Have you ever wondered how plastic toys, phone cases, or car parts are made? Most of them come from a smart method called resin plastic injection molding. This method is fast, powerful, and used all around the world. It helps create strong, neat, and useful plastic items we use every day.

Learn what resin plastic injection molding is, what types of resins are used, why this method is popular, and what kinds of products it helps create.

What is Resin Plastic Injection Molding?

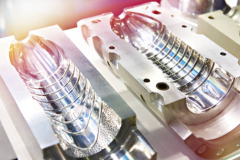

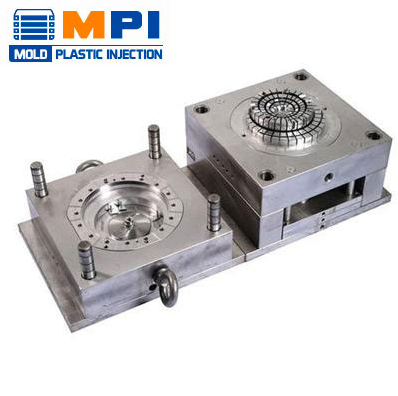

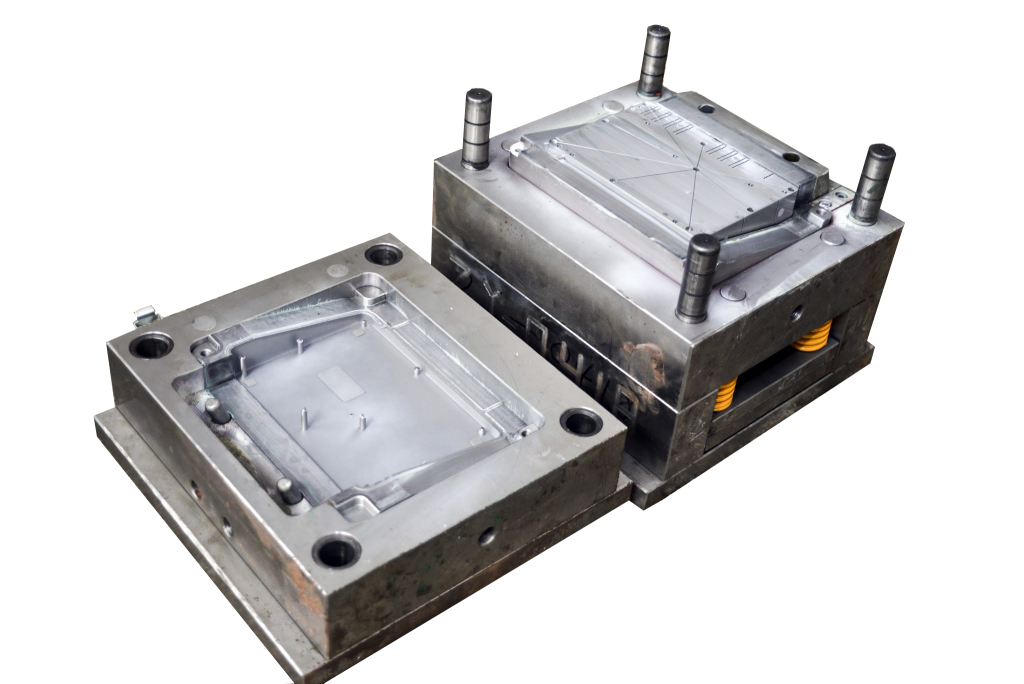

Resin plastic injection molding is a manner to make plastic shapes the usage of heat and pressure. First, small plastic pellets, called resin, are melted right into a warm liquid. Then, this melted plastic is driven right into a mold. A mould is type of a special pan or container fashioned like the final product. Once the plastic cools down and turns into a stable state, it pops out of the mould, and the product is prepared.

This method is top-quality for making a whole lot of the same issue. It’s quick and makes clean, strong items. That’s why many factories love the use of thermoplastic resin molding for all kinds of plastic items.

Common Types of Injection Molded Plastic Resins

There are many kinds of resins utilized in precision injection molding. Each kind has its special qualities. Some are hard and sturdy. Others are soft and flexible. Let’s have a look at a few famous ones.

- PEEK is a hard plastic. It can handle warmth and chemicals, which makes it best for machines and clinical tools.

- PLA is made from vegetation and is safe for the earth. It is frequently utilized in packaging and meal boxes.

