Injection blow molding is famous for producing plastic bottles and hollow components. It is extensively completed in the pharmaceutical, cosmetics, and meal packaging industries. This machine guarantees precision, consistency, and overall performance in manufacturing. Businesses rely on hollow plastic product manufacturing as it produces exceptional products with minimum waste. This text will teach about injection blow molding, the materials used, and the different types and packages.

What is Injection Blow Molding?

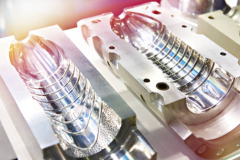

One technique for growing hollow plastic gadgets is injection blow molding. It blends blow molding and injection molding strategies. First, the plastic molding process is melted and successfully appropriately injected right into a mould to form a preform, a small plastic form that looks like a check tube. This preform is transferred to a blow mould, in which compressed air expands into the final shape. The product is then cooled and ejected from the mold.

This method is appropriate for making lightweight, long-lasting, and specific bins. It gives first control over wall thickness and consistency. Production is fast and inexperienced because the whole technique is in a single device.

What Materials Are Used in Injection Blow Molding?

Injection blow molding works with many types of plastic. The desire for clothes is based upon the software program and required homes. Some of the most customarily used materials embody:

Polyethylene (PE): This fabric is lightweight, mild, and moisture-resistant. Typically, it applies to food packing containers and bottles.

Polypropylene (PP): PP is regularly utilized in beauty and medical packaging and is famous for its strength and resistance to warmth.

Polyethylene Terephthalate (PET): PET is preferred for beverage bottles and pharmaceutical packaging bins because it is far more robust, smooth, and recyclable.

Polyvinyl Chloride (PVC) is an environmentally acceptable, long-lasting plastic in clinical programs and enterprise organization packaging.

Each material has precise benefits, and manufacturers pick the proper one based virtually primarily on product requirements.

Different Types of Injection Blow Molding

There are 3 most critical kinds of injection blow molding, every suitable for excellent applications:

Standard Injection Blow Molding (IBM) is the most unusual type of plastic bottle. It can be made of small, lightweight plastic, ensuring uniform wall thickness and unique dimensions.

Injection Stretch Blow Molding (ISBM): This method is mainly used for PET bottles. The preform is stretched in advance rather than being blown into form so that you can grow its strength and clarity.

Injection Blow Molding with Multi-Layer Technology: Some producers use more than one layer of plastic to decorate barrier houses. This method benefits packaging meals and remedies that need more air and moisture protection.

Each type has its benefits, depending on the product’s desires.

What Are the Applications of Injection Blow Molding?

Blow molding applications are widely used throughout many industries. Some not-unusual packages embody:

Pharmaceutical Packaging: Medicine bottles and tablet containers are regularly made using injection blow molding because they require precision and uniformity.

Cosmetic and Personal Care Products: Shampoo bottles, lotion packing containers, and unique beauty product packaging reveal this method’s clean and polished appearance.

Food and Beverage Packaging: PET juice, water, and soda bottles use thermoplastic molding techniques for their readability and strength.

Medical Supplies: Items like dropper bottles and exclusive sterile plastic containers are produced with this device.

Household and Industrial Products: Many cleansing product bottles and chemical boxes are made with this technique.

Thanks to its versatility, injection blow molding performs a key characteristic in modern-day manufacturing.

How Does Injection Blow Molding Differ from Extrusion Blow Molding?

Injection blow molding and extrusion blow molding furthermore appear comparable. However, they have got key variations. In injection blow molding, plastic is first injected into a mold to shape a preform. This preform is then blown into its very last shape. This way permits the manipulation of the thickness and precision of the product.

Extrusion blow molding includes melting plastic and extruding it into a tube-like form called parison. The parison is clamped into a mold and inflated to shape the last product. While extrusion blow molding is quicker, better, and lovely for large bins, it no longer provides the same level of precision as Injection stretch blow molding.

Is Injection Blow Molding Cost-Effective?

Yes, injection blow molding is cost-effective, particularly for high-volume production. Manufacturers can produce regular products without defects since it ensures minimum cloth waste and specific management. The preliminary setup cost for molds can be excessive, but the lengthy period advantages, collectively with decreased cloth utilization and automation, make it bright funding.

Additionally, the tool is inexperienced, decreasing manufacturing time and complex work expenses. Companies that require uniform and notable plastic products often find Injection blow molding machines a great choice.

Which is the China Top Plastic Injection Mold Manufacturer?

One of China’s top plastic injection mould producers is EX MOULD Co. With over 10 years of revel; EX MOULD Co is a leader in custom injection molding. The company offers expert plastic injection mould offerings, consulting, designing, prototyping, and production.

EX MOULD Co focuses on the best plastic mold-making for numerous industries. Their approach includes great plastic molded additives, custom prototypes, and rapid injection molds. They provide both low-volume and mass manufacturing at cost-effective expenses.

EX MOULD Co is an incredible choice if you need a reliable producer. They assure 100% accuracy on all injection molds. Send them your drawings and recent inquiries to get a quote for your custom plastic product.

Key Takeaways

Injection blow molding is a powerful and unique technique for generating hollow plastic products. It uses materials like PE, PP, PET, and PVC to create quite some packaging answers. With 3 critical types—IBM, ISBM, and multi-layer molding—producers can select the high-quality method for their dreams. This tool is considerably applied in pharmaceutical, food, beauty, and business applications.

Compared to extrusion blow molding, injection blow molding offers better precision and fabric everyday overall performance. It is likewise cost-effective for excessive quantity production; for organizations seeking out a trusted plastic injection mold manufacturer, EX MOULD Co stands proudly as the best preference in China. With their facts and determination to be satisfactory, they provide top injection molds that meet global necessities.