22

2023.6

Plastic Moulding Process: A Comprehensive Guide

The process of molding plastic materials into different shapes is known as plastic molding and is a common manufacturing technique. It is a flexible and economical technique that has transformed the manufacturing of plastic goods in a variety of sectors. We shall go into great length about the plastic molding process in this post, including its different methods, benefits, uses, and other topics. Introduction to Plastic Moulding Plastic materials are shaped usi......

22

2023.6

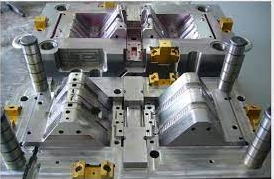

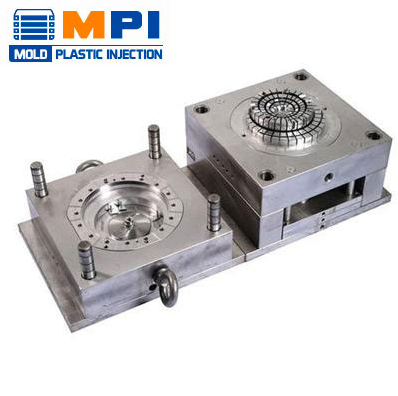

Making mold tools is a critical step in the manufacturing process. It entails making precise tools that are used in a variety of industries, including the automotive, aerospace, and consumer products industries. We will go into great detail about mould tool manufacture in this blog post, including its definition, method, benefits, and uses. What is Mould Tool Making? Making mold tools is the process of creating tools with exact shapes and dimensions tha......

22

2023.6

Plastic Moulding: Shaping the Future

The way we manufacture plastic goods has been transformed by plastic molding, a flexible manufacturing method. Plastic molding has developed into a vital technique for making everything from everyday products to complex parts for numerous industries. This article will examine what plastic molding is, its numerous forms, its benefits, and its effects on various industries. Therefore, let us explore the world of plastic molding and learn how it affects our future. ......

22

2023.6

Custom Plastic Mold Injection Molds: Revolutionizing Manufacturing Processes

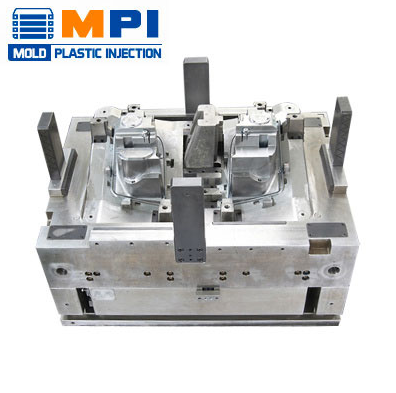

Introduction Custom plastic mold injection molds have become a crucial tool for manufacturers in a variety of industries in today’s quickly changing industrial landscape. The manner that items are created, prototyped, and mass-produced has been changed by this cutting-edge technology. Custom plastic mold injection molds have many advantages that improve productivity, quality, and cost-effectiveness by facilitating accurate and effective manufacturing proce......

20

2023.6

What Is Blow Molding: A Comprehensive Guide

Introduction Making hollow plastic goods through the industrial method known as blow molding is very common. It is a productive and economical way to make a variety of products, from toys and automobile parts to bottles and containers. We shall go into the specifics of blow molding in this essay, looking at its method, varieties, uses, benefits, and drawbacks. What is Blow Molding? In the manufacturing process known as blow molding, a heated plastic tube, o......