The audience for this guide would be design engineers and manufacturing engineers who are developing or manufacturing plastic injection molded parts. this guide intends to be more of a holistic overview of the molding process, it’s not an exhaustive analysis into injection molding, but it will give you some insight into the top issues that we as contract manufacturers contend with when we’re working with your plastic design parts and the intent is to allow you to design parts that are better and at the same time cheaper.

1.The first guideline for injection molding is to utilize constant wall thickness.

Injection molded parts will shrink according to how thick the part is in a certain area. a part that’s been designed with a consistent wall will shrink in a consistent and very predictable manner, whereas a part that has different thicknesses will shrink in different amounts in those directions and will cause unsightly sync and cosmetic error. it’s important to make sure that the material thickness is constant throughout the part. this also eliminates some flow anomalies, like getting currents which are going to create other cosmetic defects in the part. another benefit of having a constant wall is that it will cool in the least amount of time possible. the majority of the cycle time or the time it takes for the part to eject from the mold is wrapped up in cooling. the less wall thickness you have and the more consistent your wall thickness is the less cooling time and the less money you’ll have to spend on that part.

2. The second guideline for injection molding is to utilize ribs and bosses for structures.

Ribs and bosses are surfaces that extend off of the nominal wall some amount to reinforce structurally the part in that area. you want your wall thickness to be roughly 50 to 60 percent of your nominal wall. however, the thick your wall is can change will dictate how wide the rib is. ribs can give you strength in a third order, the taller the rib is will give a lot of strength relative to its height. it’s a great way to add strength and structural rigidity to apart without thickening the nominal wall. even on the wall is going to cause a lot of additional cooling time and additional cost. use local reinforcement with ribs to create structural rigidity.

3.The third guideline for injection molding is to avoid sharp corners and transitions.

This is for several reasons, but the material is going to flow around these corners when it fills the mold. don’t let it transitioning from thick to thin, then too thick sections again. you don’t want to transition certainly from thin to fat sections, which causes a lot of material flow issues. we want a nice constant wall through the parts that it’ll flow around these corners very easily. also, from a stress standpoint, there’s a very strong correlation between sharp corners and mechanical failures and products. make sure that we keep all our corners nice and round, we’re going to have failures when they’re put under stress.

4.The fourth command of injection molding is to avoid thin sections and thin steel.

There’s a lot of force involved in injection molding up to 18,000 PSI. with that kind of force if you have thin steel conditions or thin sections in the mold when that has a force is imparted on, it can create break the mold or sections. make sure that you don’t have thin narrow sections in the mold, which could break. talk to your custom molder on what geometry changes need to be made so that you don’t have these conditions. in addition to that, it may also make it harder to machine. when you have thin sections in a mold, it’s hard for a work center or an NC to get their cutter down in those thin sections. it’s a lot easier if we use nice big fat sections on parts to do that.

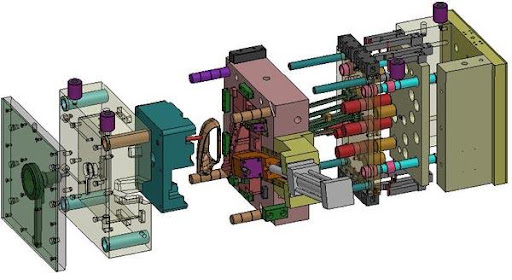

5.The fifth guideline of injection molding is to avoid undercuts or side action.

Undercuts our areas in the mold, where the steel cannot pull or open without interfering with the parts. when designing the molds, eliminate these types of side actions. if you do have side action, these may have to have hydraulic cylinders to move steel in out, or sliders/lifters which do the same thing, they move the steel. this complicates the molds, increases the mold cost and cycle time. it also decreases the life in mold. there’s a lot of reasons why you want to be careful to avoid side action in your injection molding parts, a lot of times it can’t be avoided, it’s not something that is that we can’t work around or the injection motors or customer orders are not used to working with, but there is a cost to it. a good DFMA is designed for manufacturing assembly exercise would rule this out, you might be able to take this part, break it up into two separate parts that are bonded together, or eliminate the side action in some other way, but it’s something that we need to be cognizant of when we’re designing injection molded parts is to minimize or mitigate the amount of side action we have.