11

2024.11

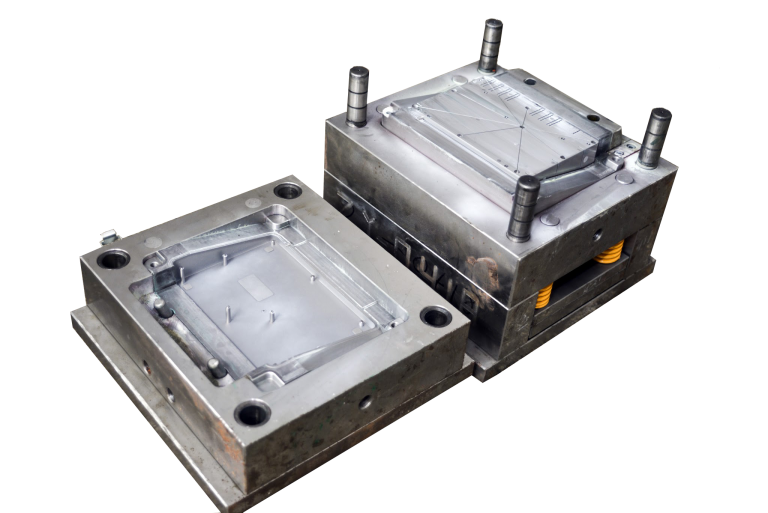

What Is Insert Molding? Process, Considerations & Applications

Insert molding is an injection molding method where steel or other non-plastic components are positioned into a mold, and plastic is injected spherically to form one stable piece. This technique combines one-of-a-kind materials in a single product, growing durable objects without using adhesives or screws. It’s an efficient technique to make merchandise stronger, lighter, and much less likely to go back aside. Let’s explore how metal insert molding works, essentia......

11

2024.11

5 Common Plastic Resins Used in Injection Molding

Injection molding is a popular gadget used to make numerous plastic items, and we consistently utilize it. This strategy comprises liquefying plastic and infusing it into a form to shape objects with extraordinary shapes. Choosing the suitable plastic resin is critical because of the truth each form of plastic is taken into consideration in all types of homes. Some are strong, a few are flexible, and a few can withstand hot temperatures. Here are 5 standard plasti......

6

2024.11

Optimizing Cooling Time for Precision and Efficiency

In injection molding, cooling time is a critical phase that impacts cycle duration, product quality, and overall production costs. With precise cooling techniques, manufacturers can achieve greater efficiency, reduce part defects, and enhance product durability. This blog explores the significance of cooling time, key factors influencing it, and techniques for optimizing the cooling process.The Role of Cooling in Injection MoldingThe cooling stage in injection mol......

4

2024.11

Benefits of Hot Runner Systems in Plastic Injection Molding

Hot runner structures are extensively utilized in Injection mold technology. They have become a popular choice for producers due to their efficiency and the high-quality consequences they produce. But what are the benefits of hot runner system in plastic injection molding? Let’s dive into why those structures are valuable and how they improve the molding process.What is a Hot Runner System?A hot runner machine keeps melted plastic hot through channels inside the m......

4

2024.11

Hot Runner vs. Cold Runner: Which Injection Mould is Best

Selecting between a hot runner system and cold-runner structures is essential when injection molding involves hot-runner molds. These structures have specific hot runner mold benefits, and each fits distinctive production desires. In this article, we’ll explore cold runner vs. hot runner, their pros and cons, and which is probably best for your needs. Let’s dive in!What is an Injection Mould Runner System?An Injection mold technology is a pathway through which me......