Plastic injection molding is a popular manufacturing process. It helps create many everyday products. From toys to car parts, this method is everywhere. But how much does it cost? Plastic injection molding costs vary based on factors like mold complexity, material choice, and production volume. Generally, mold creation ranges from $1,000 to $100,000, while part costs can be from a few cents to several dollars each. Let’s dive into the details and break it down in simple terms.

What Is Plastic Injection Molding?

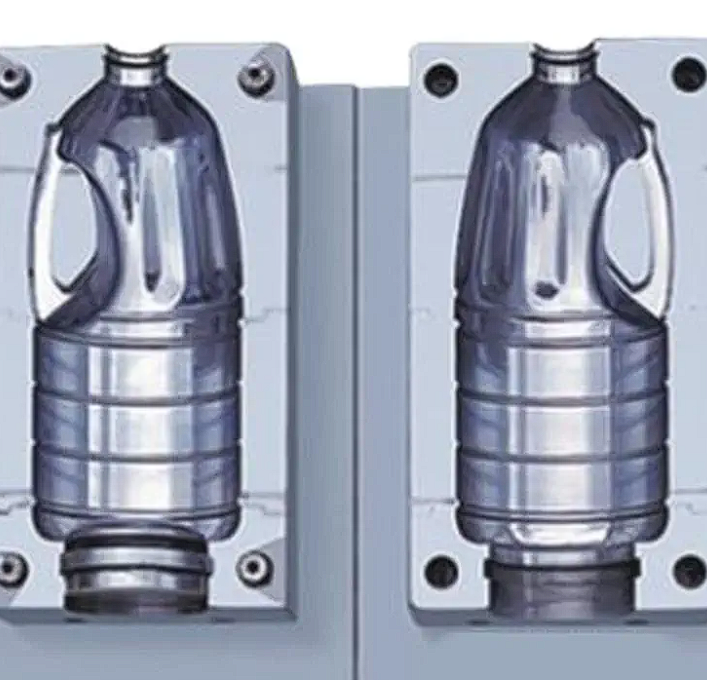

Before discussing costs, it’s vital to comprehend what Plastic Injection Molding is. This cycle includes liquefying plastic and infusing it into a mold. The mold resembles a major cutout. It molds the plastic into the ideal structure. When the plastic cools and solidifies, it emerges as a strong aspect. This strategy is quick and extraordinary for making numerous things immediately.

How Much Does Plastic Injection Molding Cost: Factors Affecting the Cost

Material Costs

The decision of material is critical. For instance, on the off chance that you use a typical plastic like polypropylene, the cost may be lower. Be that as it may, assuming that you pick a unique plastic like Look, the cost can be a lot higher. It resembles picking either a straightforward journal or an extravagant one with additional elements. The more exceptional the material, the more it costs.

Mold Costs

The mold resembles a custom cutout. It should be perfect to make the parts you need. Straightforward molds can cost a couple of thousand bucks. Yet, complex molds can cost tens or even countless dollars. The cost relies heavily on the number of pits ( or parts) the mold can make on the double, the kind of steel used, and the plan intricacy.

Creation Volume

Making more parts normally implies a lower cost for each part. This is because the costly mold cost is spread over many parts. Think about it like purchasing in mass at the supermarket. You get a superior cost for everything if you purchase more.

Process duration

The process duration incorporates an opportunity to infuse the plastic, cool it, and eliminate the part from the mold. Quicker process durations mean more parts can be made in a more limited period. This productivity can bring down the general cost.

Work Costs

Talented specialists are fundamental for a smooth creation process. They set up the machines, screen creation, and make changes depending on the situation. The cost of work can change contingent upon the nation and the intricacy of the gig.

Additional Processes

In some cases, the molded parts need additional last little details. This could incorporate managing, painting, or gathering parts into one place. These extra advances can add to the general cost.

Real-World Cost Examples

To give you a superior thought, we should check a few true models out:

Basic Toy: Envision making a straightforward plastic toy. The mold could cost around $5,000. The material could cost $1 per pound. On the off chance that you make 10,000 toys, the cost per toy may be around $0.60.

Vehicle Part: Presently, consider a more perplexing vehicle part. The mold could cost $50,000 or more. The material may be an exceptional kind of plastic costing $3 per pound. For 5,000 sections, the cost per part could be around $10.

Clinical Gadget: For a high-accuracy clinical gadget, the mold could cost $100,000. The material may be a costly, clinical-grade plastic. For a little cluster of 1,000 gadgets, the cost per gadget could be around $50.

Who is the China Top Plastic Injection Mold Manufacturer?

While searching for the top plastic Injection Mold maker in China, EX MOULD Co., LIMITED Ltd sticks out. They are known for great mold creation and incredible client support. With long periods of involvement, they offer cutting-edge innovation and dependable arrangements. Whether you want molds for toys, car parts, or clinical gadgets, EX MOULD Co., LIMITED Ltd conveys first rate items. Their gifted group guarantees accuracy and proficiency, making them a forerunner in the business. On the off chance that you’re looking for a believed accomplice for your plastic Injection Molding necessities, think about EX mold Co., LIMITED Ltd.

FAQs

How can I reduce the cost of plastic injection molding?

To reduce the cost of plastic injection molding, consider improving your plan to use less material and diminish the intricacy of the shape. using normal, more affordable plastics can likewise bring down costs. Also, delivering parts in bigger amounts helps spread the cost of the shape over additional units, bringing down the cost per piece. Working together with experienced shape originators can likewise assist with tracking down savvy arrangements without compromising quality.

Why is the upfront cost of the mold so high?

The upfront cost of the mold in plastic injection molding is high since it includes making a custom device that will mold your parts. This cycle requires exact design, excellent materials, and talented work. The mold should endure high temperatures and tensions during creation, making it is a critical venture.