Repairing blow mold plastic is a practical skill that can save you money and extend the life of various items. From everyday containers to outdoor furniture, blow mold plastic is everywhere. In this guide, you’ll find step-by-step instructions on how to effectively mend cracks, breaks, or other damage in blow mold plastic.

With just a few tools and a little effort, you can restore your plastic items to their former glory. Whether you’re dealing with a toy, a bottle, or a piece of furniture, the process remains consistent. Get ready to learn the straightforward and rewarding art of blow mold plastic repair.

Can you repair a blow mold plastic?

Yes, you can repair a blow mold plastic with some simple steps. Firstly, gather your materials: sandpaper, heat gun, and plastic welding kit. Sand the damaged area gently to smooth the surface. Next, use the heat gun to soften the plastic around the damaged spot. Once it’s pliable, apply the plastic welding rod to fill and fuse the crack.

Move the rod steadily to create a strong bond. Allow it to cool and harden. If there are any excess bits, trim them carefully. After that, use finer sandpaper to blend the repaired area with the rest of the plastic. Finally, for a polished look, use a plastic polish to buff the repaired spot. With a little patience and effort, your blow mold plastic can be as good as new!

How to repair blow mold plastic?

Repairing blow mold plastic can be done step by step with attention to detail.

Step 1: Gather Materials

Collect all the necessary items before starting the repair. You’ll need sandpaper of two different grits (150-grit for initial sanding, and 400-grit for finishing), a heat gun, a plastic welding kit (available at hardware stores), a plastic welding rod that matches the type of plastic you’re repairing, safety gloves, safety goggles, a utility knife, and plastic polish.

Step 2: Safety First

Put on your safety gloves and goggles. Working with heat and plastics can release fumes, so it’s important to protect your hands and eyes.

Step 3: Assess the Damage

Carefully examine the blow mold plastic to identify the extent of the damage. This will help you plan the repair process.

