Introduction

Injection mould tool manufacture is the process of creating precision tools used in the production of plastic parts. These tools, called moulds or molds, play a crucial role in shaping various products we encounter daily, from toothbrushes to car components. In this introduction, we’ll explore the key aspects of this fascinating industry.

To start, injection mould tools are custom-built to exact specifications, ensuring the final product’s accuracy and quality. Skilled engineers design these tools, taking into account material properties, part geometry, and production requirements. Once the design is finalized, expert machinists use cutting-edge equipment to craft the moulds from high-quality materials like steel or aluminum.

Precision and attention to detail are paramount in injection mould tool manufacture. Moulds must endure high pressures and temperatures, so durability is a top priority. Additionally, the moulds are meticulously maintained to ensure consistent and efficient production runs.

Design and Engineering of Injection Mould Tools

Designing and engineering injection mould tools is a crucial step in the production process. Let’s look into this fascinating world of precision and creativity!

Tool Design Considerations

Part Geometry: The shape and intricacies of the product are vital. The mould must perfectly mirror what you intend to produce.

Material Selection: Choosing the right material for your mould impacts its durability and performance. Steel or aluminum? It’s a critical call.

Cooling System Design: Think of it as the mould’s AC system. Efficient cooling ensures faster, more consistent production.

Ejection Mechanism: Getting your product out of the mould smoothly matters. A well-designed ejection mechanism prevents damage.

CAD/CAM Software in Tool Design

Computer-aided design (CAD) and computer-aided manufacturing (CAM) software are your creative partners. They let you visualize, tweak, and perfect your mould design. It’s like sculpting with precision and speed.

Prototyping and Testing

Rapid Prototyping: Before the big production run, create a quick prototype. It’s like a sneak peek. Discover flaws and make improvements early.

Tool Trial Runs: Imagine a dress rehearsal for a play. Testing your mould with real materials ensures everything works as planned. No surprises on opening night!

Manufacturing Process for Injection Mould Tools

Creating injection mould tools involves a step-by-step process, and I’m here to guide you through it!

Step 1: CNC Machining

- Material Preparation: Start with a block of steel or aluminum, the chosen material for your mould.

- Computer-Controlled Precision: CNC machines precisely cut and shape the material.

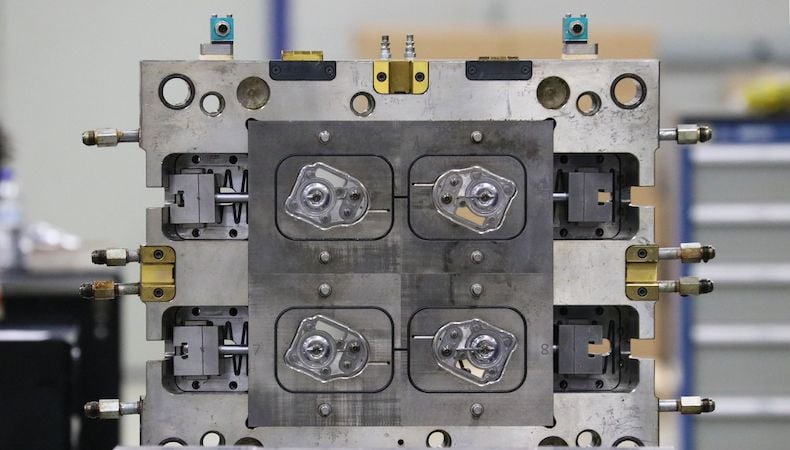

- Tool Components: Create various components of the mould like cavities, cores, and inserts.

- Tolerances Checked: Every cut is meticulously checked for accuracy, ensuring precision.

Step 2: Heat Treatment

- Strengthening the Material: Heat treatment enhances the material’s hardness and durability.

- Heating and Cooling: The material is heated and then rapidly cooled in a controlled manner.

- Optimal Strength: This process ensures the mould can withstand the rigors of production.

Step 3: Electro-Discharge Machining (EDM)

- Fine Detailing: EDM adds intricate details, holes, and fine features to the mould.

- Electrical Erosion: Controlled electrical discharges shape the material with precision.

