Cold runner system and hot runner system are two ways to process plastic products by plastic injection mold process. Before mold manufacturing, we should consider the plastic material, performance and product quality of plastic products, so as to choose whether to use cold runner or hot runner, or both. Each of these systems has their own benefits and limitations which make them better suited for specific applications. The following article will cover the characteristics, pros & cons of both systems and detail the difference between hot runner & cold runner mold, helping you determine the most feasible option for your unique application.

What Is Hot Runner Mold

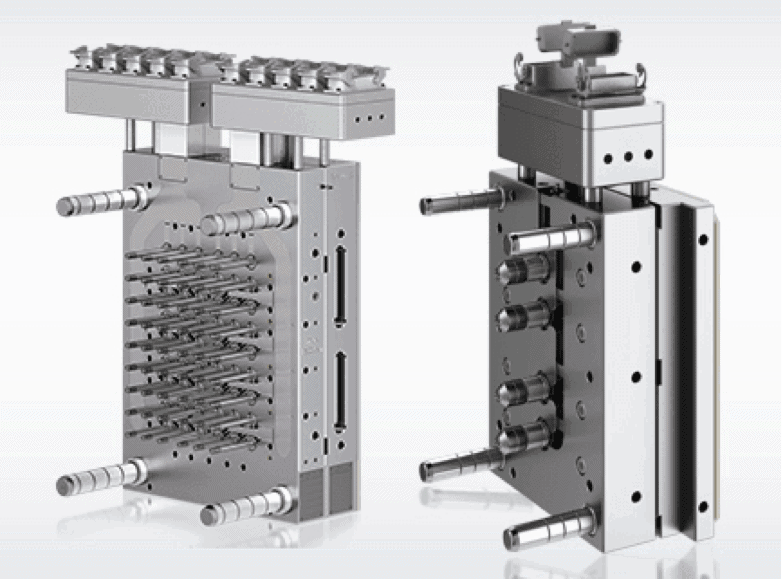

As a common part of the plastic injection molding system, the hot runner ensures that the plastic material in the runner and gate keeps the molten state by heating. Since the heating rod and the heating ring are arranged near or in the center of the runner, the whole runner – from the nozzle of the injection molding machine to the gate – is kept in a high temperature status, so that the plastic in the runner is kept molten. Usually, it is unnecessary to open the runner to remove the sprue after shutdown.

The hot runner system is generally divided into fully hot runner and semi hot runner. The design of fully hot runner is complex, but the effect is good and the maintenance cost is very low. The structure of semi hot runner is simple, stable and easy to use, and the failure rate is low. Because of the simple structure, the maintenance cost is low, which guarantees the stability of production.

Pros Of Hot Runner Injection Molding:

● No waste, save materials, save resources and costs.

● It has good fluidity at low temperature and good thermal stability at high temperature.

● Sensitive to pressure. It does not flow under pressure, but flows immediately after pressure is applied.

● Expand the application scope of injection molding process.

● Good thermal conductivity. Fast heating, fast cooling.

● Shorten the molding cycle and improve the machine efficiency.

Cons Of Hut Runner Injection Molding:

● The heat loss is serious and difficult to control.

● Serious thermal expansion will occur after heating.

● The high price of hot runner system leads to the increase of mould manufacturing cost.

● It will take a period of time for the hot runner process to be stable, resulting in more waste products at the beginning.

● In case of melt leakage and heating element failure, the product quality and production schedule will be greatly affected.

What Is Cold Runner Mold

The cold runner injection mold is a kind of mold which is demoulded together with the cold well and the gate and the mold cavity products after solidification. Cold runner molds usually consist of two or three plates that are held within the mold base. The molten thermoplastic is first injected into the mold from a nozzle via the sprue, which fills the network of runners that lead to the mold cavities. In this system, the runners are unheated and act as a delivery system that distributes the molten plastic to the individual molding cavities. The cold runner system subsequently cools the sprue, runner, and gate along with the molded part.

Pros Of Cold Runner Injection Molding:

● It is easy to use and can meet some aesthetic requirements.

● It can reduce the injection to transparent acrylate or polycarbonate used for light transmission and avoid the visible band effect caused by injection in some parts.

Cons Of Cold Runner Injection Molding:

● In the process of injection filling, due to the continuous loss of heat at the front end of the material flow, the surface of the material flow will solidify, and the injection pressure loss is large, which directly affects the service life of the injection molding machine.

● Because of the production of cold runner mold, the factory needs to set up special waste secondary processing equipment, resulting in the waste of manpower, material resources and materials.

● Some mold structures have the problem that the gate and plastic products can not be separated automatically, so the gate trimming process is needed, and the degree of automation is low.

● Mold cooling time is long, filling time is long, resulting in low production efficiency.

Cold Runner Vs Hot Runner Mould – Which Is Better For Your Injection Mold Parts?

For a long time, the cold runner has been used in the pouring system of plastic mold to inject the molten plastic into the mold cavity. With the development of science and productivity, people begin to realize that there are many disadvantages in cold runner injection mold. With the emergence of 3D software, the structure of plastic injection mold products are more and more complex, and the requirements are higher and higher. Therefore, the traditional cold runner mold in the molding process has been difficult to meet the needs of modern products, people have to consider other technology. In the 19th century, the hot runner injection molding technology was invented, which set off a revolution in the mold industry. Especially in recent years, with the development of microelectronics technology, the hot runner system has developed to a very mature stage.

The hot runner has now become the transmission system in the injection mold of thermoplastic, which is mainly designed for the production of large and long process products. Sometimes the cost is higher than the price of injection molding machine, but the productivity after investment is higher, and the raw material cost of processed products is lower. For small and medium-sized products, we mostly choose cold runner mold. A hybrid system (hot runner and cold runner) is often required in small-scale molding production.

Why Choose Hot Runner Mold?

Material Cost

The waste generated by the cold runner and gate is very large, especially the larger the volume of the workpiece, the more waste due to the length of the runner. Some of these wastes can be reused, some can’t be reused. Even if they can be reused, the comprehensive performance of the materials will be greatly reduced, and recycling equipment is also needed.

Production Efficiency

In the plastic mold, the thicker the product, the longer the cooling time. Because the cold runner needs to feed the multi-mode cavity or more pouring points at the same time, the thickness of the products in the cold runner is usually greater than the thickness of the injection products themselves. Because of the cooling time difference between the cold runner melt and the injection molded part, the cooling time will be shortened by eliminating the cold runner. The different mold injection time is also one aspect of using hot runner instead of cold runner. The difference in injection time is due to the additional time required to fill the cold runner. This is because the cold runner mold increases the opening/closing stroke of the injection molding machine.

The products by hot runner injection are more suitable for automatic removal of products. Because there is no interference of cold runner on product moving out, the second manual operation of injection molding can be greatly shortened or completely eliminated. Thus, the production efficiency is improved.

Product Quality

Choose hot runner plastic injection mold can effectively improve the surface quality and mechanical properties of the products, greatly improve the warpage of the thin-walled parts, and ensure the quality of the injection parts of the multi-mode cavity mold consistent.