With the increasing demand for plastic products, plastic molds have formed a huge industrial chain. From the upstream raw and auxiliary material industry and processing and testing equipment to the downstream machinery, automobile, motorcycle, home appliances, electronic communication, building materials and other application industries, the development of plastic molds will face great opportunities. In this guide, we are in depth 10 plastic injection processes, including the advantages, disadvantages, and applications.

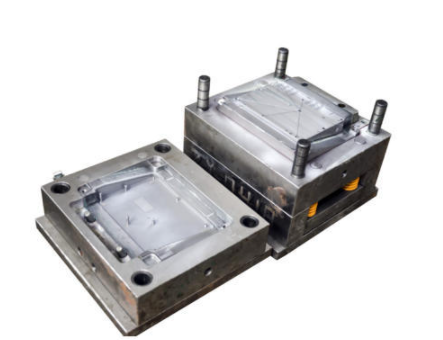

1.Injection molding

Injection molding: also known as injection molding, its principle is to add granular or powdery raw materials into the hopper of the injection machine. The raw materials are heated and melted into a flowing state. Driven by the screw or piston of the injection machine, they enter the mold cavity through the nozzle and mold pouring system, and harden and shape in the mold cavity. Factors affecting injection molding quality: injection pressure, injection time, injection temperature

Advantage:

1. Short molding cycle, high production efficiency and easy automation

2. It can form plastic parts with complex shape, accurate size and metal or non-metal inserts

3. Stable product quality

4. Wide application range

Disadvantages:

1. The price of injection molding equipment is high

2. The structure of injection mold is complex

3. The production cost is high and the production cycle is long, which is not suitable for the production of single piece and small batch plastic parts

Application:

Among industrial products, injection molded products include kitchen supplies (trash cans, bowls, buckets, pots, tableware and various containers), enclosures of electrical equipment (hair dryers, vacuum cleaners, food mixers, etc.), toys and games, various products of automobile industry, parts of many other products, etc.

Insert injection molding

Insert molding: insert molding refers to the molding method of filling pre prepared inserts of different materials into the mold, injecting resin, joining and curing the molten materials with the inserts, and making integrated products.

Process characteristics:

1. The pre-forming combination of multiple inserts makes the post-engineering of product unit combination more reasonable.

2. The mutual combination of the formability and bending of resin and the rigidity, strength and heat resistance of metal can be firmly made into complex and exquisite metal plastic integrated products.

3. In particular, the molded product can meet the basic functions of electrical products by using the combination of resin insulation and metal conductivity.

4. For the rigid molded products and the bending elastic molded products on the rubber sealing pad, after the integrated products are made by injection molding on the substrate, the complex operation of arranging the sealing rings can be omitted, making the automatic combination of subsequent processes easier.

Two color injection molding

The first mock exam is two color injection: the injection molding of the plastic with different colors into the same mold. It can make the plastic appear two different colors, and make the plastic parts present regular patterns or irregular moire patterns, so as to improve the usability and aesthetics of the plastic parts.

Process characteristics:

1. The core material can use low viscosity materials to reduce the injection pressure.

2. In consideration of environmental protection, recycled secondary materials can be used as core materials.

3. According to different use characteristics, for example, soft material is used for the skin material of thick finished products, hard material is used for the core material, or foamed plastic can be used for the core material to reduce the weight.

4. Lower quality core materials can be used to reduce costs.

5. The leather material or core material can be expensive and have special surface properties, such as anti electromagnetic wave interference, high conductivity and other materials to increase the product performance.

6. The appropriate combination of skin material and core material can reduce the residual stress of molded products and increase the mechanical strength or surface properties of products.

Micro foaming injection molding process

Micro foaming injection molding process: it is an innovative precision injection molding technology, which fills products by the expansion of pores, and completes the molding of parts under low and average pressure. The microcellular foaming process can be divided into three stages: firstly, the supercritical fluid (carbon dioxide or nitrogen) is dissolved in the hot melt adhesive to form a single-phase solution; Then, the mold cavity with low temperature and pressure is shot through the switch nozzle. Due to the molecular instability caused by the reduction of temperature and pressure, a large number of bubble nuclei are formed in the product, which gradually grow and form small holes.

3.Process characteristics:

1. Precision injection molding;

2. It breaks through many limitations of traditional injection molding, and can significantly reduce the weight of parts and shorten the molding cycle;

3. The warping deformation and dimensional stability of the parts are greatly improved.

Application:

Automobile instrument panel, door panel, air conditioning duct, etc

Nano injection molding (NMT)

NMT (nano molding technology): it is a method of combining metal and plastic with nanotechnology. After the metal surface is nano treated, the plastic is directly injected and formed on the metal surface, so that the metal and plastic can be formed as a whole. Nano molding technology is divided into two types of processes according to the location of Plastics:

1. The plastic is one-piece molding of non appearance surface

2. The plastic is integrated with the appearance surface

Process characteristics:

1. The products have metal appearance and texture,

2. The product mechanism design is simplified, making the product lighter, thinner, shorter and smaller, and more cost-effective than CNC processing.

