14

2025.3

7 Major Advantages of Soft Plastic Injection Molding

Soft plastic injection molding is a popular manufacturing process for creating flexible, durable, lightweight plastic parts. It is significantly applied in many industries due to its everyday primary performance and price effectiveness. This strategy allows manufacturers to offer exceptional plastic products with unique shapes and soft finishes. We will learn about soft plastic injection molding, the various soft plastics used, the advantages of each, and the indu......

14

2025.3

Injection Overmolding: Benefits, Technologies, and Industries

Injection overmolding is a substantially used manufacturing process that enhances a product’s energy, durability, and look. It molds one fabric over another to create a seamless element. This process improves the product’s conventional performance and reduces manufacturing time. Many industries depend on overmolding for better-quality devices, clinical gadgets, electronics, and car components. This text teaches us about the advantages, technology, and ......

5

2025.3

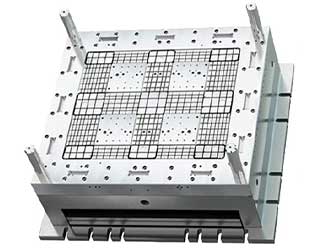

What to Know About Insert Molding: Process and Design

Insert molding is an advanced plastic injection molding technique used in many industries. It helps create strong, durable, and lightweight elements. This method improves product popularity, average overall performance, and price reductions. Manufacturers choose Plastic injection molding for its performance, precision, and ability to integrate several components into one strong piece. We’ll discuss the insert molding gadget, materials, benefits, programs, an......

5

2025.3

Injection Blow Molding – Materials, Types, and Applications

Injection blow molding is famous for producing plastic bottles and hollow components. It is extensively completed in the pharmaceutical, cosmetics, and meal packaging industries. This machine guarantees precision, consistency, and overall performance in manufacturing. Businesses rely on hollow plastic product manufacturing as it produces exceptional products with minimum waste. This text will teach about injection blow molding, the materials used, and the differen......

2

2025.3

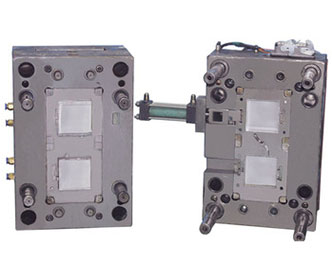

Why Choose Custom Injection Molding for Precision Parts

In today’s competitive manufacturing landscape, precision and customization are critical factors for businesses seeking high-quality components. Whether you are in the automotive, medical, electronics, or consumer goods industry, custom injection molding provides unparalleled advantages. But why should you choose custom injection molding for precision parts? Let’s explore the benefits, processes, and key considerations in making the right choice for your productio......