Carbon fiber is popular for its electricity, sturdiness, and lightweight nature. But can carbon fiber be applied in injection molding? The brief answer is yes! This article will identify how carbon fiber injection molding works, its advantages programs, and why you must pick out EX MOULD CO for your next mission.

What is Carbon Fiber Injection Molding?

Carbon fiber injection molding is a gadget that joins carbon fiber materials with plastic gums to make enduring and lightweight parts. Carbon fiber is an exorbitant power-modulus fabric produced using more than 90% carbon content. It has excellent skills like corrosion resistance, excessive fatigue resistance, low thermal growth, and exquisite thermal conductivity. When combined with plastic resins, carbon fiber becomes a robust material for aerospace, automobile, and clinical tool manufacturing industries.

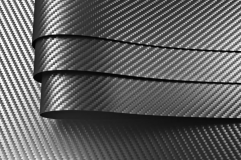

What is a Carbon Fiber Mold?

A carbon fiber mold is a device used to form carbon fiber substances into unique designs. These molds are designed to cope with the proper houses of carbon fiber, ensuring immoderate precision and an outstanding final product.

The Injection molding process with carbon fiber

Carbon fiber injection molding includes advanced molding techniques to ensure it is exquisite and accurate. Here’s a breakdown:

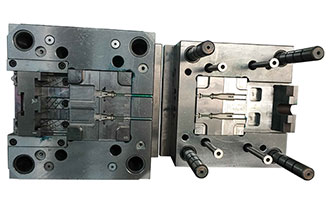

Mold education is step one. The way starts with developing a fantastic mold. The mold’s floor is polished to a replicate end, and a launch agent is achieved to ensure smooth removal of the finished product.

Layering and curing follow the steering. Carbon fiber fabric is laid into the mildew, and resin is brushed over it. The material is then cured to harden it.

Injection is the following diploma. The prepared mold is sealed and injected with resin under managed strain. Stainless metal molds regularly preserve precision in excessive stress and immoderate-temperature situations.

Heating and cooling are essential. The mildew is heated to 60°C and 120°C to ensure proper curing. Afterward, it’s miles cooled to solidify the problem.

Demolding and finishing the whole way. Once the thing is ready, it is cautiously removed from the mold. Additional methods like sharpening and inspection ensure the last product meets brilliant requirements.

Applications of Carbon Fiber Injection Molding

Carbon fiber injection molding is finished in several industries because of its unique homes. It has decided on aerospace programs in which lightweight but robust carbon fiber components are remarkable for airplanes and spacecraft.

Vehicle organizations use carbon fiber for aerospace-grade carbon fiber components to reduce weight and enhance the overall gas performance daily. In clinical tools, the sturdiness and precision of carbon fiber make it suitable for clinical devices.

In the field of tools, commercial machines use carbon fiber reinforced plastics for components that require excessive power and espresso weight. The petrochemical company has corrosion-resistant carbon fiber factors, which might be excellent for harsh chemical environments.

Advantages of Carbon Fiber Injection Molding

Carbon fiber injection molding gives numerous benefits. High electricity and sturdiness are the numerous primary benefits. High-strength carbon fiber molds are alternatively robust and can face up to heavy masses without breaking.

The lightweight nature of carbon fiber is a terrific advantage. Despite their electricity, carbon fiber elements are mild-weight, making them acceptable for applications in which weight loss is essential. Additionally, carbon fiber gives corrosion resistance, ensuring durability even in harsh environments.

Precision and accuracy are hallmarks of the injection molding method. It guarantees that every element meets unique specs. Carbon fiber’s versatility permits it to be molded into complicated shapes, making it appropriate for an oversized shape of designs.

Carbon Fiber Molding Service – Best Carbon Fiber Parts Manufacturing

EX MOULD is a trusted name for carbon fiber composite manufacturing. They have years of experience designing and manufacturing carbon fiber molds and lightweight carbon fiber parts. They use present-day devices to make sure immoderate is excellent.

The organization offers customization options. Whether you want a particular format or specific electricity parameters, EX MOULD Have you covered. Their offerings are not steeply priced without compromising on excellence, and they provide much less expensive alternatives for corporations of all sizes.

EX MOULD Follows strict first-rate management measures to ensure each element meets exceptional requirements. They charge it slowly and offer activated shipping for all orders, large or small. The corporation furthermore adheres to environmentally pleasant practices, using pure materials and ensuring no pollution.

Features of EX MOULD’s Carbon Fiber Injection Molding

When you pick out EX MOULD you can assume high mechanical power, immoderate dimensional accuracy, and stability in severe conditions. They use green materials and ensure every product meets their rigorous necessities.

Obtain as proper information as possible with EX MOULD for high-quality carbon fiber injection molding offerings. Their information, customization alternatives, and determination will make them the correct choice for your subsequent assignment. Contact them nowadays and convey your mind to existence!