Injection molding is an extensively used manufacturing method that creates plastic products efficiently and precisely. It’s the go-to choice for industries, making everything from ordinary devices to specialized factors. But the query remains—can PLA plastic be injection molded? The solution is sure! Biodegradable plastic molding, or polylactic acid, is a plastic that plays correctly in injection molding techniques. We’ll communicate how PLA suits this method, why it’s used, its benefits, the polylactic acid manufacturing system, and the way to decide if PLA is the right desire for your assignment.

What Is PLA Injection Molding, and Why Is It Used?

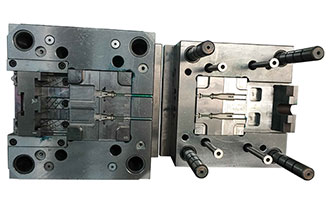

PLA injection molding involves melting PLA pellets into a liquid country and injecting them properly into a mildew to create various shapes and designs. Once the material cools and solidifies, it takes on the famous shape. This way is renowned because of PLA’s precise houses and alignment with sustainability goals.

PLA is a biodegradable and green cloth derived from renewable assets like corn starch and sugarcane. Unlike traditional plastics derived from fossil fuels, PLA decomposes over time, decreasing environmental waste. This makes it ideal for groups and industries aiming to lower their ecological impact. Typical applications for sustainable injection molding embody growing meals, packing containers, packaging, medical devices, and family items.

Benefits of Using PLA in Injection Molding Projects

There are several reasons why PLA is desired in injection molding obligations. First, it is green, which is a massive advantage for organizations seeking to adopt sustainable practices. PLA’s biodegradable nature guarantees it breaks down evidently, making it a terrific choice for environmentally conscious producers.

Second, PLA is bendy. It may be molded into numerous patterns and sizes, allowing producers to offer a vast range of products, from cups and plates to complex additives for virtual devices. Additionally, PLA is non-toxic and FDA-universal, making it appropriate for food packaging and utensils.

Another benefit is its mechanical houses. PLA gives suitable strength and sturdiness even as offering resistance to put on. It is likewise price-powerful, as it’s far lower than many different biodegradable plastics. Finally, using PLA in injection molding reduces the manufacturing tool’s carbon footprint, supporting combatting weather alternates.

PLA Injection Molding Process

The approach of eco-friendly plastic products is similar to that of different plastics; however, it requires particular care. Here’s a step-by-step breakdown:

Preparing the Mold

The first step is designing and equipping the mold. It should be made to precise measurements to ensure the final product meets the specified specifications.

Melting the PLA

PLA pellets are loaded into a PLA molded parts. The device heats the pellets until they turn into a liquid.

Injecting the Material

The molten PLA is injected into the mold below immoderate stress. This guarantees the material fills every part of the mildew.

Cooling and Solidifying

Once the mildew is crammed, the cloth is cooled. As it hardens, it takes the form of a mold.

Ejecting the Product

The completed product is eliminated from the mold. It can also go through more complete steps like trimming or sharpening.

Quality Check

The product is inspected to make sure it meets exceptional necessities. Any defects are addressed earlier than the packaging.

How Can You Determine if PLA Is the Best Choice for Your Project?

Selecting the proper material for your mission is essential for custom injection molding materials. Several elements can help you determine if PLA is an excellent preference for your needs. Start with the beneficial, valuable resource of thinking about the product’s cause. PLA is an exquisite choice if your product demands a biodegradable, inexperienced cloth.

Next, examine the sturdiness requirements of your mission. While PLA is powerful and evidence in opposition to position, it can no longer perform well under immoderate warmth or stress. If your product can be exposed to such conditions, consider the boundaries.

Cost is an exceptional problem to assess. PLA is a less costly material, but the everyday fee of molds and production must align with your fee variety. For responsibilities where lowering waste and emissions is difficult, PLA is a sustainable alternative. Additionally, tests whether PLA meets company requirements and certifications, particularly for meals-grade or scientific programs. Finally, remember the volume of manufacturing. PLA is appropriate for each small and big-scale production, making it a bendy choice for numerous needs.

Find the Best PLA Plastic Molds and Molded Parts

Finding the right provider for PLA molds and molded components is critical to completing your task. A reliable company should offer high-quality molds, precise manufacturing, and customer support. One such dependent on a name within the enterprise is EX MOULD Co.

EX MOULD is based in China and has over a decade of revel in custom injection molding. They are interested in growing exquisite plastic molded products for several industries. Their facts span from consulting and designing to prototyping and mass production. Whether you need speedy injection molds or business-grade molded factors, EX MOULD ensures constant exceptional.

Why Choose EX MOULD Co for Your PLA Injection Molding Needs?

EX MOULD has several advantages that set it apart from other companies. First, they’ve got massive know-how in the discipline. With over 10 years of experience, they have apprehended the complexities of PLA injection molding and have constantly delivered excellent outcomes.

The agency gives tailor-made answers to fulfill the suitable needs of its customers. From the initial format segment to final manufacturing, they ensure every detail aligns collectively with your necessities. Quality guarantee is a concern at EX MOULD. They guarantee 100% success in every mold and issue they produce.

Another gain of going for walks with EX MOULD is their fee-effective manufacturing method. Whether you need a small batch of prototypes or a considerable volume of finished products, they ensure affordability without sacrificing exceptionality. Their offerings cater to customers internationally, making it easy to get proper right of entry to their knowledge irrespective of who you are.

Why PLA Is a Fantastic Choice for Injection Molding

PLA is a tremendous material for injection molding because of its environmental advantages, versatility, and affordability. It lets manufacturers create sustainable products without compromising on typical performance. Renewable resource plastics are efficient, producing specific and exquisite effects.

When choosing a provider, operating with a professional business enterprise like EX MOULD ensures your challenge’s achievement. Their complete services and commitment to first-rate make them a pinnacle desire for PLA molds and molded components.

To gather the best consequences, companion with a dependable company like EX MOULD. Their information, cutting-edge methods, and superb self-control provide the assistance you need to supply your mind to life. Whether you’re beginning today’s task or enhancing a modern one, PLA and EX MOULD are winning aggregate.