Plastic moulds are very important in making everyday items. These moulds shape melted plastic into different forms. From toys to car parts, plastic moulds are everywhere. There are many types of plastic moulds, each with its special use. Let’s explore these types and understand how they work.

Many Types of Plastic Mould

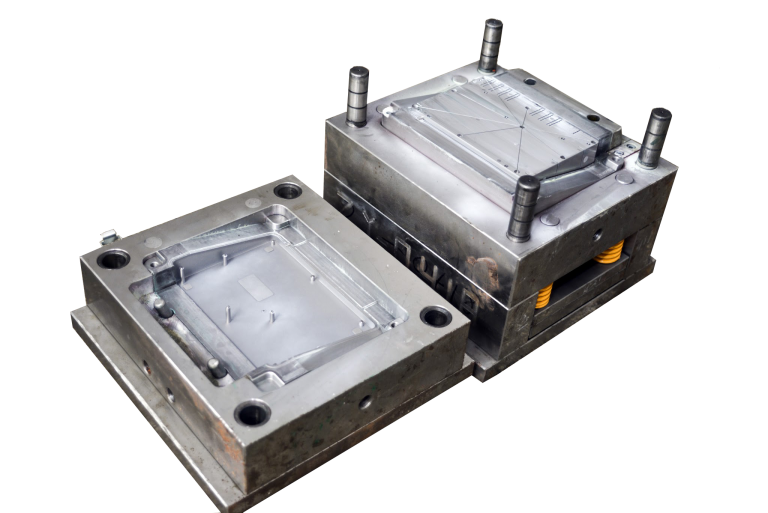

Injection mould

Injection shaping is one of the most widely recognized types of plastic molds. In this strategy, liquefied plastic is infused into a shape. The plastic cools and solidifies into the state of the shape.

How It Functions:

- Warming: Plastic pellets are warmed until they dissolve.

- Injection: The dissolved plastic is infused into a mould using high strain.

- Cooling: The mould is cooled so the plastic solidifies.

- Discharge: The mould opens and the molded plastic part is shot out.

Uses: Injection shaping is used to make toys, bottle covers, and numerous family things. It’s perfect for making bunches of a similar thing rapidly and inexpensively.

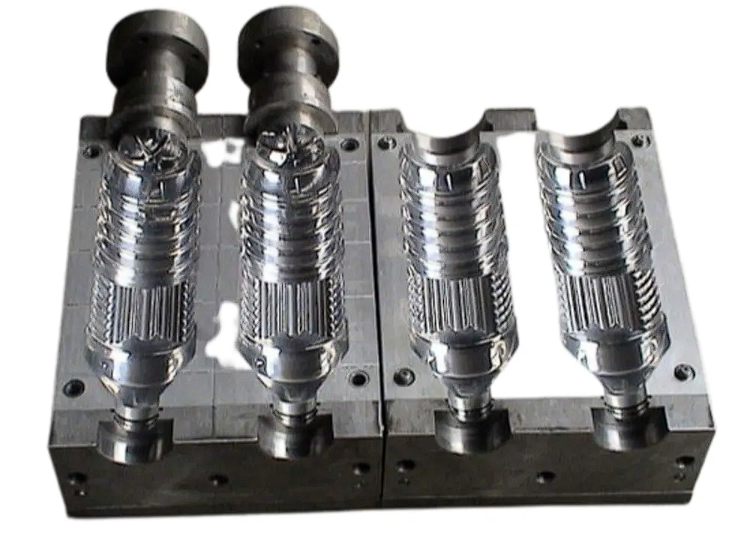

Blow Moulding

Blow shaping is used to make empty plastic things. This interaction is ideal for jugs, holders, and comparable things.

How It Functions:

- Softening: Plastic is liquefied and framed into a cylinder called a “parison.”

- Blowing: Air is blown into the parison, growing it to fit the mould.

- Cooling: The plastic cools and solidifies looking like the mould.

- Launch: The shape opens and the empty thing is taken out.

uses: Blow shaping is used for making plastic containers, gas tanks, and other empty items.

