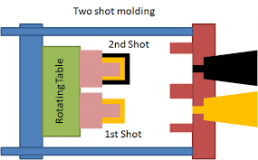

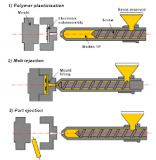

Custom plastic overmolding solutions is a game-changer in international production. It combines materials into a single product, giving it better electricity, features, and design. This approach can be the solution you desire to improve your manufacturing method. Let’s explore the top benefits of selecting injection over-molding offerings.

Top Benefits of Choosing Injection Overmolding Services for Your Manufacturing Needs

Enhanced Product Durability

Multi-material injection molding improves sturdiness by combining tough and tender materials. The base material provides energy, while the outer layer provides safety. For example, gear with rubberized grips is made using this process. These products are ultimately longer because they face up to put on and tear.

Improved Design Flexibility

This technique permits you to create precise designs. You can add a couple of layers of substances to make products that stand out. Overmolded product manufacturing helps producers meet customers’ needs, from colorful buttons to ergonomic handles. The flexibility also allows you to create complex shapes without extra steps.

Cost Efficiency

Precision molding services ultimately cuts expenses. It reduces the need for additional meetings by combining substances without delay, saving time and onerous work fees. Plus, fewer separate parts imply decreased risks of harm or loss.

Better Product Performance

By mixing substances, over-molding complements overall performance. For instance, merchandise can have improved grip, insulation, or waterproofing. These capabilities make items safer and easier to apply, which may be a massive advantage in industries like healthcare or electronics.

Eco-Friendly Production

Many over-molding offerings use recyclable materials, which reduce waste and help protect the environment. Additionally, fewer manufacturing steps mean less electricity consumption. If your enterprise prioritizes sustainability, over-molding is a clever choice.

Customizable to Your Needs

Thermoplastic overmolding process over-molding can cater to particular necessities. Whether you want softer edges or colorful hues, the procedure provides. Customization additionally helps you improve branding by including logos or textured surfaces.

Reduced Production Time

With over-molding, you combine steps into one procedure, accelerating manufacturing. Faster manufacturing methods and quicker transport for your clients give you an advantage over the competition.

Stronger Bonds Between Materials

Overmolding creates a secure bond between the bottom and top layers. This is higher than the usage of adhesives or screws, which may fail through the years. Strong bonds mean dependable, excellent products that clients can believe.

Common Uses of Injection Overmolding

Advanced injection molding techniques works appropriately for many merchandise, such as:

Medical Devices: Handles with smooth grips make equipment less complicated for doctors.

Consumer Goods: Toothbrushes, kitchen gear, and make-contact-with cases are often made in this manner.

Automotive Parts: This process benefits buttons, seals, and dashboard additives.

The versatility of over-molding makes it valuable throughout industries.

Why You Should Choose Expert Overmolding Services

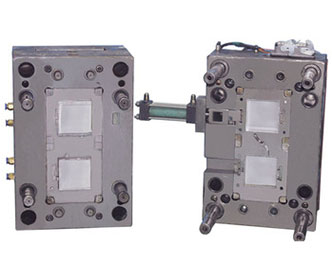

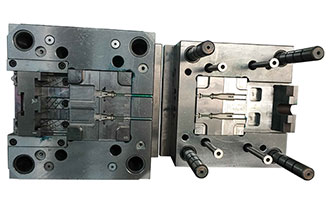

Skilled professionals make sure the system runs efficiently. They help with fabric choice, layout optimization, and production. Working with professionals reduces errors, which saves time and money. Plus, they provide consistent outcomes, and because of this, they are more delightful to purchasers.

Tips for Choosing the Right Overmolding Service

Check Their Experience: Look for an employer with confirmed know-how for your industry.

Ask About Materials: Ensure they can handle the precise materials you want.

Review Past Projects: Examples of their work can show their high quality.

Discuss Lead Times: Make sure they can meet your closing dates.

Who is the Best Injection Overmolding Services Provider in China?

EX MOULD Co. may be the pleasant issuer regarding plastic and rubber overmolding offerings in China. They have years of experience and supply pinnacle-exceptional results for custom merchandise. Their group uses advanced technology to ensure precision and sturdiness in every venture.

Whether you need prototypes or large-scale manufacturing, EX MOULD Co. It is a speedy and reliable provider. They combine substances to create strong, flexible, and specific merchandise. Their expertise spans industries like automobile, scientific, and customer items.

What makes EX MOULD Co. excellent is its commitment to consumer satisfaction. It works intently with clients to meet particular wishes, ensuring high-quality effects every time.

FAQs About Injection Overmolding

What materials may be utilized in injection overmolding?

Thermoplastics and elastomers are commonplace picks. Examples consist of nylon, polycarbonate, and silicone.

Is injection overmolding high-priced?

It might seem luxurious upfront, but it saves cash by decreasing assembly time and material waste.

How long does the over-molding procedure take?

The genuine time depends on the complexity of the product. However, it’s quicker than assembling components separately.

Final Thoughts

Injection over-molding offers many benefits, from improved sturdiness to price savings. It’s perfect for creating fantastic merchandise with unique designs and enhanced functions. Deciding on expert over-molding services could streamline your production technique and deliver advanced results to your customers.

Investing in injection over-molding is a smart move for any business looking to innovate, save money, and stay competitive. This method could fit your desires if you can take your merchandise to the next stage.