If you take a close look at the products around you, you’ll notice that many are made of parts that have been assembled together. One way factories make product parts is by melting materials such as metal rubber or plastic, then pouring or injecting them into molds to make a plastic part for a product. The manufacturer has to first commissioned a mold making company to design and produce a plastic injection mold. And EX MOULD can be a great choice which is committed to providing high-class custom injection molding services. Now read on this article to get to know the plastic injection mold making process.

Injection Molding Making & Manufacturing – How To Make Plastic Injection Molds?

Follow theses tips on how to make molds for injection molding:

Bars of chromium steel

The mold begins as bars of chromium steel, a high durability metal that can withstand repeated high pressure. Injection of plastic workers assemble several bars into a block called a mold base, they mount the base on a milling machine which shaves the bars to the right dimension, this step is critical enabling them to later machine the base into a mold, that’s faithful to the technical design right down to the hundredth of a millimeter.

Drill holes

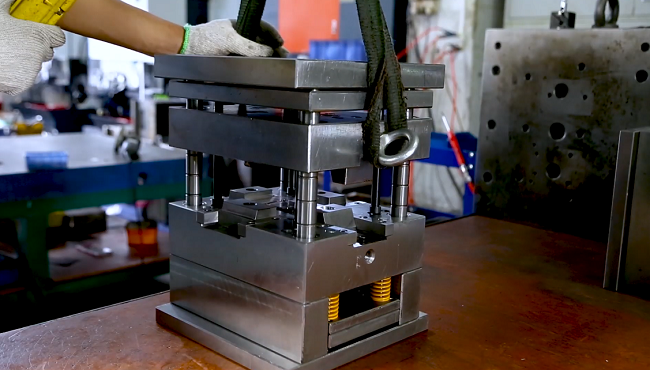

A mold usually consists of two halves, each of which is comprised of several components, the factory drills strategically positioned holes in the bases for the guide pins and bushings that hold the components together. When the plastics injected a grinder, go to work smoothing and leveling all surfaces, this prepares the base for the high precision machining operations that will transform it into a mold component.

Create the mold components shape with CNC slowly machines

A computer-guided tooling machine called the CNC slowly machines, the base wearing away the steel particle by particle to create the mold components shape, this one part of a mold for the plastic rim around a snowmobiles front headlight takes 20 hours to complete. Most mold components go on to a second tooling machine especially if they have some fine detailing that this CNC machine is incapable of carving.

Verify the dimensions

The second machine is outfitted with a copper electrode in the shape of the plastic part. In this case, a snowmobile oil gauge after polishing the electrode to ensure flawless casting, they use a sophisticated measuring device to verify the dimensions, the electrode goes facedown.

On the second tooling machine called the EDM, directly underneath is the mold half that’s already been partially formed on the first machine, a strong electric current runs through the electrode and penetrates the mold forming a cavity in the shape of the electrode. After tooling, they drill coolant lines, this is for the cooling fluid, they’ll use to accelerate the hardening of the molten plastic.

Extract the molded plastic part

The surface of the mold cavity is pretty rough from all that tooling, so they polish it smooth to ensure a proper casting. The mold look like the pins and bushings fit together to close the mold before injecting the hot liquid plastic. Once the plastic cools and hardens, it’s just a matter of extracting the molded plastic part. A two-step process they’re using to make these buttons that go on the steering handle of a jet ski.

First they mold a structural base out of hard white plastic, then they put the bass into a second mold and inject a rubber like gray plastic, this softer plastic covers everything but the raised lettering giving the button a softer feel. Factories also make molds for aluminum injection and rubber injection among other materials, they build those molds from different types of metal but using the same techniques.