As one of the pillar industries of China’s light industry, the growth rate of plastic industry has been maintained at more than 10% in recent years. In the plastic industry, the plastic hardware market is very active and has become a new consumption hotspot and a new economic growth point. The market prospect of plastic mould is considerable,

With the progress of processing technology and production equipment, thermoplastic / thermosetting plastic products with plastic materials as production raw materials and treated by different production and processing processes such as hollow molding are more and more widely used in different occasions of production and life. Plastic products are widely used in different industries such as light industrial machinery, agriculture, forestry and transportation.

However, because plastic products belong to high polymer, how to deal with waste plastic products has become a scratching problem. With simple landfill treatment, plastic products are difficult to decompose and pollute the soil environment. If incineration is carried out, the auxiliary materials added in the plastic production process will produce toxic and harmful gases and pollute the air environment.

It is understood that the emergence and development of recycled plastic industry is expected to solve the pollution problem of plastic products. In recent years, people have paid more and more attention to the quality of living environment, the people’s awareness of environmental protection has been continuously strengthened, and the rise of crude oil prices has promoted the price of plastic raw materials. The clean and environmentally friendly recycled plastic industry has obtained a good development opportunity. According to industry experts, through the adjustment of products and industrial structure with technological innovation, China’s recycled plastic industry has made great progress and is moving towards high quality and multiple varieties, The direction of high technology.

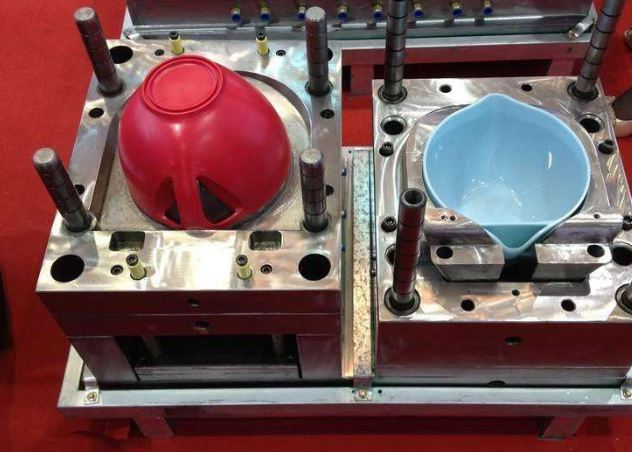

Some plastic molds in China began to replace imported products

Mold industry belongs to the basic industry of the national economy, specifically involving machinery, automobile, light industry, electronics, chemical industry, metallurgy, building materials and other industries, with a wide range of applications. With the rapid development of China’s industry, the development of automobile manufacturing, it manufacturing and medical devices has brought development opportunities to the whole mold industry.

In recent years, domestic enterprises have continuously improved mold technology and products. Therefore, some plastic molds or injection molded parts began to circulate internationally, successfully entered the supply chain system of some high-end industries, replaced some imported products and got rid of their dependence. However, it is undeniable that only a few of them have joined the international high-end market.

With the improvement of the technical level of China’s mold industry and the gradual increase of product levels, some international host industry supply chain systems are further inclined to domestic enterprises, which will be an opportunity and challenge. It is understood that by 2015, the independent matching rate of molds required by China’s market will reach more than 85%, of which the independent matching rate of medium and high-end molds will be significantly improved.

Some experts pointed out that in the future, China’s mold industry should not only continue to improve its production capacity, but also focus on the adjustment of internal structure and the improvement of the level of technological development. It mainly focuses on the professional adjustment of enterprise structure, the development of product structure towards medium and high-end molds, the improvement of import and export structure, the forming analysis and structural improvement of medium and high-end automobile panel molds, the application of multi-functional composite molds and composite processing and laser technology in mold design and manufacturing, high-speed cutting, ultra precision machining and polishing technology and informatization.