Manufacturers have numerous molding techniques to pick from when making plastic components or merchandise, with every method imparting its very non-public advantages. Among those, plastic injection molding is the most well-known preference. But is it first-rate? Let’s dive into the Injection molding process and how it compares to big molding techniques and help you decide which approach is probably tremendous for your venture.

What Is Plastic Injection Molding?

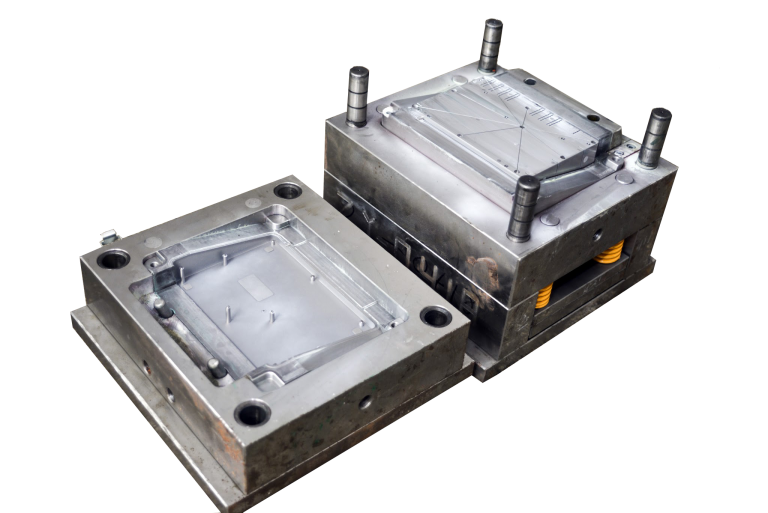

Plastic injection molding is a producing approach used to create factors by injecting melted plastic properly right into a mildew. The mold shapes the plastic into the preferred shape, which cools and hardens fast. Instead, This approach is green for making excessive volumes of identical elements, bottle caps, car factors, and hundreds of patron gadgets. Injection molding works well with several kinds of plastic, collectively with thermoplastics like polyethylene and polypropylene, making it very flexible.

Plastic Injection Mold vs. Other Molding: Which is Best?

Mold tooling for plastics is virtually one method among others. Let’s discover a few not-unusual options and notice how they look:

Blow Molding

Blow molding is frequently used to create holes in plastic products like bottles or packing containers. In blow molding, the air is blown into heated plastic to shape it properly into a mold. This method is first-rate for lightweight gadgets with a hole shape; however, it’s not super helpful in making complicated or robust gadgets. Unlike injection molding, blow molding has limited layout flexibility and isn’t as green for developing positive, immoderate-precision elements.

Which is better? Blow molding might be excellent if you’re making hollow, lightweight containers. However, injection molding commonly provides more precision and versatility for robust or unique gadgets.

Rotational Molding

Rotational molding, referred to as “roto-molding,” includes heating plastic in a mold that rotates slowly on one-of-a-kind axes. This method is excellent for growing large, hollow merchandise, like garage tanks, kayaks, and playground devices. While it’s beneficial for large devices, rotational molding takes longer to deliver every factor, making it flawed for excessive-pace manufacturing.

Which is better? Rotational molding is suitable for large, hollow products that need electricity. But if you need small, positive devices fast, injection molding is more efficient and specific.

Compression Molding

Compression molding is a method in which a plastic cloth is positioned in a heated mold and then compressed to shape it. This technique is typically used for thermoset plastics, such as those found in electric devices and kitchenware. Compression molding is relatively less expensive and creates durable gadgets. However, more detail, precision, and speed are needed for injection molding.

Which is better? Compression molding works nicely for durable gadgets, mainly with thermoset plastics. However, plastic injection molding is typically faster and more flexible for excessive production of particular factors.

Extrusion Molding

Extrusion molding makes lengthy, non-forestall shapes, like pipes, sheets, or straws. The system pushes heated plastic through a die to create a uniform shape. While it’s a brief and coffee-rate technique for non-save products, extrusion molding isn’t perfect for growing character additives with complicated plastic mold designs.

Which is higher? For non-prevent shapes like tubing or sheets, extrusion molding is exquisite. But in case you’re generating separate, remarkable additives, injection molding offers higher precision and versatility.

Advantages of Plastic Injection Molding

Thermoplastic injection molding stands out in plenty of strategies:

- High Precision: It’s regarded for its capability to create particular, rigid designs that can be precisely alike.

- Efficiency in Large Batches: Once the mold is ready, injection molding can quickly produce hundreds of equal elements.

- Wide Range of Materials: Injection molding works with many plastics to adapt to the dreams of particular commercial company agencies.

- Cost-Effective in Bulk: Although the preliminary mildew setup is expensive, producing massive batches reduces the charge in step with the thing.

Disadvantages of Plastic Injection Molding

Despite its benefits, plastic injection molding does have some obstacles:

- High Initial Cost: Creating custom mildew may be costly, making this technique much less effective for small manufacturing runs.

- Material Wastage: The technique can occasionally produce material waste, even though recycling is feasible only occasionally.

- Not Ideal for Hollow Products: Injection molding works first-class for sturdy components and might need to be greener for hollow shapes to evaluate blow or rotational molding.

So, Which Molding Technique Is Best?

Choosing the notable molding approach is based totally upon your venture dreams:

- Plastic injection molding is usually a terrific preference if you make immoderate volumes of solid and nice elements.

- If you want the hole, slight-weight products (like bottles) and blow molding may be the stronger desire.

- Rotational molding is outstanding and wholesome for large, hollow gadgets (like tanks or playground devices).

- Extrusion molding can be satisfactory when developing non-prevent shapes like pipes or sheets.

Who is the top Plastic Injection Mold manufacturer in China?

EX MOULD Co., primarily based in 2006, is China’s top Plastic mold manufacturer. Known for terrific custom injection molding, EX MOULD Co. serves clients globally with precision and reliability. They focus on developing molds for diverse industries, including automotive, electronics, and purchaser goods.

With years of experience, EX MOULD Co. has built a reputation for sturdiness, accuracy, and fast shipping. Their advanced generation and strict super tests ensure that every mold meets actual requirements. They additionally focus on client pride, supplying customized services to fulfill particular task needs.

FAQs

What is the principal benefit of plastic injection molding?

The predominant gain of custom plastic molding is its general performance in producing excessive volumes of precise, identical additives. It’s best for growing precise, robust additives at a low charge in step with the object as soon as the mildew is prepared.

Is injection molding more expensive than excellent techniques?

Yes, the preliminary setup price of plastic injection molding is higher because of the introduction of mold. However, it will become fee-effective for huge batches, decreasing the fee while keeping with details.

Which molding approach is brilliant for hollow merchandise?

Blow molding and rotational molding are higher for hollow products. Injection molding works top-notch for sturdy, particular additives.

In Wrap Up the Plastic Injection Mold vs. Other Molding

Plastic injection molding is one of the greenest and most versatile molding techniques available today. While it has a higher startup price, it gives precise, steady results for large quantities. For excessive-quantity tasks that require pleasant detail, injection molding is often the top choice. However, you can pick the quality one based on your unique needs by understanding the strengths of each molding method.