Importance of selecting the right material for mould tooling

Picking the right material for mould tooling is vital. It influences the item’s quality, life expectancy, and cost. How about we see the reason why this decision matters and what material is used for mould tooling?

Accuracy

The material you pick for mould tooling moulds the item’s precision. For instance, steel gives high accuracy. It catches everything about the trim interaction. This is pivotal in regions like vehicle and plane making. Here, even little deformities can lead to large issues.

Strength

The life expectancy of the mould tooling material is significant. Solid materials like solidified steel can deal with rehashed use. They don’t break down without any problem. This implies they last longer, so you don’t have to supplant them frequently. This eliminates creation stops.

Cost-Saving

Picking the right material for mould tooling can set aside cash. Great materials could cost more from the start. However, their solidarity and life expectancy frequently mean lower costs over the long haul. Likewise, materials that accelerate creation cycles can help proficiency and cut working expenses.

Manufacturability

The material you pick influences that making the product so natural. A few materials work better with specific assembling processes, similar to infusion embellishment or pressure shaping. Assuming you pick a material that fits well with your creation strategy, you can smooth out the assembling system and obtain improved results.

Climate

The material you pick for mould tooling likewise influences the climate. Materials that you can reuse or that break down normally can bring down the ecological effect of making the item. This is turning out to be increasingly more significant in our eco-accommodating world.

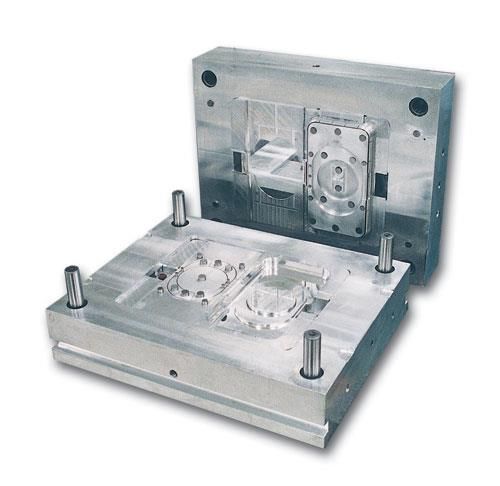

What material is used for mould tooling?

In the realm of form tooling, the decision of material is urgent. It can altogether affect the nature of the result, the proficiency of the cycle, and the general expense. We should dive into three normal materials utilized in form tooling: steel, aluminum, and tooling board.

A. Steel

Steel is a well-known decision for mould tooling because of its solidness and flexibility.

Types of Steel Used

The most regularly involved kinds of steel in form tooling are device steel and hardened steel. Apparatus steel is known for its hardness and capacity to endure high temperatures, making it ideal for molds that require accuracy and sturdiness.

Properties and Qualities

Steel’s properties make it a fantastic decision for mould tooling. It’s hard, solid, and can endure high temperatures. These qualities take into account exact forming and durable molds. In any case, steel molds can be costly and tedious to make.

B. Aluminum

Aluminum is one more typical material utilized in mould tooling. It’s lighter than steel and more straightforward to machine, making it a practical choice.

Advantages and Disadvantages

Aluminum’s primary benefit is its lightweight, which makes it more straightforward to deal with and diminishes energy costs in transportation. It likewise cools quicker than steel, lessening process durations. Nonetheless, aluminum isn’t generally so strong as steel and may not be appropriate for high-volume creation or complex mould plans.

Applications

Because of its benefits, aluminum is in many cases utilized in low to medium-volume creation. It’s additionally ordinarily utilized in model molds, where speed and cost adequacy are a higher priority than sturdiness.

C. Tooling Board

Tooling board, otherwise called displaying board, is a sort of material utilized in form tooling that offers an exceptional arrangement of highlights.

Features and Uses

Tooling sheets are not difficult to machine and give a great surface completion. They are accessible in a scope of densities and can be fortified together to make enormous models. These highlights make tooling sheets ideal for making ace models, really taking a look at installations, and composite molds.

Constraints

While tooling sheets offer many benefits, they additionally have restrictions. They are not as sturdy as metal moulds and may not be reasonable for high-volume creation. Moreover, they can be costly, particularly for huge models.

Factors Influencing Material Selection in Mould Tooling

Material choice is a basic part of form tooling. It can altogether impact the quality, proficiency, and cost-adequacy of the creation interaction. A few elements become an integral factor while picking the right material for mould tooling:

A. Cost Considerations

Cost is essential to calculate material determination. The expense of materials can shift broadly, from generally cheap aluminum to more exorbitant steel. The decision frequently relies upon the spending plan requirements of the venture. In any case, taking into account the drawn-out costs too is fundamental.

B. Complexity of the Mould

The intricacy of the mould configuration likewise impacts material choice. Complex molds with mind-boggling subtleties might require materials that can be exactly machined, like steel. Then again, less complex mould plans may not need such accuracy, taking into account the utilization of more affordable materials like aluminum or tooling board.

C. Production Volume

The volume of creation is another urgent element. For high-volume creation, sturdy materials like steel are frequently liked because of their capacity to endure rehashed use without huge wear. In any case, for low to medium-volume creation, materials like aluminum or tooling boards might be more practical.

D. Desired Surface Finish

The ideal surface completion of the eventual outcome likewise assumes a part in material determination. A few materials, similar to steel, can give an excellent surface get done with, making them ideal for items where feel are significant. Different materials, similar to aluminum, may not offer a similar degree of finish but rather could be reasonable for items where capability is a higher priority than structure.