- Surface Finish: The result is a smooth and precise mould surface.

Step 4: Polishing and Surface Finishing

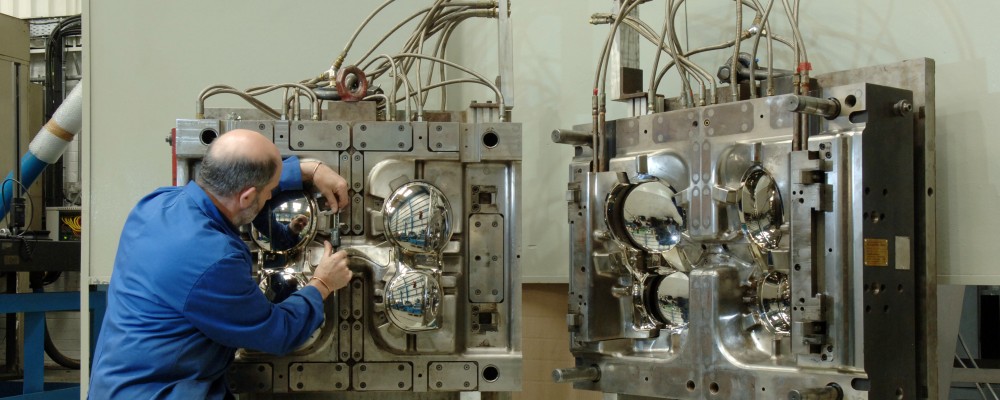

- Smooth Surfaces: Skilled technicians meticulously polish the mould’s surfaces.

- Friction Reduction: Smooth surfaces reduce friction, preventing defects in the final product.

- Mirror Finish: Achieve a mirror-like finish for flawless injection moulding.

Step 5: Assembly and Inspection

- Putting It All Together: Assemble the mould components, ensuring a perfect fit.

- Quality Checks: Rigorous inspections verify dimensions and integrity.

- Fine-Tuning: Any adjustments or fine-tuning are made to guarantee top performance.

With each step in the manufacturing process, your injection mould tool takes shape. CNC machining shapes the raw material with precision, heat treatment strengthens it, EDM adds fine details, and polishing ensures a smooth finish.

Cost Factors and Economics

In the world of injection mould tool manufacture, understanding the cost factors and economics is crucial for both businesses and individuals alike.

Cost Analysis of Injection Mould Tool Manufacture

When we talk about the cost of manufacturing injection mould tools, it’s not just about the raw materials and labor. It involves a comprehensive analysis of all expenses, including equipment, machining, heat treatment, and inspection. This analysis helps you determine the total investment required for your mould.

Factors Affecting Tooling Costs

Several factors impact tooling costs. The complexity of the mould design, the type of material used, and the size of the tool all play a role. Additionally, the production volume and the quality standards you need to meet influence costs. Understanding these factors allows you to make informed decisions and manage your budget effectively.

Return on Investment (ROI) Considerations

Calculating the ROI for your injection mould tool is essential. It helps you evaluate the profitability of your investment. Consider factors like the expected production volume, the lifespan of the tool, and the revenue generated from products made using the tool. A positive ROI is a sign that your investment in the mould tool is paying off.

FAQs

What is injection mould tool manufacture?

Injection mould tool manufacture is the process of creating precise moulds for shaping molten plastic into specific forms, crucial in manufacturing various plastic products.

What materials are used for injection mould tools?

Common materials include steel and aluminum, chosen based on factors like production volume and tool durability.

How does CAD/CAM software help in tool design?

CAD/CAM software aids in visualizing, simulating, and optimizing mould designs with precision before production.

What’s the importance of rapid prototyping in tool manufacture?

Rapid prototyping allows early identification and rectification of design flaws, reducing production issues.

How can I prolong the life of my injection mould tool?

Regular maintenance, proper cleaning, and adherence to best practices can extend a tool’s lifespan.

Final words

Injection mould tool manufacture is a fascinating blend of creativity and precision. These tools, crafted with attention to detail, drive the mass production of countless plastic products we rely on daily. From design considerations to materials, CAD/CAM software, and cost analysis, this field demands careful planning and expertise.