An injection press or injection molding machine is the essential equipment for manufacturing plastic products using the plastic injection molding process. Here we’ll introduce the basic types of injection molding machines, which applying different mechanisms or principles.

Different Types of Injection Molding Machines

There are four basic types of injection molding machines, and many more types like rubber injection, metal injection, vertical injection, etc., these all come under the following categories.

1. Plunger Type Injection Molding Machine

The plunger injection molding machine uses the plunger to push the plastic in the barrel forward, make it pass through the diverter shuttle, and then inject it into the mold through the nozzle. The heat of plastic melting into a flow state is provided by electric heating outside the material Jane. Due to its simple structure, convenient operation, and low technical requirements, this plunger-type machine can meet the molding of general small parts or parts with fewer precision requirements. In the plunger machine, the diverter shuttle in the barrel needs to be studied and improved. It’s a simple method and used in small-scale industries for some small products, now it’s very rare.

2. Screw Plunger Type Injection Molding

In screw plunger type injection molding machine there are two chambers, one chamber is to plasticize the raw material and another chamber is used for injecting the material inside the mold, so upper section consists of plasticizing chamber in which the hopper is attached the material which is inside the hopper is transmitted in the plasticizing chamber and then the plasticized material will be transmitted to the injection plunger area (another chamber), then injection plunger will move forward and the material will be filled inside the cavities of the mold, the functioning of the screw is rotating and the material which is being plasticized has been accumulated in the injecting chamber, when you close the mold, the material is being charged from the hopper to the barrel, in the barrel section, there is a screw which is rotating and along with a screw, the barrel consists of some band heaters along with screw, they both helps in plasticizing the raw material, the melted raw material move toward another chamber which is called the injection chamber, in that injection chamber, there is a plunger which moves forward and the raw material which is in melted form is being injected inside the mold.

3. Plunger-Plunger Type Injection Molding

Plunger-plunger type injection molding machines and screw plunger type injection molding machines are quite common. The function for the plunger-plunger type injection molding machine is the same, instead of a screw which is in the plasticizing chamber. There is a plunger and heaters used for plasticizing, the functions of both the plunger type injection molding machine and a screw plunger type injection molding machine are quite similar, but the result and efficiency of a screw plunger type machine are more efficient than plunger type injection molding, in plunger-plunger type injection molding machine, the raw material is plasticized by heaters the band heaters which are being attached over the barrel and then the plunger moves that raw material into the injection plunger chamber and then what happened that injection plunger moves forward and the entire plasticized material is injected inside the mold.

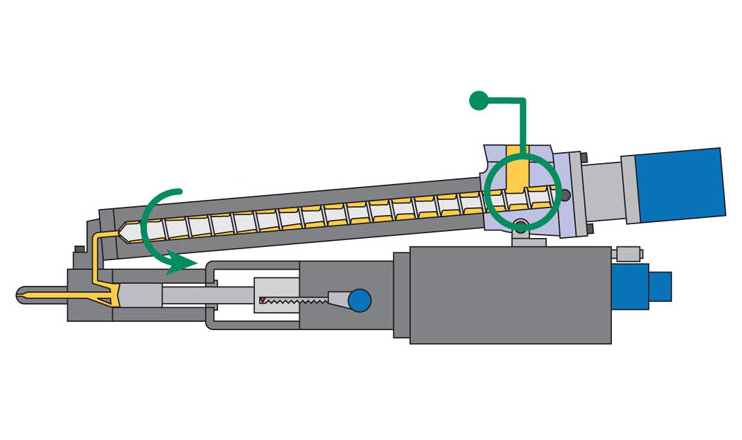

4. Reciprocating Screw Injection Molding

The heating elements are attached to the barrel, inside the barrel, there is a reciprocating screw, that’s why the name of the machine is called reciprocating screw type injection molding. The reciprocating screw is divided into three zones, which are feed zone, transition zone, and metering zone. In the feed zone, the material is transferred from the hopper to the barrel, transition zone also known as compression zone, the material is being compressed, the third is the metering zone in front of that screw there is an NRV which prevents backflow of material that it does not return back inside the barrel at the time of injection. When you charging the material from hopper to barrel but while rotating the screw backward, the material is being charged, now we have filled our barrel with the plasticized raw material, materials are basically in the granules, it’s time for injection. But before injection we have to close the mold using the clamping system either it is toggle ram or fully electric, when the mold is closed, the cooling pipes will cool down the mold with a temperature controller or water system. When you inject the plasticized raw material which has been accumulated inside the barrel, the reciprocating screw will move forward and the material is being accumulated over the tip of the screw material, material is being injected inside the mold, this process is done with high pressure, and this type is the most common and efficient injection molding machine in the plastic industries.