3. Reduce production cost and high bonding strength, and greatly reduce the utilization rate of relevant consumables

Applicable metal and resin materials:

1. Aluminum, magnesium, copper, stainless steel, titanium, iron, galvanized sheet, brass;

2. Aluminum alloy has strong adaptability, including 1000 to 7000 series;

3. Resins include PPS, PBT, PA6, PA66 and PPA;

4. PPS has particularly strong adhesive strength (3000n / C ㎡).

Application:

Mobile phone shell, laptop shell, etc

2. Blow molding

Blow molding: it is a method to clamp the molten thermoplastic raw material extruded from the extruder into the mold, and then blow air into the raw material. The molten raw material expands under the action of air pressure, fits to the wall of the mold cavity, and finally cools and solidifies into the required product shape. Blow molding can be divided into film blow molding and hollow blow molding:

Film blow molding

Film blow molding is to extrude the molten plastic from the circular gap of the die of the extruder head into a cylindrical thin tube, blow compressed air into the inner cavity of the thin tube from the central hole of the extruder head, blow the thin tube into a tubular film with larger diameter (commonly known as bubble tube), and roll it after cooling.

Hollow blow molding

Hollow blow molding is a secondary molding technology to blow the rubber like parison closed in the mold cavity into hollow products with the help of gas pressure. It is a method to produce hollow plastic products. According to the different manufacturing methods of parison, hollow blow molding includes extrusion blow molding, injection blow molding and tensile blow molding.

1) Extrusion blow molding: extrusion blow molding is to extrude the tubular parison with an extruder, clamp it in the die cavity while it is hot and seal the bottom, and then inject compressed air into the inner cavity of the tube parison for blow molding.

2) Injection blow molding: the parison used is obtained by injection molding. The parison is left on the core mold of the mold. After closing the mold with a blow mold, compressed air is introduced from the core mold to blow, cool and demould the parison to obtain the product.

Advantage:

The product has uniform wall thickness, small weight tolerance, less post-processing and small waste corners; It is suitable for the production of small precision products with large batch.

3) Stretch blow molding: place the parison heated to the stretching temperature in the blow molding die, stretch longitudinally with the stretching rod, and stretch and blow laterally with the blown compressed air to obtain the product.

Application:

1. Film blow molding is mainly used to manufacture plastic thin molds;

2. Hollow blow molding is mainly used to make hollow plastic products (bottles, packaging barrels, watering cans, oil tanks, cans, toys, etc.).

3. Extrusion molding (profile)

Extrusion molding: also known as extrusion molding, it is mainly suitable for the molding of thermoplastic plastics, and also suitable for the molding of some thermosetting and reinforced plastics with good fluidity. The forming process is to extrude the heated and molten thermoplastic raw materials from the die with the required section shape by using the rotating screw, then shape them by the setting device, and then harden them through the cooler to become the product with the required section.

Process characteristics:

1. Low equipment cost;

2. Simple operation, easy process control and continuous automatic production;

3. High production efficiency; The product quality is uniform and dense;

4. Products or semi-finished products with various section shapes can be formed by changing the die.

Application:

In the field of product design, extrusion has strong applicability. The types of extruded products include pipe, film, bar, monofilament, flat belt, net, hollow container, window, door frame, plate, cable cladding, monofilament and other special-shaped materials.

4.Calendering (sheet, film)

Calendering: it is a method that plastic raw materials are connected into films or sheets under the action of extrusion and extension through a series of heated pressing rollers.

Process characteristics

Advantages: good product quality, large production capacity and automatic continuous production;

Disadvantages:

Huge equipment, high-precision requirements, much auxiliary equipment, product width, pressure extension machine roller length limit.

Application:

It is mainly used in the production of PVC soft film, sheet, sheet, artificial leather, wallpaper, floor leather, etc.

5.Press molding

Press molding: it is mainly used for the molding of thermosetting plastics. According to the properties of molding materials and the characteristics of processing equipment and process, press molding can be divided into molding and lamination molding.

Molding

Compression molding, also known as compression molding, is the main method of molding thermosetting plastics and reinforced plastics. The technological process is to pressurize the raw materials in the mold that has been heated to the specified temperature, make the raw materials melt and flow and evenly fill the mold cavity, and make the raw materials form products after a certain time under the conditions of heating and pressurization.

Process characteristics:

The molded products have dense texture, accurate size, smooth and smooth appearance, no gate trace and good stability.

