molds for high-volume production.

- Two-shot molding for multi-material parts.

- Robotics and automation to improve precision and efficiency.

Modern facilities often incorporate CAD/CAM software and real-time monitoring systems, ensuring consistent quality.

1.3. Customization and Value-Added Services

Beyond molding, many companies offer additional services such as:

- Product design assistance: Optimizing your design for manufacturability.

- Prototyping: Quick turnaround for design validation.

- Post-processing: Including assembly, painting, and packaging.

The best companies provide tailored solutions to meet your unique project requirements.

2. How to Evaluate Local Injection Molding Companies

2.1. Reviews and Testimonials

Start by checking online reviews or industry forums for feedback from other clients. Look for companies with consistent praise for:

- Product quality

- On-time delivery

- Customer service

2.2. Certifications and Compliance

Ensure the company meets industry standards. Look for certifications such as:

- ISO 9001: Quality management systems.

- ISO 13485: Medical device manufacturing.

- RoHS compliance: For environmentally safe products.

These certifications demonstrate a commitment to quality and regulatory compliance.

2.3. Visit Their Facility

If possible, schedule a visit. A tour of their facility provides insight into their capabilities, cleanliness, and workflow. You can also meet the team and discuss your project in person.

3. Benefits of Working with Local Injection Molding Companies

3.1. Faster Communication and Problem Resolution

Being in the same time zone or region enables quicker responses to queries and faster resolution of any production issues.

3.2. Reduced Shipping Costs and Lead Times

Local partners can significantly cut transportation costs and lead times, which is especially critical for tight production schedules.

3.3. Stronger Collaboration

Face-to-face meetings foster better collaboration, helping to refine designs and streamline the production process.

4. Top Industries That Rely on Injection Molding

Injection molding is widely used across industries, including:

- Automotive: For producing durable interior and exterior components.

- Consumer Electronics: Creating lightweight and precise housings.

- Medical Devices: Manufacturing sterile and biocompatible parts.

- Packaging: Custom containers and closures with high consistency.

Regardless of your industry, the right injection molding partner can elevate your product quality and ensure manufacturing success.

5. Conclusion

Finding the best injection molding companies near you doesn’t have to be a daunting task. By evaluating potential partners based on their expertise, technology, and customer feedback, you can identify a reliable company that meets your production needs. Remember, a strong local partner can help you optimize costs, improve quality, and bring your products to market faster.