Introduction

Are you gearing up for a plastic molding project? It’s an exciting journey, and one key factor you need to wrap your head around is understanding the cost dynamics. Why? Because budget planning is like having a roadmap for your project! In this extensive guide, we’re diving deep into the world of plastic mold costs, breaking down the various aspects so it’s crystal clear. From insights to handy tips and real-world experiences, we’re here to make sure you’re well-prepared for your plastic molding adventure. So, buckle up and let’s unravel the secrets of how much a plastic mold really costs!

The basics of plastic mold

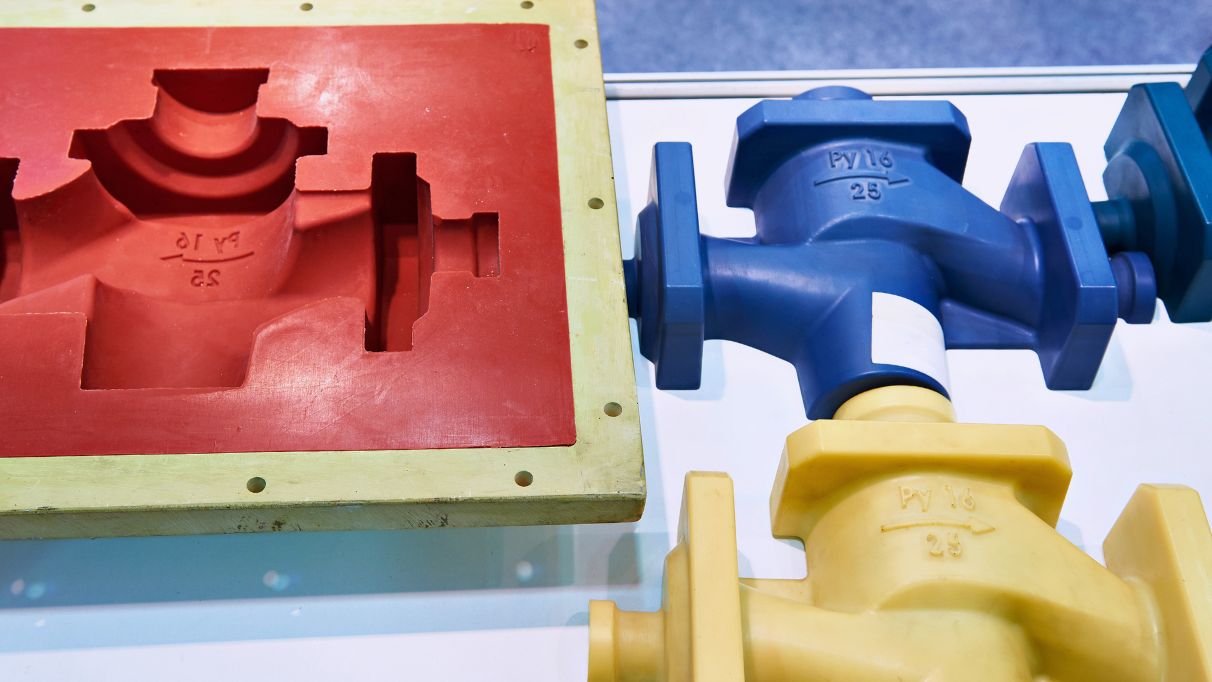

A plastic mold, often called a mold or tool, is a specialized device integral to the intriguing process of crafting plastic products through injection molding. Picture it as a precise template, consisting of two main parts known as the cavity and the core. In this enchanting dance of hot and cold, the mold is filled with molten plastic under pressure, transforming into a solid form as it cools. This magical tool unveils a variety of creations, from simple items to intricate components used across diverse industries. The artistry lies in the design and construction of these molds, determining the quality and consistency of the final plastic products. The complexity of the molds can range from simple to intricate, adapting to the specifications and production volume required. Crafted with meticulous attention to detail and durability, these molds play a pivotal role in shaping the plastic wonders we encounter daily with precision and reliability.

Factors Affecting Mold Costs

Complexity of Design: How fancy or complicated the mold looks affects how much it costs.

If the design is super intricate, it needs special tools that can be more expensive.

Size of the Mold: Think of the mold like a puzzle piece. If it’s a big puzzle piece, it needs more material and time to make, which can make it cost more.

Material of the Mold: The material used to make the mold matters.

Some materials are tougher and can be used many times, but they can be pricier.

Number of Cavities: Imagine the mold is a cookie cutter. If it cuts out more cookies at once, it’s more useful but also more complicated and costly.

Tolerance and Surface Finish Requirements: Sometimes, the mold needs to be super precise and smooth.

Making things extra perfect can take more time and effort, bumping up the cost.

Lead Time: If there’s a rush to finish the project quickly, it might cost more.

Getting things done faster can mean extra work and more resources, making it a bit more expensive.

Manufacturing Process: There are different ways to make the mold, like using special machines or tools.

Each way has its own quirks and costs, affecting how much you pay for the mold.

Working closely with a mold expert is key to figuring out the exact cost based on what you need. Even though molds cost a bunch upfront, remember, it’s a one-time payment. After that, the price for each plastic part depends on how many you make and the way you make them.

What is the best place for plastic mold?

After learning the basics and the factors that affect plastic mold,. Its time to know where the best place for plastic molding is. There are many places available for this, both offline and online but not all places are the same. You need to get the best place for the best service and we exactly know what that is. On the website of EX MOULD Co., Ltd., you can get what you are seeking. Dont worry, just go on and visit the website of EX MOULD Co., Ltd.

FAQs

How much does a plastic mold cost on average?

Plastic molds range greatly in price, from just a couple thousand to many hundreds of thousands of dollars. It depends on factors such as complexity, materials, and production volume.

Are there cost-saving measures for plastic mold production?

Yes, exploring alternative materials, optimizing design for simplicity, and negotiating with manufacturers can be effective cost-saving measures without compromising quality.

Can I use a plastic mold for prototyping?

Absolutely! Given their low price and agility, plastic molds are frequently used in testing, enabling designers to test and improve their goods and ideas.

Do higher mold costs guarantee better quality?

Not necessarily. While high-quality molds often come at a premium, thorough research and selecting reputable manufacturers are crucial for ensuring both quality and cost-effectiveness.

How does geographic location impact mold costs?

Geographic location influences labor and overhead costs. Choosing a manufacturer in a region with lower living standards may result in more affordable mold prices.

conclusion

To wrap it up, understanding plastic mold costs is like embarking on a journey where you need to know the ins and outs. Think of design complexity, material choices, and keeping an eye on what’s happening in the industry as your trusted companions. It is a game in which wise choices are essential to victory. Just remember, being good at negotiations and aware of sneaky hidden costs is like having secret weapons to make sure your plastic molding adventures turn out to be awesome!