Compression Moulding

Compression Moulding is used to make huge and solid plastic things. This technique uses intensity and strain to shape the plastic.

How It Functions:

- Position: A piece of plastic is set into a warm shape.

- Pressure: The mould is shut, and pressure is applied to shape the plastic.

- Cooling: The shape is cooled, and the plastic solidifies.

- Discharge: The shape opens, and the thing is taken out.

uses: Pressure shaping is used for vehicle parts, huge holders, and electrical parts.

Rotational mould

Rotational Moulding makes empty things by pivoting a mould. This interaction guarantees even dispersion of plastic.

How It Functions:

- Stacking: Plastic powder is put in a mould.

- Warming: The mould is warmed and pivoted this way and that.

- Covering: The dissolved plastic covers within the mould equitably.

- Cooling: The mould is cooled, and the plastic solidifies.

- Discharge: The mould opens, and the empty thing is taken out.

uses: Rotational mould is used for making enormous empty items like tanks, jungle gym gear, and kayaks.

Extrusion Moulding

Extrusion Moulding makes long persistent shapes like lines and sheets. This technique pushes dissolved plastic through a bite of the dust to shape it.

How It Functions:

- Softening: Plastic pellets are dissolved.

- Expelling: The softened plastic is pushed through a bite of the dust to frame a long shape.

- Cooling: The plastic cools as it leaves the pass on.

- Cutting: The consistent shape is cut into wanted lengths.

uses: Expulsion shaping is used for making lines, sheets, and plastic movies.

Thermoforming

Thermoformingshapes plastic sheets by warming and extending them over a mould. This strategy is perfect for making enormous, dainty things.

How It Functions:

- Warming: A plastic sheet is warmed until it turns out to be delicate.

- Shaping: The delicate sheet is extended over a mould using a vacuum or strain.

- Cooling: The plastic cools and takes the state of the shape.

- Managing: The abundance of plastic is cut back.

uses: Thermomoulding is used for making bundling, plate, and auto parts.

Transfer Moulding

Transfer Moulding is like pressure moulding yet uses a chamber to preheat the plastic before it enters the mould. This strategy is used for additional complicated shapes.

How It Functions:

- Preheating: Plastic is preheated in a chamber.

- Moving: The preheated plastic is moved to a shape.

- moulding: The shape closes and shapes the plastic under tension.

- Cooling: The plastic cools and solidifies.

- Launch: The mould opens, and the thing is taken out.

uses: Move shaping is used for making electrical parts and perplexing things.

Reaction Injection Moulding (RIM)

Reaction Injection Moulding (RIM) includes blending two fluid plastics that respond and extend to fill a mould. This technique makes lightweight and solid parts.

How It Functions:

- Blending: Two fluid plastics are combined as one.

- Infusing: The blend is infused into a shape.

- Responding: The blend responds and extends to fill the mould.

- Cooling: The plastic cools and solidifies.

- Launch: The mould opens, and the thing is eliminated.

uses: Edge is used for making vehicle guards, dashboards, and other lightweight things.

Where to Buy the Best Plastic Mould?

On the off chance that you want the best plastic shape, you can visit moldplasticinjection. They are the top provider of top-notch plastic molds. Whether you are making toys, jugs, or vehicle parts, moldplasticinjection has the ideal shape for your requirements.

Their items are strong and exact, guaranteeing you come by the best outcomes without fail. Additionally, their group is amicable and prepared to assist you with tracking down the right mould. You can trust moldplasticinjection to convey first-class items rapidly and at extraordinary costs.

In this way, when you want the best plastic molds, pick moldplasticinjection. They make it simple to get the quality and administration you merit.

Final Words

There are many kinds of plastic moulds, each with its extraordinary use. From Injection Moulding to multi-shot Injection moulding, these strategies assist with making the things we use consistently. Understanding these kinds of molds assists us with valuing the innovation behind plastic items in our lives. Whether making a basic toy or a perplexing vehicle part, plastic mould plays a vital part in assembling.