Plastic bottles are used everywhere, from storing water and beverages to packaging shampoos and cleaning products. Businesses want reliable plastic bottle molding services to meet their packaging dreams. But with such severe alternatives available, how do you select the right one? We’ll help you know what plastic bottle molding is and what factors not to forget while deciding on the quality company for your goals.

What Is Plastic Bottle Molding?

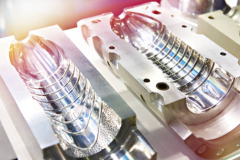

Plastic bottle molding is the process of shaping plastic into bottles of various sizes, shapes, and designs. The technique starts with uncooked plastic material, often pellets or resin. These materials are melted down and molded into bottles using a specialized device.

There are precise styles of PET bottle manufacturing strategies. One well-known technique is blow molding, which incorporates blowing air into liquid plastic to make a plastic bottle. Another Blow molding procedure for bottles is injecting the plastic right into a mold to mold the bottle’s form. These strategies make sure that bottles are long-lasting and lightweight.

How Do I Choose the Right Plastic Bottle Molding Service?

Selecting the proper plastic bottle molding industry is essential for your business. An honest company can provide fantastic bottles, meet your layout requirements, and ensure inexperienced production. Here’s what to don’t forget:

First, I will look at the organization’s experience. A service with years of experience will likely have the expertise to handle your requirements. Experienced providers recognize how to deal with precise materials, molds, and annoying production conditions.

Second, keep in mind the available customization options. Your bottles want to inform your logo’s format and functionality goals. Whether you need precise shapes, custom shades, or specific trademarks, ensure the corporation offers those alternatives.

Next, compare the production capability. If your employer wants large portions of bottles, choose an agency that is prepared to cope with bulk orders without compromising remarkably. Ask about their production tempo and functionality to satisfy time limits.

Quality assurance is a very different key element. You probably need long-lasting bottles every day, mainly if they’re used for meals or drinks. Check if the business organization necessities and gives fantastic trying out for their products.

Lastly, consider cost-effectiveness. While you shouldn’t compromise on quality, finding a business that offers competitive pricing is essential. Compare prices from more than one group to make an informed decision.

Benefits of Using Plastic Bottle Molding Services

Injection molding for plastic bottle offerings provides numerous benefits for organizations. One of the principal benefits is customization. These services allow companies to layout bottles that align with their branding. You can choose precise shapes, sizes, and sun sunglasses to make your products stand out on the cabinets.

Another advantage is price effectiveness. Producing bottles in bulk through a molding corporation often reduces production prices. Advanced molding strategies ensure a super deal, a top deal, and plenty less fabric waste, saving coins while protecting the environment.

Efficiency is likewise a significant advantage. Plastic bottle production techniques offerings use modern machines that produce bottles briefly and continuously. This is right for companies that need massive portions of bottles in a brief time frame.

Durability is one specific reason agencies depend on the company’s offerings. The bottles produced are sturdy, lightweight, and resistant to leaks, ensuring your products will eventually endure transport and storage.

In addition, many molding offerings provide sustainable alternatives. These alternatives use recyclable materials and inexperienced practices, which is best for companies that want to lower their environmental impact.

Can Plastic Bottle Molding Services Handle Large Production Volumes?

Yes, maximum plastic bottle molding services are designed to cope with significant production volumes. They use superior devices and automatic strategies to ensure fast and ordinary production. This is especially useful for groups in industries like liquids, cosmetics, and cleaning products, where the high call is not unusual.

Before choosing an organization, ask about its production ability. The right industrial company agency may be capable of meeting your present-day dreams while having the functionality to scale up as your agency grows. They also need structures in the area to preserve the best manipulation, notwithstanding that it generates enormous quantities.

Large-scale production frequently comes with the delivered gain of rate economic financial savings. Bulk orders generally charge an outstanding deal much less for every unit, making it a thoughtful desire for organizations that must govern their budgets efficiently.

Are Custom Designs Available for Plastic Bottle Molding?

Yes, custom designs are a great feature provided with the valuable, helpful resource of custom bottle mold design services. Whether you want an exact bottle form or a particular logo coloration, a notable company can supply your imaginative and prescient lifestyles.

Customization goes beyond the shape and shade of the bottles. You can also pick precise finishes, like matte or smooth textures. Some offerings even offer embossing, permitting your emblem or logo name to be part of the bottle’s format.

When discussing custom designs, communicate your needs clearly with the service provider. Share records of your brand identification and the functionality you require inside the bottles. For example, if your bottles will shop for food or drinks, they must meet safety necessities.

Customized bottles can help your products stand out. They offer your logo a professional look, making it much less complicated for customers to recognize your products on store cabinets.

Superior and Cost-Effective Plastic Bottle Molding Services

Plastic bottle molding (additionally called plastic bottle molding) is one of the plastic injection molding services supplied with the valuable resource of using EX MOULD. With contemporary high-volume bottle molding machines, we ensure particular tolerances and correct formation ultimately of the molding technique. Our superior blow molding techniques make us the proper choice for producing great bottles, and EX MOULD is proud to be a trusted plastic bottle manufacturer.

Why Choose Our Plastic Bottle Molding Services?

- Flexible and Customizable Designs: We provide tailor-made production plans to satisfy your necessities.

- Premium Materials and Competitive Pricing: We use pinnacle-grade materials, ensuring remarkably high quality at rate-effective charges.

- Versatile Material Options: You can choose from HDPE, PP, PET, Polyester, Co-polyester, Urethane, Polyurethane, and similar materials for your bottles.

- Prototypes and Full Production Runs: We can protect you whether you want a small batch of prototypes or a large-scale production run.

- Experience You Can Trust

With giant revel in and facts in eco-friendly plastic bottle production, we undoubtedly supply healthy bottles for your mission dreams. Our employer is ready to assist whether you require prototypes or large-scale output.

Request a quote today or contact EX MOULD CO. to learn more about our complete-service plastic bottle injection molding solutions for your specific packages.