Application:

In industrial products, molded products include electrical equipment (plugs and sockets), pot handles, tableware handles, bottle caps, toilets, unbreakable dinner plates (Meinai dishes), carved plastic doors, etc.

Lamination molding

Lamination forming: it is a method of combining two or more layers of the same or different materials into a whole under the conditions of heating and pressurization with sheet or fibrous materials as fillers.

Process characteristics:

The lamination process consists of three stages: impregnation, pressing and post-processing. It is mostly used to produce reinforced plastic plates, pipes, bars and model products. The texture is dense and the surface is flat and smooth.

6. Injection molding

Pressure injection molding: it is a molding method of thermosetting plastics developed on the basis of compression molding, also known as transfer molding. The process is similar to the injection molding process. During pressure injection molding, the plastic is plasticized in the feeding cavity of the mold, and then enters the cavity through the pouring system, while injection molding is plasticized in the barrel of the injection molding machine. The difference between pressure injection molding and compression molding: the compression molding process is to add materials first and then close the mold, while pressure injection molding generally requires to close the mold first and then add materials.

Advantages: (compared with compression molding)

1. The plastic has been plasticized before entering the cavity, which can produce plastic parts with complex shape, thin wall or great change in wall thickness and fine inserts.

2. Shorten the forming cycle, improve the production efficiency, and improve the density and strength of plastic parts.

3. Because the mold is completely closed before plastic forming and the flash of parting surface is very thin, the precision of plastic parts is easy to ensure and the surface roughness is low.

Disadvantages:

1. There will always be some surplus materials left in the feeding room, which consumes a lot of raw materials;

2. The finishing of gate trace increases the workload;

3. The forming pressure is higher than that of compression forming; The shrinkage is larger than that of compression molding;4.

4.The structure of the die is also more complex than that of the compression die;

5. The process conditions are more strict than the requirements of compression molding, and the operation is difficult.

7. Rotational molding

Rotational molding: firstly, the plastic raw materials are added into the mold, and then the mold rotates continuously along the two vertical axes and heats it, so that the plastic raw materials in the mold are gradually and evenly coated, melted and adhered to the whole surface of the mold cavity under the action of gravity and heat energy, formed into the required shape, cooled, shaped and demoulded, and finally obtained the products.

Advantage:

1. Provide more design space and reduce assembly cost;

2. Simple change and low cost;

3. Save raw materials.

Application:

Water polo, floating ball, small swimming pool, bicycle cushion, surfboard, machine shell, protective cover, lampshade, agricultural sprayer, furniture, canoe, camping vehicle roof and so on.

8.Drop molding

Drop molding: thermoplastic polymer materials are used to have the characteristics of variable state, that is, they have viscous flow under certain conditions and can restore the characteristics of solid state at room temperature. Appropriate methods and special tools are used to spray ink, shape them into the designed form as required under their viscous flow state, and then solidify and form at room temperature. The process flow mainly includes three stages: weighing glue, dropping plastic, cooling and curing

Advantage:

1. Good transparency and gloss of products;

2. It has physical properties such as anti friction, waterproof and anti pollution;

3. It has a unique three-dimensional effect.

Application:

Plastic gloves, balloons, condoms, etc

9. Blister molding

Blister molding: also known as vacuum molding, it is one of the thermoforming methods of thermoplastic. It refers to clamping the sheet or plate material on the frame of the vacuum forming machine, heating and softening, adsorbing it on the mold through the air channel at the mold edge with vacuum, and obtaining the formed plastic products after short-time cooling.

Process characteristics:

Vacuum forming methods mainly include concave die vacuum forming, punch vacuum forming, concave and convex die vacuum forming, bubble blowing vacuum forming, plunger push vacuum forming, vacuum forming with gas buffer device, etc.

Advantage:

The equipment is relatively simple. The mold does not need to bear pressure. It can be made of metal, wood or gypsum. It has fast forming speed and easy operation.

Application:

Widely used in food, cosmetics, electronics, hardware, toys, technology, medicine, health products, daily necessities, stationery and other industries; Disposable cup, various cup-shaped cups, etc; Culture plate, seedling plate, degradable fast food box.

10. Plastic lining molding

Plastic lining: it is a method to pour the paste plastic (plastic sol) into the mold (concave mold or female mold) heated to a certain temperature in advance, the paste plastic close to the inner wall of the mold cavity will be gelled due to heating, then pour out the paste plastic without gelling, heat treat (bake and melt) the paste plastic attached to the inner wall of the mold cavity, and then cool it to obtain hollow products from the mold.

Process characteristics:

1. Low equipment cost and high production speed,

2. The process control is simple, but the accuracy of product thickness and quality (weight) is poor

Application:

It is mainly used for high-grade car dashboard and other products with high hand feeling and visual effect requirements, plastic lined toys, etc.