- PVC is super for robust, weatherproof objects like pipes or outdoor products.

- Nylon is clean and slippery. It’s incredible for elements that move, like gears.

- Polycarbonate is clear and strong. It’s utilized in eyeglasses and home windows.

- Polyester is strong and holds its form properly.

- Polyethylene is bendy and often utilized in plastic bags and bottles.

- Carbon fiber resin is extremely strong and very light. It is utilized in planes, bikes, and vehicles.

- Polyimide resins can withstand very high temperatures and are regularly utilized in electronics.

Advantages of Resin Plastic Injection Molding

Resin plastic injection molding has many benefits. One of the largest is that it is able to make many parts very fast. This allows saving time and money. The method allows for making parts which are accurate. That way the final product appears neat and works simply right.

Another super component is that the waste may be very low. Any leftover plastic can frequently be used again. That makes it greater eco-friendly. Plastic mold manufacturing can also be used with many varieties of plastic, so it’s very bendy.

Also, the products made this manner are sturdy. Whether you need some thing tough, gentle, bendy, or warmth-evidence, this technique assist you to make it. That’s why it’s far used in many exclusive industries.

Applications of Resin Plastic Injection Molding

Resin plastic injection molding is used in many fields. It is found in houses, vehicles, hospitals, electronics, and even airplanes. In the auto industry, it enables the manufacture of components like bumpers, dashboards, and door handles. These want to be strong and capable of ultimate a long term.

In electronics, small components like phone instances, pc covers, and keyboard keys are made the use of this method. They want to be skinny, light, and robust. This method facilitates creating those elements fast.

In the scientific field, smooth and robust gears are desired. Resin molding allows the making of such things as syringe elements, plastic tubes, and medical packing containers. It’s extensively utilized in toys, packaging, sports systems, and even furnishings.

What Products Are Made Using Resin Plastic Injection Molding?

Almost each plastic item you notice around you may have been made the usage of this method. For example, plastic chairs, combs, kitchen gear, and water bottles. In toys, many action figures and building blocks are made with resin molds.

In packaging, plastic containers, caps, and trays are commonplace. Even toothbrush handles and cleaning soap instances are made the usage of this method. The reason is simple. It’s rapid, neat, and perfect for making large numbers of identical items.

Think approximately your smartphone. Its case, charger plug, and even the buttons may come from injection molding. The identical goes for automobiles, in which a few of the small and big components are plastic made with this method. It truly shapes the sector of plastic around us.

How Do I Pick the Proper Resin for Molding?

Choosing the proper resin is vital. You have to first reflect on what the final product will do. Will it be within the solar a lot? Will it need to bend or keep weight? Will it touch food, or need to be very smooth?

For gadgets that want to be strong and used in machines, PEEK is a clever choice. If the item should wreck down adequately in nature, PLA is quality. For water pipes or tough, outdoor products, PVC is robust and weatherproof. If the item will move or slide, like a tools, Nylon is clean and works well.

If the product need to be clean like glass however no longer spoil easily, Polycarbonate is ideal. And if you need some thing wonderful light however sturdy, carbon fiber resin works exceptional.

So, the job of the product facilitates you pick the right resin. It’s also an amazing concept to speak with professionals like engineers or resin mould makers.

Top Resin Molded Products Manufacturer in China

When it involves the Injection molded plastic parts in China, EX MOULD Co. is a name you can trust. EX MOULD is the best provider for Custom plastic molding services that specializes in designing and making precision plastic molds. They also handle the whole process of resin injection molding, from creating the mould to printing and spraying the finished product.

They work with many forms of resin materials. These include PEEK, PLA, PVC, Nylon, Polycarbonate, Polyester, Polyethylene, Carbon fiber, and Polyimide, amongst others. In that manner, they can deal with an extensive variety of Industrial plastic components, primarily based on what your assignment needs.

Whether you want parts which are robust, flexible, warmth-resistant, or long-lasting, EX MOULD has the proper tools and abilities. They are known for creating terrific and particular moldings that are constructed to remaining.

They also care about things like strength use, impact resistance, and ensuring every piece is identical. Their superior machines and professional workers help make the system clean and the effects outstanding.

If you’re searching for a trusted supplier of high-performance plastic resins, EX MOULD Co is the best choice in China. Their experience and care for quality make them a leader in the field.