Injection overmolding is a substantially used manufacturing process that enhances a product’s energy, durability, and look. It molds one fabric over another to create a seamless element. This process improves the product’s conventional performance and reduces manufacturing time. Many industries depend on overmolding for better-quality devices, clinical gadgets, electronics, and car components. This text teaches us about the advantages, technology, and industries that use Plastic injection molding.

What is Injection Overmolding?

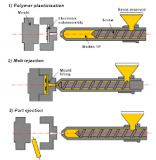

The overmolding process is a specific molding technique in which a clean or bendy material is injected over a rigid base cloth. This creates a best bond with maximum materials, enhancing comfort, grip, and sturdiness. The base material, called the substrate, can be metal or plastic. The second or oversold layer is the essential easy plastic or rubber. This process eliminates the need for adhesives or mechanical fasteners.

What are the Benefits of Injection Overmolding?

Injection overmolding benefits manufacturers and customers. One crucial gain is advanced product durability. The overmoulded layer provides more electricity, making the product extra resistant to wear and tear. This is particularly beneficial for machines, scientific devices, and electronics that must last a long time.

Another gain is better grip and comfort. Handheld gadgets like razors and electric devices use overmoulding to provide a non-slip floor. This makes them less challenging to maintain and more steady to apply. Overmoulding reduces production fees by combining multiple factors into a single piece. Since no more excellent assembly is needed, manufacturers save time and money.

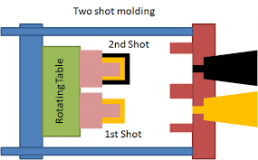

Overmolding improves the advent of products. The seamless layout gives an expert and fantastic appearance. It additionally allows for personalisation with unique colors, textures, and symbols. Finally, Two-shot molding provides insulation and protection. It helps defend electronics from moisture and surprise, ensuring they perform well under challenging conditions.

Key Technologies and Features of Overmolding

Insert molding technology involves advanced molding techniques to ensure a strong bond among substances. One key generation is the usage of Thermoplastic elastomers (TPE). These are bendy substances that bond well with inflexible plastics. TPE is extensively used for grips, seals, and protective layers.

Another advantage is enhanced grip and comfort. The mould wants to be cautiously designed to fit each bottom fabric and the overmold. This ensures the materials bond effectively without gaps or prone spots. Proper mildew design moreover prevents defects like air bubbles or terrible adhesion.

Temperature and strain manipulation play a massive role in successful overmolding. The temperature should be extreme enough to melt the overmold cloth but not too extreme to harm the base. Pressure should be managed to ensure an even distribution without deforming the substrate.

Some over-molding techniques use chemical remedies to beautify adhesion. Surface remedies help the 2 substances stick together better, stopping peeling or separation. Laser texturing and plasma treatments are common strategies to beautify bonding.

What Industries Use Injection Overmolding?

Many industries use injection overmolding to create fantastic, long-lasting products. One of the most critical employers is clinical devices. Overmolding helps produce snug and sterile devices, including surgical devices, syringes, and catheter handles. The mild overmolded layer gives a better grip and reduces patient pain.

The automotive industry is additionally based on overmolding. Many car factors, together with guidance wheels, dashboard panels, and tool knobs, use this method. Overmolding lets in reduces vibrations, enhances aesthetics, and grows sturdiness. It also allows the creation of waterproof and heat-resistant additives for higher typical overall performance.

Overmolding protects sensitive components from water, dust, and other environmental factors in the electronics industry. It is used in cables, chargers, and battery covers. This process provides a further layer of insulation, ensuring the comfortable operation of virtual gadgets.

Lastly, the economic vicinity uses overmolding for equipment components, protective cases, and hand gear. These products require the best designs, which overmolding offers.

What Factors Affect the Quality of Injection Overmolding?

Several factors decide the success of a Multi-material molding device. One essential detail is cloth compatibility. The base cloth and the overmold ought to bond well collectively. If they are not like-minded, the layers can also peel or separate over time. Manufacturers carefully choose materials that adhere well without using extra adhesives.

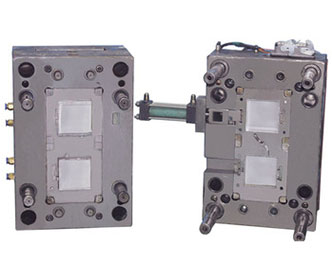

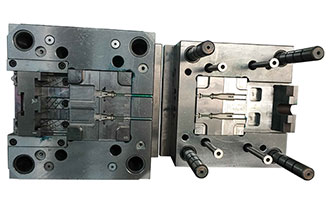

Mold format is every other critical element. The mold must be designed with precision to ensure the best shape is created. If the mould is not nicely made, the final product may have defects like choppy surfaces, gaps, or air pockets. Proper venting and gating techniques are critical to avoid those problems.

Temperature and pressure settings also play a significant role in excellent overmolded components. If the temperature is too low, the overmold might not bond well. If it’s far too high, it can damage the base cloth. Pressure must be adjusted successfully to ensure even distribution without deforming the product.

Surface training affects the final bond electricity. Some materials, collectively with plasma or chemical remedies, require pre-remedy to enhance adhesion. Proper floor cleaning eliminates dirt, oils, and contaminants that might weaken the bond.

Lastly, manufacturing speed and cooling time impact overall quality. Cooling too fast can cause warping while cooling too slow might also cause defects. Manufacturers cautiously manipulate those factors to deliver exceptional over-molded components.

Excellent agency for Injection Overmolding Services in China

EX MOULD Co. can be an excellent agency for China’s plastic and rubber overmolding services. They have years of experience and deliver outstanding results for custom products. Their employer uses advanced generation to ensure precision and sturdiness in each undertaking.

Whether you want prototypes or large-scale production, EX MOULD Co. It is a speedy and dependable company. They integrate substances to create sturdy, flexible, and unique products. Their information spans industries like vehicle, scientific, and purchaser gadgets.

What makes EX MOULD Co. excellent is its willpower and customer pride. It works carefully with customers to meet unique needs and ensure high-quality results on every occasion.