The automotive industry constantly seeks better ways to manufacture car parts while reducing environmental impact. One of the most widely used techniques is plastic injection molding. This process produces terrific plastic components for motors, but many wonder if it is environmentally friendly. This article will discuss the advantages and challenges of automobile plastic injection molding regarding sustainability.

What is Automotive Plastic Injection Molding?

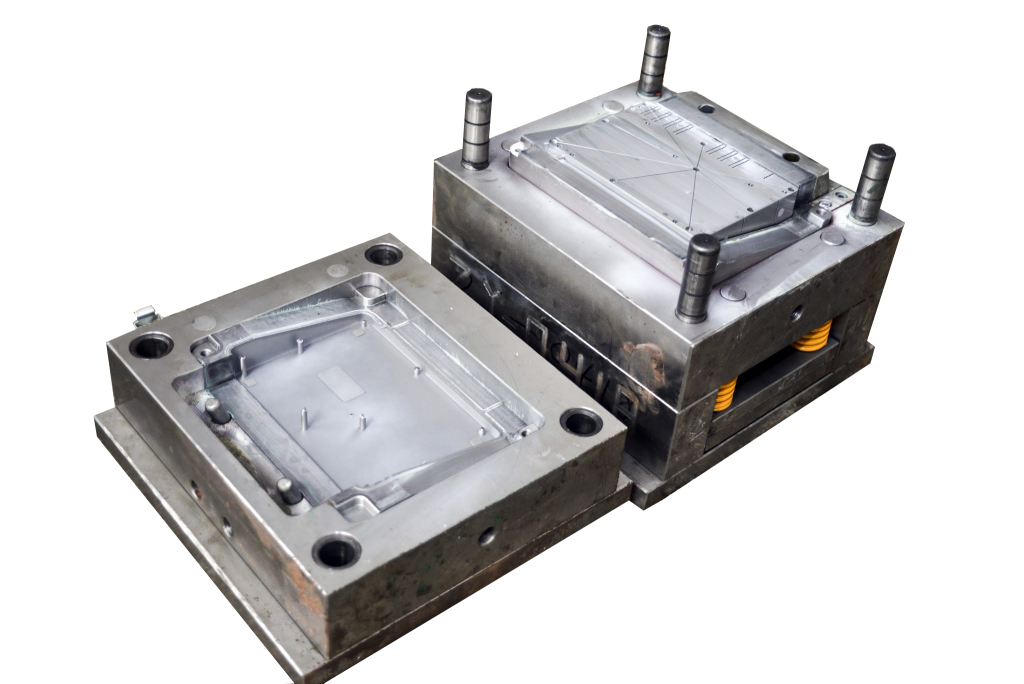

Automotive plastic injection molding is a gathering cycle that makes precise plastic parts by injecting fluid plastic appropriately and solidly into a mold. Once cooled, the plastic forms a mold, forming durable Injection molding applications. This process is significantly used in automobile organizations because of its performance, accuracy, and ability to offer complex factors in significant volumes.

This technique is used on many car elements, including bumpers, dashboards, and door panels. It guarantees serious strength for lightweight, practical parts, making it a famous decision for automakers worldwide.

Is Automotive Plastic Injection Molding Environment Friendly?

Plastic molding machines are both excellent and environmentally friendly. On the one hand, it produces lightweight car additives, enhancing gas performance and decreasing carbon emissions. Lighter cars consume a whole lot, plenty much less gasoline, principal to lower pollution tiers. Additionally, recycled plastics are significantly used in this manner, assisting in lessening waste and reliance on uncooked substances.

However , thermoplastic materials do have environmental drawbacks. The method calls for electricity to warm plastic and characteristic machines that could produce carbon emissions if powered through non-renewable strength property. Additionally, plastic waste from rejected components and fabric can contribute to pollutants if not properly recycled.

Types of Plastic Used in Automotive Injection Molding

Different plastics are utilized in automobile injection molding, counting on the software. Some of the most not unusual embody:

- Polypropylene (PP)- Lightweight, powerful, and evidence nearer to synthetic mixtures, making it quality for inside and outside vehicle parts.

