Founded in 2006, EX MOULD Co., LIMITED Ltd’s the industry leading supplier of custom Injection Moulding from China! With over 10 years experience in manufacturing Plastic Molded Products, we provide professional Plastic Injection Mold Service from consulting, designing, prototyping, to producing, being one of the top-grade injection mold makers and manufacturers for a wide range of industries. Our injection molding process involves top-class and commercial-grade plastic end-use molded parts, custom prototypes, rapid injection molds and more, while cost and time-efficient low or mass volume production are always be provided to customers around the world! Send us your drawings and inquiry now, we will give back you 100% quality guaranteed injection molds!

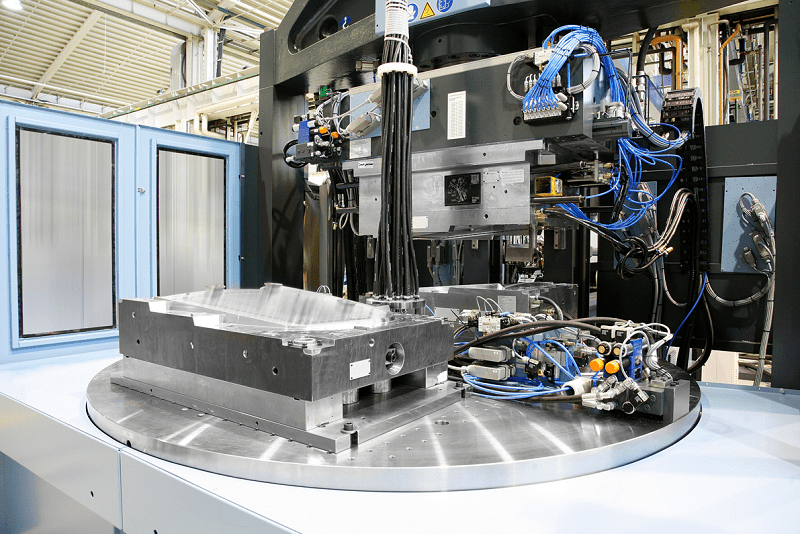

Rely on our multiple advanced machines and equipments, experienced design engineer, machinists and skilled workers, we are able to offer you the widest range of custom Injection Molding service, including Clod Runner Mold, Hot Runner Mold, Insert Mold, Epoxy Mold, Silicone Mold, Blow Mold, Resin Mold and more, also wide variety of certified materials (PLA, ABS, Nylon, PVC, Poly, Carbon Fiber, LDPE, PTFE etc.) and surface finishes are available to meet your special requirements and demands.

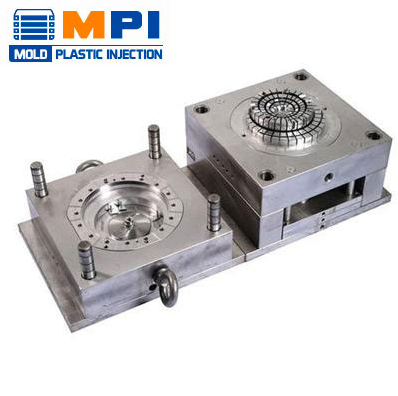

Injection molds are refers to the tooling for producing a wide variety of plastic parts. By injecting molten materials into a plastic mold to give plastic products complete structure and precise dimensions, thus plastic components are created and manufactured quickly, from plastic trinkets and toys to automotive body parts, cell phone cases, water bottles, containers and essentially many of the plastic parts that we use in every-day life. So plastic injection molding company needs high-quality plastic moldings to speed up your market you still need to make plastic molds. To achieve the flexibility in shape and size, there are many types of injection mould and tooling are designed and created, such as Hot Runner Mold, Cold Runner Mold, Blow Mold, Insert Mold, Circle Mold, Carbon Fiber Mold, Resin Mold, Silicone Mold, Over Mold and more.

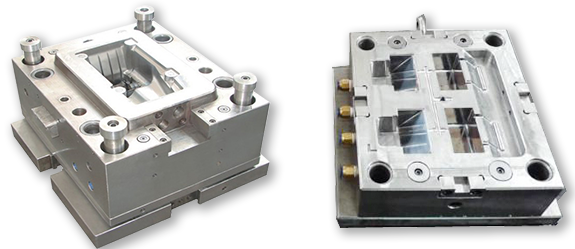

From single-function prototype injection molding, professional and complex aluminum metal injection mold design and manufacturing, to the production of small and high volume injection molded products and foundry manufacturing, GMB offers high-end diversified injection mold processes and services.

Our experienced injection mold design team has been designing and manufacturing the best metal molds and production tools for plastic injection molding companies in various industries to help customers achieve high-speed, high-quality production in their markets.

With extensive experience in the injection of complex parts requiring high precision and high precision, GMB offers a wide range of sizes and types of plastic injection molded parts and foundry manufacturing, such as daily necessities, medical and automotive parts.

Depends on the part geometry, tool design, production volumes and budget, a variety types of injection molds can be designed and manufactured to suit the different injection molding process needs of the customer, including the cold runner, hot runner, insert, blow mold, etc.

We’re proud to be one of the fastest growing Plastic Injection Mould supplier in China, have been provided top grade Injection Molds for many famous large enterprises, even entered the global market, our plastic molding products received the favor of customers from European and American countries. EX MOULD Co., Ltd is the place to go when you need a reliable molding supplier for manufacturing services. We are responsive to your ongoing requirements, look forward to earning your business and becoming your source for Injection Molding!

COMPANY NEWS

18

2025.4

All About Insert Injection Molding: Considerations, Applications

Insert injection molding is a smart way to make strong plastic parts. It mixes plastic with other solid materials like metal. This method is used in many industries, such as cars, electronics, and even medical tools. If you sell or use molded products, understanding metal inserts in injection molding can help you make better choices. We’ll talk about what insert injection molding is, how it works, and where it’s used. We will also explore the process, important th......

18

2025.4

How Do I Choose the Right Injection Blow Molding Partner

Choosing the right Injection Blow Molding partner is a big decision. The Injection blow molding company you pick will shape your product’s quality, delivery time, and cost. Whether you’re making bottles, jars, or small plastic containers, the professional blow mold manufacturer can help your business grow. But how do you find a company you can trust? This guide will help you learn what to look for in an Injection Blow Molding company. We’ll also introduce yo......

11

2025.4

Can Silicone Mold Manufacturers Create Custom Designs

Silicone molds are tools made from soft but strong materials. These molds help shape different items in many industries. You can find them in factories, homes, and even in kitchens. But what if you want a mold made just for your product? Can silicone mold manufacturers create custom designs? Yes, they can! We’ll explain how this works, who uses these molds, and how to choose the right custom silicone mold maker. We’ll also highlight a top company in China—EX MOULD......

![]()

11

2025.4

Resin Plastic Injection Molding: Types, Advantages, Applications

Have you ever wondered how plastic toys, phone cases, or car parts are made? Most of them come from a smart method called resin plastic injection molding. This method is fast, powerful, and used all around the world. It helps create strong, neat, and useful plastic items we use every day. Learn what resin plastic injection molding is, what types of resins are used, why this method is popular, and what kinds of products it helps create. What is Resin Plastic Inject......