As the world progresses, companies all over the globe are looking for cost-effective, reliable and efficient ways to create products. Injection molding is one such process that is used widely across multiple industries like automotive, healthcare, and consumer goods. In this post, we will be specifically focusing on the benefits of Plunger Injection Molding Machines.

Plunger injection molding machines have an edge in terms of manufacturing capabilities that the screw type machines cannot provide. Unlike the screw type, these machines have a reciprocating movement that allows for precision and control over the injection process, therefore making it a great option for small, detailed, and sensitive parts. We have listed out the top 5 benefits of using plunger injection molding machines that you shouldn’t ignore if you want to make the most out of your manufacturing process. So if you are a manufacturer or a business owner, stay tuned for what we have in store.

Types of Injection Molding Machines:

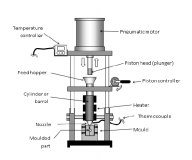

Injection molding machines are popular for their many advantages, including consistency, speed, and precision. One of the most widely used types of injection molding machines is the plunger-type machine. The plunger-type injection molding machine consists of two main parts – a plunger and a cylinder that has a screw at its end.

This type of machine is used to create a variety of plastic products for consumer and industrial use, including toys and household items. The plunger is responsible for pushing the plastic material through the barrel, passing it through the diverter shuttle, and injecting it into the mold through the nozzle. With this process, manufacturers can achieve high accuracy and reproducibility consistently.

Plunger-type Injection Molding Machine:

Plunger-type injection molding machines are the most commonly used plastic injection machines in the industry. This type of machine has a piston or pump that drives the material into the mold during injection. The plunger-type injection molding machine has a straight-through passage and a plug to prevent material from flowing backward. These machines can be operated pneumatically or hydraulically and can be either horizontal or vertical.

One of the key advantages of plunger-type injection molding machines is that they offer high injection pressure and accuracy. This results in a greater level of consistency in the parts produced, which is particularly important in industries where precision is critical.

In addition, plunger type injection molding machines are well-suited for processing a wide range of materials, including thermoplastics, elastomers, and composites. They are also known for their energy efficiency, which can result in significant cost savings over time. Overall, the advantages offered by plunger-type injection molding machines make them a popular choice for a wide variety of manufacturing applications.

Screw type Injection Molding Machine:

One alternative to the more common plunger injection molding machines is the screw type injection molding machine. It works by forcing plastic material into a mold by direct fluid pressure, using a feeding device, cylinder, and a screw that moves back and forth in the injection mold. This type of injection molding machine has two chambers, one to plasticize raw material and the other to inject it.

The machine’s reciprocating screw and barrel assembly, injection nozzle, and hopper make it an efficient and effective option for injection molding. The screw type injection molding machine offers several advantages over plunger-type machines, including better temperature control, higher injection rates, and improved consistency in the molding process.

Plunger Injection Molding machine:

Plunger-Plunger Type Injection Molding Machines are one of the most commonly used types of injection molding machines. These machines consist of a gearbox, injection cylinder, and a piston or pump. They have a straight-through passage and a plug to prevent material from flowing backward during operation. Plunger Type Injection Molding Machines are comparable to screw-type machines in the plasticizing chamber and can be horizontal or vertical, semi or fully automatic.

These machines have several advantages, including their ability to process high viscosity thermoplastics, low pressure injection, and excellent repeatability. Additionally, Plunger-Plunger Type Injection Moulding Machines are highly reliable and require very little maintenance. Overall, these machines are highly versatile and are capable of producing high quality, precision parts with minimal scrap.

Conclusion:

In conclusion, plunger injection molding machines offer several advantages over other types of injection molding machines. They provide better accuracy, reduce polymer degradation, can handle high viscosity materials, offer customizable shot sizes, and reduce dead time. These advantages make plunger injection molding machines ideal for producing high-quality, precise products.

If you are looking for a reliable, efficient, and high-performing injection molding machine, consider a plunger type machine. To learn more about the different types of injection molding machines and which one is right for your needs, consult our experts.

Plastic Injection Mold Material Guide – Advantages & Applications Of 20 Common Injection Molding Materials

Plastic Injection Mold Material Guide – Advantages & Applications Of 20 Common Injection Molding Materials  Types of Injection Molding Machines – Plunger, Screw & Reciprocating Type Injection Molding Machine

Types of Injection Molding Machines – Plunger, Screw & Reciprocating Type Injection Molding Machine  10 Plastic Injection Processes – Advantages, Disadvantages, And Applications Of Plastic Injection

10 Plastic Injection Processes – Advantages, Disadvantages, And Applications Of Plastic Injection  What is Plunger Injection Molding?

What is Plunger Injection Molding?