- Acrylonitrile Butadiene Styrene (ABS) – Strong and influence-safe for dashboards and trims.

- Polycarbonate (PC) – Transparent and shatter-resistant, typically in mild covers and windshields.

- Nylon (PA) – Strong, heat-resistant, appropriate for engine additives and under-the-hood factors.

- Polyvinyl Chloride (PVC) – Adaptability and climate safety are achieved in seals, gaskets, and interior panels.

Benefits of Plastic Injection Molding within the Automotive Industry

Plastic injection molding offers different benefits to every producer and client. One of the most essential benefits is price effectiveness. The technique allows mass manufacturing at a lower fee, making plastic factors extra a lot, a good deal, and much less pricey than metallic options.

Another key advantage is weight reduction. Plastic components are notably lighter than metal, helping automobiles consume less fuel and lower carbon emissions. Additionally, mold design and production ensure excessive precision and consistency, allowing car producers to provide the same components with minimum defects.

Durability is one of the most unique and vital gains. Various vehicle plastics are designed to withstand extreme temperatures, UV exposure, and mechanical pressure, making them ideal for delayed-enduring car components.

What Automotive Parts Are Made Using Injection Molding?

An impressive style of car parts is synthetic, which utilizes custom molded plastic parts . Some of the most not unusual elements encompass:

- Exterior components incorporate bumpers, grilles, and aspect panels.

- Interior elements like dashboards, door panels, and cup holders.

- Under-the-hood additives include air consumption manifolds, engine covers, and battery casings.

- Lighting factors like headlamp lenses and taillight covers.

- Small practical additives at the facet of fasteners, clips, and gaskets.

Because of its flexibility and precision, injection molding is one of the car region’s most significantly used manufacturing strategies.

How Can the Injection Molding Production Process Be Made Greener?

The car company is taking steps to make plastic manufacturing techniques more environmentally friendly. One critical technique is using recycled substances. Many manufacturers within the endorsed time are incorporating post-client and located up-commercial recycled plastics into their production, decreasing the want for current raw materials.

Another key improvement is an electricity-inexperienced device. Advanced injection molding machines use much less electricity and perform with minimal waste, decreasing traditional emissions. Some factories are even switching to renewable electricity assets to lessen their carbon footprint further.

The development of biodegradable and bio-primarily based plastics is likewise making a difference. These materials have broken down clearly over the years, lowering plastic pollution. Additionally, companies are adopting closed-loop recycling structures, where extra plastic from the manufacturing process is accumulated, reprocessed, and reused.

By enforcing those greener practices, automobile plastic injection molding can grow into a more sustainable production method with minimal environmental effects.

How Do You Identify a Sustainable Plastic Injection Molding Partner?

Considering that you’re looking for an unpracticed injection molding acomplice, consider different factors. First, check whether the employer uses recycled or biodegradable plastics in its manufacturing. This shows a dedication to sustainability.

Next, examine the producer’s average power performance. Companies that use power-inexperienced systems and renewable energy assets have a decreased environmental impact. Additionally, inquire about their waste control practices. A responsible organization should have a device for recycling plastic waste and lowering emissions.

Certifications are also essential. Look for producers with ISO 14001 (Environmental Management) certification, which ensures they agree to sustainable practices. Finally, the industry employer’s transparency should be considered. A reliable accomplice will openly disclose its sustainability efforts and responsibilities, demonstrating an actual determination to be environmentally responsible.

Top Automotive Plastic Injection Molding Manufacturer in China

One of China’s top vehicle plastic injection molding producers is EX MOULD Co. This commercial agency has over 10 years of experience in excellent custom plastic molded products. It offers various services, from consulting and format to prototyping and production.

EX MOULD focuses on commercial company-grade plastic factors, speedy injection molding, and coffee-to-mass-amount manufacturing. Their price-green and time-effective solutions motivate them to be dependent on issuers for automobile producers worldwide.

The industry is dedicated to excellent requirements and client satisfaction, ensuring every injection mold meets industry necessities. Whether you want custom prototypes or large-scale production, EX MOULD Co. offers 100% quality injection molds.