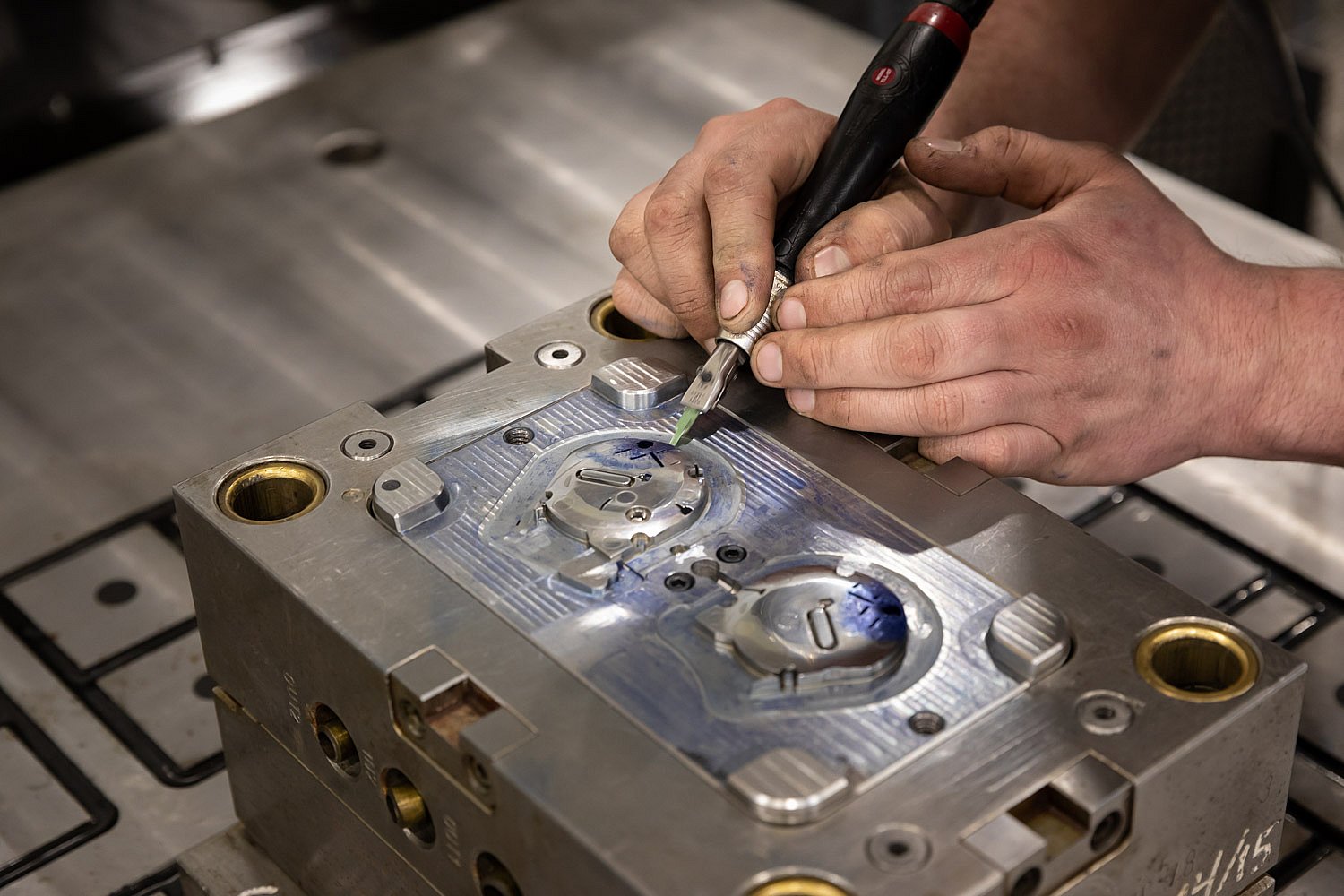

Step 4: Surface Preparation

Use the 150-grit sandpaper to gently sand the area around the damaged portion. Sanding creates a rough surface that allows the plastic welding material to adhere better.

Step 5: Apply Heat

With the safety goggles still on, use the heat gun to apply heat to the damaged area. Keep the heat gun moving at all times to avoid overheating or melting the plastic.

Step 6: Welding

Once the plastic becomes pliable under the heat, it’s time to use the plastic welding kit. Insert the appropriate plastic welding rod into the welding tip. As the plastic softens, guide the welding rod along the crack or damaged area. Move steadily to ensure proper bonding. The welding rod will melt and fuse with the plastic, forming a strong connection.

Step 7: Cooling Time

Allow the repaired plastic to cool naturally. As it cools, it will harden and solidify, ensuring a durable fix.

Step 8: Trim Excess Plastic:

After the repair has cooled, use a utility knife to carefully trim away any excess plastic or uneven edges. The goal is to make the repaired area flush with the surrounding plastic.

Step 9: Smooth the Surface

To achieve a seamless finish, use the 400-grit sandpaper to gently sand the repaired area. This step also helps blend the repair into the rest of the plastic.

Step 10: Polishing

Apply plastic polish to a clean cloth and gently buff the repaired area. This not only adds a shine to the repaired spot but also further blends it with the original plastic.

Step 11: Final Inspection

Take a close look at the repaired area. Ensure that it’s smooth, properly bonded, and matches the surrounding plastic.

Step 12: Clean Up

Once you’re satisfied with the repair, clean your tools and workspace. Properly dispose of any waste materials and keep your tools in good condition for future repairs.

By following these detailed steps, you can effectively repair blow mold plastic, giving your items a second life and saving money on replacements.

FAQs

What is blow mold plastic used for?

Blow mold plastic is versatile and commonly used for producing a range of everyday items. It’s used to make bottles, containers, toys, outdoor furniture, automotive parts, and more. The process involves inflating hot plastic into a mold, creating the desired shape.

How do I repair a crack in blow mold plastic?

Repairing a crack in blow mold plastic involves a few steps. Begin by gently sanding the damaged area to create a smooth surface. Then, use a heat gun to warm the plastic around the crack until it’s pliable. With a plastic welding kit, feed a welding rod into the welding tip and apply it along the crack, steadily moving to bond the plastic. After it cools and hardens, trim excess plastic and sand the area. Finally, polish for a seamless finish.

Can I repair outdoor blow mold plastic furniture?

You can repair outdoor blow mold plastic furniture. The repair process is similar to other blow mold plastics. Ensure to use a plastic welding rod that matches the type of plastic in your furniture to achieve a strong and lasting repair. Follow the steps of sanding, heating, welding, trimming, and finishing for a successful repair.

Can I use regular glue to fix blow mold plastic?

Using regular glue to fix blow mold plastic is not recommended. Blow mold plastics require a specific repair method known as plastic welding, which uses heat and compatible plastic materials to create a strong and permanent bond. Regular glue won’t provide the same level of strength and longevity as plastic welding. It’s best to follow the proper repair process for the best results.