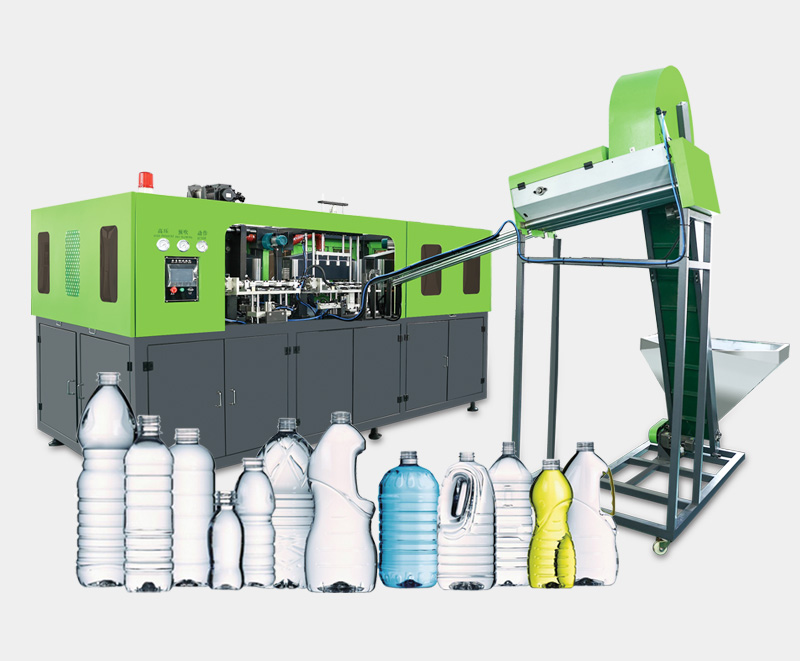

Curious about custom blow molding? It’s a personalized manufacturing process for crafting plastic products. Tailored to your designs, sizes, and needs, it’s versatile and precise. Whether you’re envisioning unique bottles, containers, or complex shapes, custom blow molding brings your ideas to life.

Engineers create molds based on your specifications, ensuring accuracy in the final product. With cost-effective mass production and material options, it’s a solution for various industries. From packaging to automotive components, this process can elevate your product offerings. Explore the world of custom blow molding and discover how it can enhance your business.

Different types of blow molding

When it comes to blow molding, you’ll find several types, each catering to different product needs. Let’s start in:

Extrusion Blow Molding: Melt plastic, form it into a tube (parison), and then blow it into a mold for items like bottles and containers.

Injection Blow Molding: Injection-mold preforms, then blow them into a mold—perfect for small bottles and medical containers.

Stretch Blow Molding: Combine injection molding and stretching for PET bottles with higher clarity and strength.

Injection Stretch Blow Molding: Similar to stretch blow molding, ideal for intricate designs, ensuring precision and high quality.

Rotational Blow Molding: Blow plastic into a rotating mold, great for large hollow items like tanks and playground equipment.

Compression Blow Molding: Place plastic between molds, then blow—suitable for specialty containers.

Coextrusion Blow Molding: Combine layers of plastic with different properties to create containers with specific attributes.

Continuous Extrusion Blow Molding: Use for long items like pipes and profiles, offering efficient production.

Accumulation Blow Molding: Accumulate molten plastic before blowing—ideal for larger parts or containers.

Reheat Blow Molding: Cool preforms, then reheat before blowing—common in PET bottle production.

A Guide To Custom Blow Molding

Custom blow molding is a manufacturing process that tailors plastic products to specific designs, sizes, and requirements. It offers versatility and precision for creating items ranging from bottles and containers to complex shapes.

Design Phase: The process begins with designing a custom mold based on the desired product specifications. Engineers create a detailed blueprint to ensure accurate results.

Material Selection: Choose the appropriate plastic material, considering factors like strength, durability, and intended use of the product.

Mold Fabrication: Craft the mold’s halves, which form the cavity for the product’s shape. Skilled professionals use computer-aided design and machining for precision.

Testing and Refinement: Before mass production, engineers create a sample mold for testing purposes. This helps identify any design or functionality issues that need refinement.

Production Setup: Once engineers finalize the mold design, they set it up in the blow molding machine. They calibrate the machinery settings for optimal production.

Blow Molding Process: We introduce molten plastic into the mold and then inflate it with compressed air. The plastic takes the shape of the mold’s cavity.

Cooling and Solidification: The plastic cools and solidifies within the mold, maintaining the desired shape and structure.

Mold Opening: We separate the mold halves and eject the formed plastic product. This step requires careful precision to avoid damaging the product.

Trimming and Finishing: We remove excess material or irregularities from the product and add any final touches.

Quality Control: The produced items undergo thorough quality checks to ensure they meet design specifications and desired quality standards.

Advantages of Custom Blow Molding:

Tailored Design: Create products with unique designs and features, catering to specific purposes and brand identity.

Cost-Efficiency: Custom molds facilitate mass production, lowering per-unit costs over time.

Consistency: Achieve uniformity in product dimensions, shapes, and characteristics.

Material Choice: Select from a variety of plastics to meet functional and aesthetic requirements.

Rapid Prototyping: Develop prototypes quickly for testing and evaluation before full-scale production.

Applications:

Custom blow molding finds applications in various industries:

Packaging: Design custom bottles, containers, and packaging solutions for different products.

Automotive: Create specialized components like ducts, reservoirs, and tanks.

Consumer Goods: Develop unique designs for toys, appliances, and household items.

Industrial: Produce parts, tools, and equipment tailored to industrial needs.

Considerations:

Design Complexity: Intricate designs may require more complex molds and production processes.

Material Properties: Choose materials that align with the product’s functionality and intended use.

Lead Time: Custom molds might have longer lead times due to design, fabrication, and testing phases.

Custom blow molding empowers businesses to create distinctive plastic products that align with their specific needs and branding, providing a competitive edge in the market.

FAQs

What is custom blow molding?

Custom blow molding crafts plastic products according to specific designs, sizes, and requirements.

What are the benefits of custom blow molding?

You get tailored designs, cost-efficiency in mass production, consistent products, and material choices.

Is custom blow molding suitable for my industry?

Yes, it’s versatile. Industries like packaging, automotive, consumer goods, and industrial applications benefit.

Final Words

Custom blow molding empowers your ideas to take plastic shape. Tailored designs, precise sizes, and specialized products become reality. With versatility and cost-effective mass production, this process caters to diverse industries. From packaging to automotive, consumer goods to industrial needs, custom blow molding shines.

It’s a gateway to distinctive products that meet your exact specifications. Elevate your brand, enhance functionality, and stand out in the market. Embrace custom blow molding as a creative and efficient solution for your plastic product needs.